Steel strand winding guiding device and steel strand parallel winding method

A technology for guiding devices and steel strands, which can be used in the direction of hoisting devices, erection/assembly of bridges, bridges, etc., and can solve problems such as stuck ropes and messy ropes of steel strands, and achieve good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

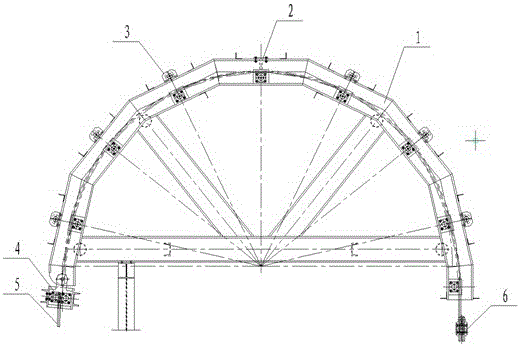

[0032] In order to overcome the problems of cumbersome installation process, high labor intensity, low efficiency and rope jamming of existing devices, the present invention provides such figure 1 A steel strand winding guide device and a side-by-side rope winding method are shown. The invention can make the whole installation process of the steel strand convenient and quick, and greatly reduce the labor intensity of construction personnel. At the same time, the guide device can well adapt to steel strands. The curvature of the strand changes, and the arrangement of the strands can also be reasonably converted, and effectively solves the problems of rope jamming and disordered ropes during the winding process of the strands.

[0033] A rope winding guide device for steel strands, comprising an arc guide frame 1, an arc-shaped frame formed by parallel and symmetrical arrangement of multiple sections of channel steel, the outside of the frame is welded with angle steel at equal i...

Embodiment 2

[0038] Based on the above embodiments, in this embodiment, the middle guide plate 2 includes a fixed plate 2.1 and a toothed comb 2.2, the fixed plate 2.1 is fixed at the center of the top of the arc guide frame 1, and the The toothed comb 2.2 is vertically located below the fixing plate 2.1, and the steel strands 5 are neatly arranged in the toothed comb 2.2.

[0039] Figure 4 It is a structural schematic diagram of the middle guide plate 2, which is installed in the middle position of the top of the arc guide frame 1 by bolts, and the steel strands 5 are arranged neatly under the horizontal combing of the toothed comb 2.2.

[0040] The end swing frame 4 includes a pin joint plate 4.1, a channel steel frame 4.2, a grooved roller 4.3, a central shaft 4.4, and a flat idler roller 4.5, and the two ends of the channel steel frame 4.2 are provided with a pin joint plate 4.1 , the flat idler 4.5 and the central axis 4.4 are arranged in parallel on the two ends of the channel stee...

Embodiment 3

[0047] Based on the above embodiments, in this embodiment, a method for side-by-side winding of steel strands is provided, and the specific steps are:

[0048] Step 1: For the top-threading method of the passive cable-releasing device and the active cable-releasing device of the steel strand, the steel strands 5 are lifted from the construction platform one by one and fixed by the upper and lower clips of the jack;

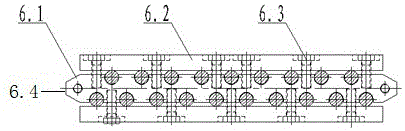

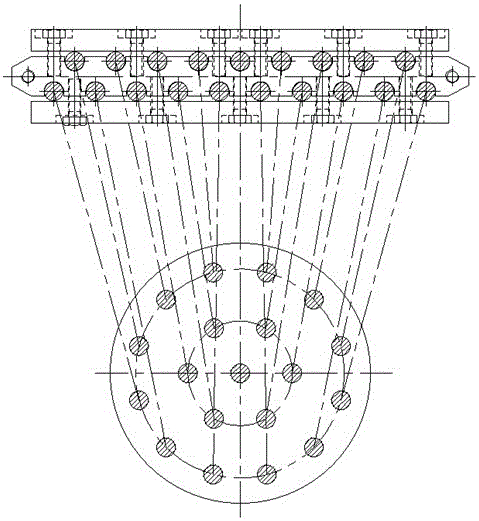

[0049] Start the hydraulic pump station, lift the reciprocating action of the jack to push the steel strand 5 to a certain position, according to the corresponding relationship of the steel strand 5, put the pair of steel strand 5 into the middle slot 6.1 of the steel strand clamping device 6 and press Tight, the steel strands 5 are arranged horizontally by circular arrangement;

[0050] The lifting jack continues to reciprocate to push the steel strand 5 slowly into the arc guide frame 1, and is gradually wound under the support of the guide wheel assembly 3 up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com