Method of extracting lignin from papermaking black liquor

A technology for papermaking black liquor and lignin, which is applied in the field of lignin extraction, can solve the problems of secondary pollution, low purity of separated lignin, etc., and achieves the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

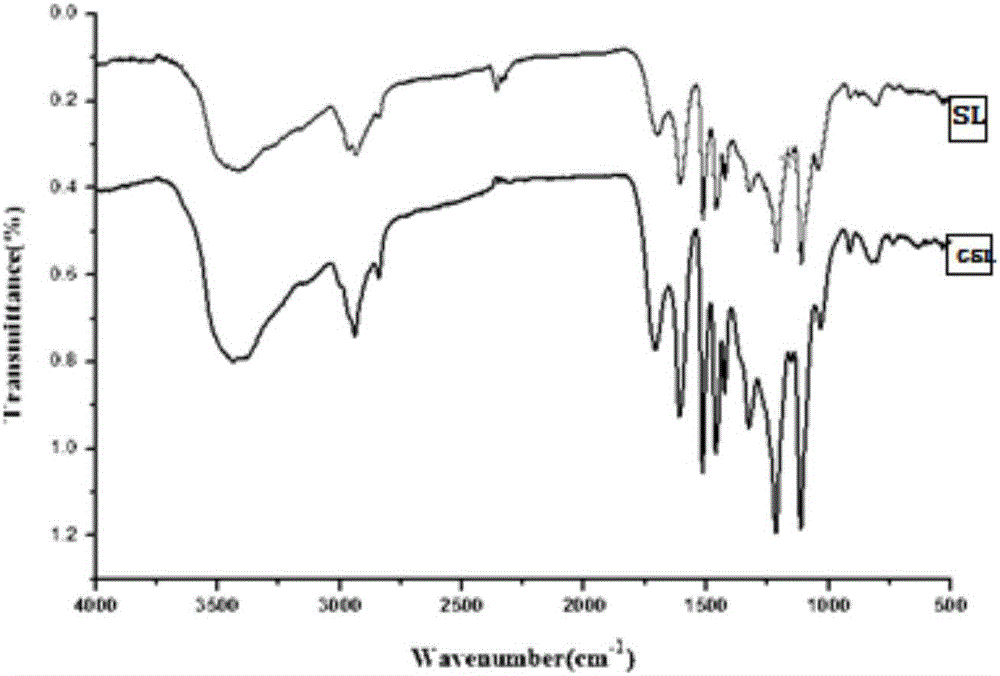

Image

Examples

Embodiment 1

[0021] The invention provides a method for extracting lignin from papermaking black liquor. Firstly, ethanol is used to remove some polysaccharide substances in the black liquor, and then the lignin is extracted with acid, so that the purity of lignin obtained will be higher. The preparation method includes the following steps: step:

[0022] Step 1. Take papermaking black liquor and absolute ethanol at a volume ratio of 1:1 and place them in a reaction kettle, shake and mix evenly to obtain a mixed liquor, and treat the mixed liquor in a water bath at 60°C for 2 hours; Purity is not high, based on this, ethanol is added in the papermaking black liquor, to separate out the polysaccharide insoluble in ethanol in the papermaking black liquor, thereby obtain comparatively pure papermaking black liquor and go to step 2;

[0023] Step 2. Pour the mixed solution after the water bath treatment into the separatory funnel, shake it for 10 minutes, and then separate into layers, and col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com