Die-cut cylinders for die-cut substrates

A printing material and die-cutting technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of grid width limitation, poor functional reliability and poor utilization of pages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

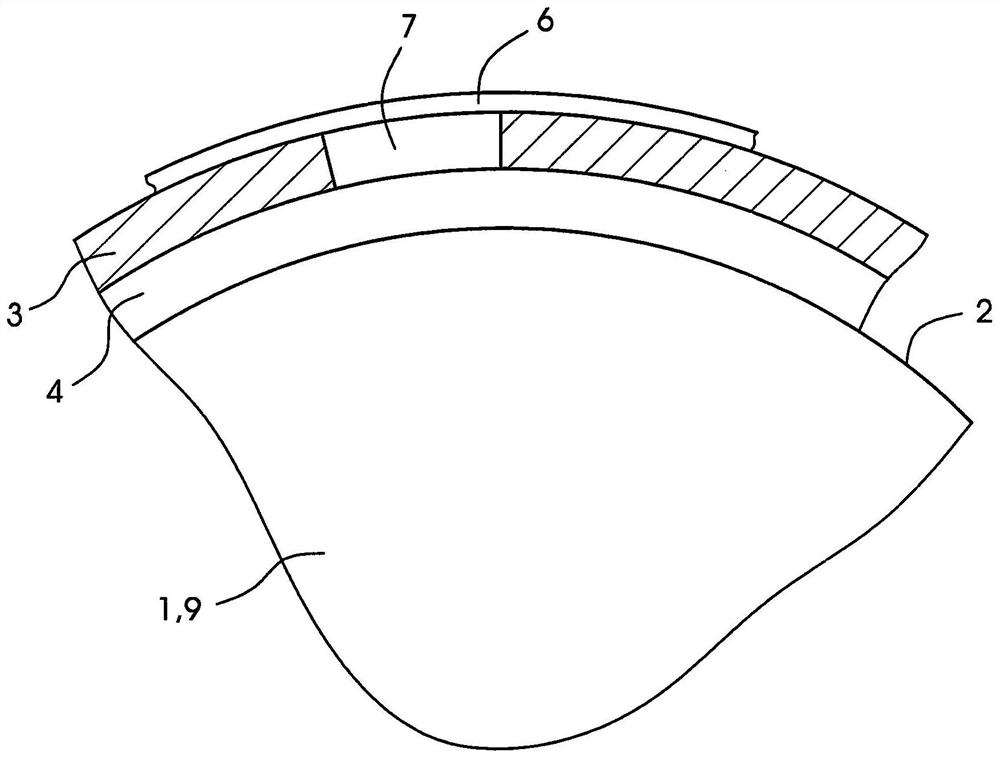

[0023] figure 1 A partial view of the die cutting roller 1 is shown. The die cutting roller 1 works with the imprint drum, and the pressurizing roller is not shown in the drawings. The die-cutting roller 1 is used to die from the printing material composed of foil or preferably paper or thick panel. The receiving material can have the shape of a web or preferred page. In the case of the piping material page, the imprinting drum has a jaw for fixed page leading edges. The die cutting roller 1 and the imprint drum are part of the die cutting station for rotating the die cut. The die-cutting station includes a suction cover that is disposed on the side of the die cutting roller on the side of the die cutting roller 1 opposite the imprint roller. The suction hood is used to collect and run away the waste sheet, the waste sheet being separated from the receiving material by the die cutting roller 1. The die-cutting station can be an integral part of a printing machine and is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com