A kind of production method of biodiesel grease

A biodiesel and production method technology, applied in the chemical industry, can solve the problem of high cost, and achieve the effects of eliminating pretreatment costs, saving land and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

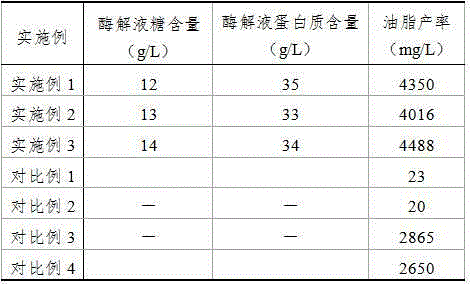

Examples

Embodiment 1

[0020] The oil-rich chlorella algae species were inoculated into sterile f / 2 medium through aseptic operation, placed in a light incubator, culture temperature 25°C, light intensity 2000lx, culture for 10 days. The oil-rich Cryptococcus flexus strains were inoculated into sterile shake flask culture solution (mg / L): yeast extract 3000, malt extract 3000, peptone 5000 and glucose 20000, placed in a shaker. Cultivation in bed, rotation speed 200 rpm, culture temperature 35°C, culture for 72 hours. 50g of oil-rich chlorella grown in a light incubator and 50g of oil-rich Cryptococcus curvy fermented in a shaker were centrifuged (8000 rpm, 10 minutes) to collect the biomass and rinsed with distilled water for 5 Times. Pretreatment with cytolytic enzyme L2524-25KU: oleaginous microbial biomass (dry matter) and cytolytic enzyme L2524-25KU are mixed at a mass ratio of 100:1, 45°C, initial pH 6.0, stirring speed 150 rpm ,4 hours. Use n-hexane and ethanol to extract oil and fat. The v...

Embodiment 2

[0024] The oil-rich prokaryotic chlorella algae was inoculated into sterile f / 2 medium through aseptic operation, and placed in a light incubator for culture at a culture temperature of 28° C. and a light intensity of 5000 lx for 10 days. Inoculate the oil-rich Rhodotorula glutinosa strain into the sterile shake flask culture medium through aseptic operation: 1000mL potato extract (peel 200g potatoes, cut into small pieces, add water and boil for 1 hour, filter with 5 layers of gauze, and dilute to 1000mL ) And glucose 20000mg / L, cultured in a shaker, rotating speed 150 rpm, culture temperature 37 ℃, culture for 72 hours. Separately, 50g of oil-rich Prokaryotic Chlorella grown in a light incubator and 50g of oil-rich Rhodotorula glutinosa fermented in a shaker were centrifuged (8000 rpm, 10 minutes) to collect the biomass and rinse with distilled water 5 times. Pretreatment with cytolytic enzyme L2524-10KU: oleaginous microbial biomass (dry matter) and cytolytic enzyme L2524-1...

Embodiment 3

[0028] The oil-rich Pseudochlorococcum algae species were inoculated into sterile f / 2 medium through aseptic operation, placed in a light incubator, culture temperature 25°C, light intensity 2000lx, culture for 10 days. The oil-rich Mortierella alpina was inoculated into a sterile shake flask culture medium (mg / L): yeast extract 10000, peptone 10000 and glucose 30,000, cultured in a shaker at 180 revolutions / Min, culture temperature 37°C, culture for 72 hours. Separately, 50g of oil-rich Pseudochlorococcum grown in a light incubator and 50g of oil-rich Mortierella alpina fermented in a shaker were centrifuged (8000 rpm, 10 minutes) to collect the biomass and rinse with distilled water 5 times. Pretreatment with cytolytic enzyme L4025-100KU: oleaginous microbial biomass (dry matter) and cytolytic enzyme L4025-100KU are mixed at a mass ratio of 50:1, 45°C, initial pH 6.0, and stirring speed 150 rpm ,4 hours. Use n-hexane and ethanol to extract oil and fat. The volume ratio of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com