Single-well multi-layer simultaneous injection recovery technique string

A process pipe string and pipe string technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of high operation cost, many intermediate operation links in stages, and low oil production time efficiency, so as to improve oil production. The effect of aging and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

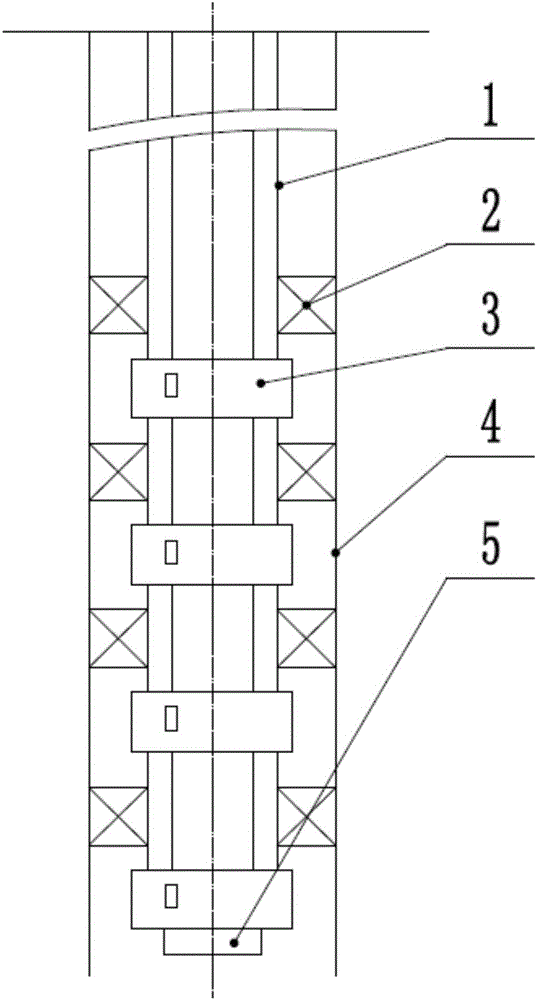

[0011] Such as figure 1 As shown, a single-well multi-layer simultaneous injection-production process string includes a dual-channel string 1; the dual-channel string 1 is composed of two independent channels, and the dual-channel string 1 and the dual-channel liquid flow exchange The devices 3 are alternately connected from top to bottom, and the lower end of the dual-channel liquid flow exchanger 3 is connected to the multi-functional steering head 5. The multi-functional steering head 5 can cooperate with the interlayer packer 2 in addition to the guiding function of the pipe string running in. Meet various sealing requirements. Interlayer packers 2 are respectively installed on the dual-channel tubing string 1 at the upper and lower ends of the dual-channel liquid flow exchanger 3, and the outer side of the dual-channel tubing string 1 and the technical casing 4 are sealed by the interlayer packer 2 so that each double-channel The channel liquid flow exchanger 3 is locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com