Antibacterial and deodorant EVA shoe sole foaming material and preparation method thereof

The technology of foaming material and rush powder is applied in the field of EVA shoe sole foaming material and its preparation, which can solve the problems of sole odor, foot odor and beriberi, affecting the environment of surrounding people, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

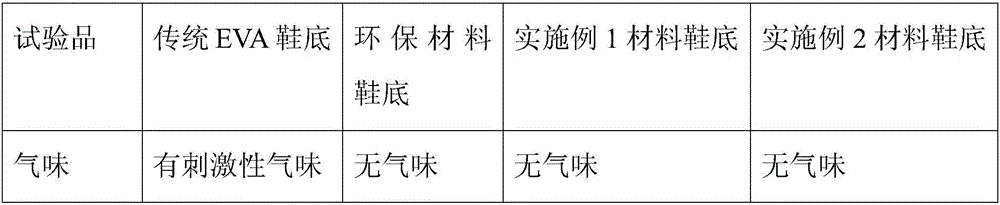

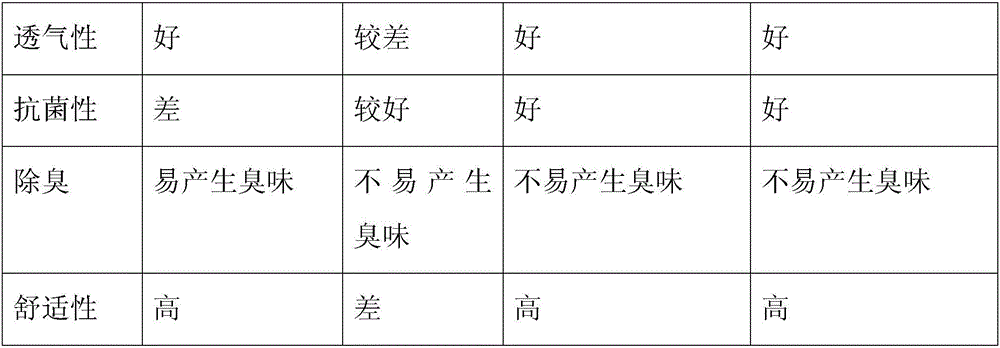

[0021] The EVA sole foaming material of embodiment 1 antibacterial deodorization and preparation method thereof

[0022] The EVA sole foaming material of antibacterial deodorization, by weight, comprises following component:

[0023] 75 parts of EVA; 0.6 parts of rush powder; 0.6 parts of antibacterial zeolite powder; 8 parts of hemp stalk powder; 1.2 parts of sulfur; 6 parts of bamboo fiber; 4 parts of filler; 3.1 parts of odorless foaming agent; 0.7 parts of zinc oxide powder; 0.3 parts of stearic acid.

[0024] The preparation method of the EVA sole foaming material of this example antibacterial deodorization comprises the following steps:

[0025] (1) weighing and mixing;

[0026] (2) Send to the internal mixer for internal mixing, the temperature is controlled at 110°C-115°C, the air pressure is 0.65-0.8kg, and the internal mixing time is 8-9 minutes;

[0027] (3) Send the mixture obtained from banbury mixing into the open mill to start mixing, the temperature is contr...

Embodiment 2

[0031] The EVA sole foaming material of embodiment 2 antibacterial deodorization and preparation method thereof

[0032] The EVA sole foaming material of antibacterial deodorization, by weight, comprises following component:

[0033] 74.9 parts of EVA; 1.1 parts of rush powder; 0.6 parts of antibacterial zeolite powder; 8 parts of hemp stalk powder; 0.6 parts of sulfur; 5.5 parts of bamboo fiber; 4.5 parts of filler; 0.6 parts of zinc oxide powder; 0.2 parts of stearic acid.

[0034] The preparation method of the EVA sole foaming material of this example antibacterial deodorization comprises the following steps:

[0035] (1) weighing and mixing;

[0036] (2) Send to the internal mixer for internal mixing, the temperature is controlled at 110°C-115°C, the air pressure is 0.65-0.8kg, and the internal mixing time is 8-9 minutes;

[0037] (3) Send the mixture obtained from banbury mixing into the open mill to start mixing, the temperature is controlled at 82°C to 88°C during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com