Tension-adjustment dual-roller-set correction packing box

A technology of tension adjustment and packing box, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc. It can solve the problems of reduced sealing effect, inaccurate centering of polished rods, and damage to the surface finish of oil production polished rods, etc., to reduce frictional strength and fatigue damage, improve oil production efficiency, and save oil production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

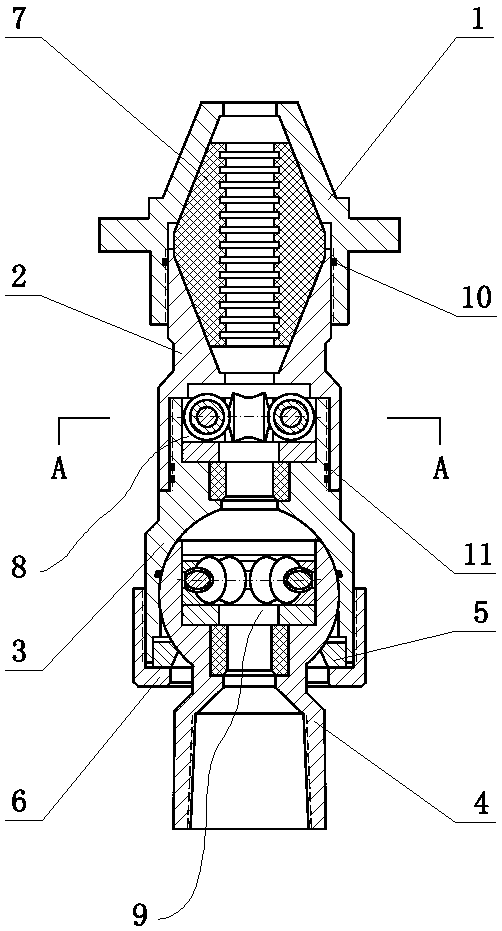

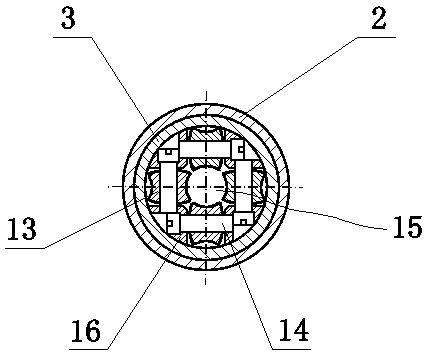

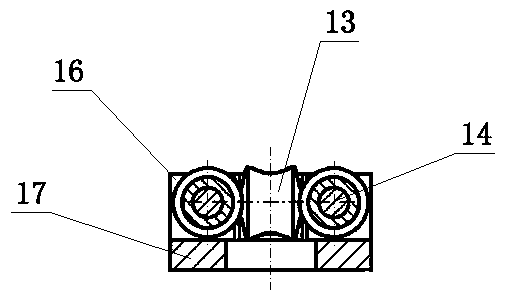

[0018] Taking a tension-adjusting deviation-correcting packing box composed of four rollers as an example, the technical solution claimed in the present invention will be further described in conjunction with the accompanying drawings.

[0019] A tension-adjusting double-roller group correcting packing box, such as figure 1 As shown, the main body of the packing box 2, the upper gland 1, the rubber packing 7, the lower joint 3, the ball joint 4, the ring clamp 5, the lower gland 6, the first roller group 8 and the second roller group 9 composition.

[0020] The upper part of the packing box main body 2 is screwed and fixedly connected with the upper gland 1, the lower part of the packing box main body 2 is screwed and fixedly connected with the lower joint 3, and at the lower part of the lower joint 3, through the ring clip The structure of the hoop 5 and the lower gland 6 is matched and connected with the ball joint 4, wherein the annular hoop 5 is inserted between the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com