Management planning and scheduling execution system for production manufacturing site

An execution system and planning technology, applied in manufacturing computing systems, data processing applications, devices for collaborative operations, etc., can solve the problem of not providing direct and detailed support for workshop-level management processes, and improve product quality and reduce costs. , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

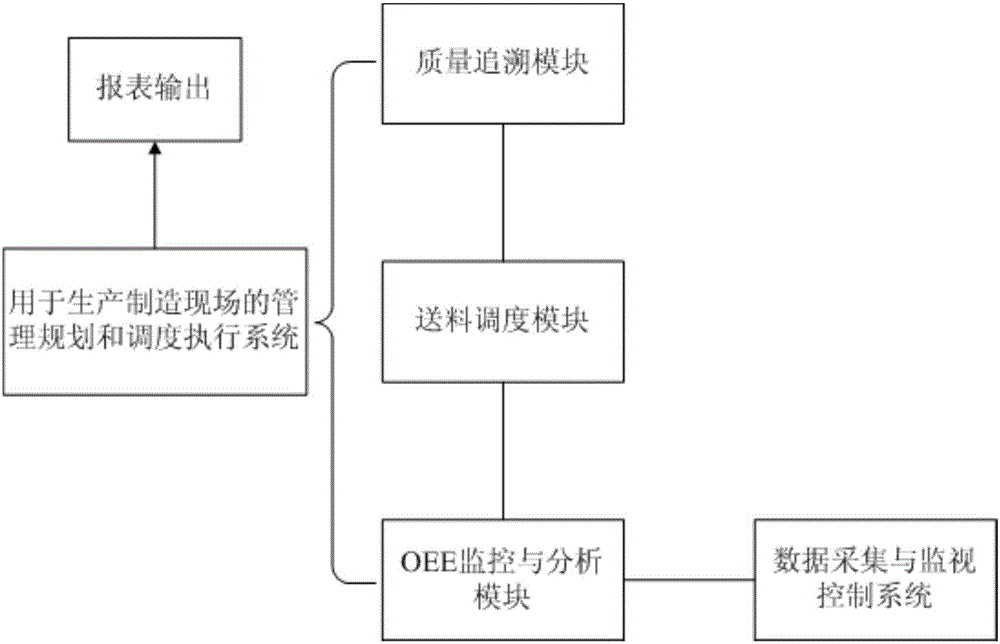

[0023] as attached figure 1 As shown, a management planning and scheduling execution system for the manufacturing site mainly includes three modules, namely the material feeding scheduling module, the quality traceability module and the OEE (Overall Equipment Effectiveness) monitoring and analysis module.

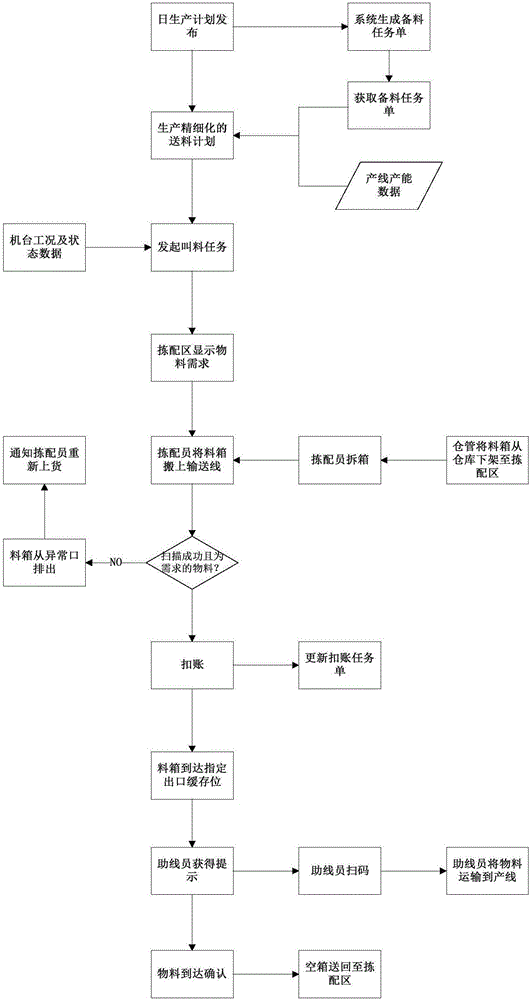

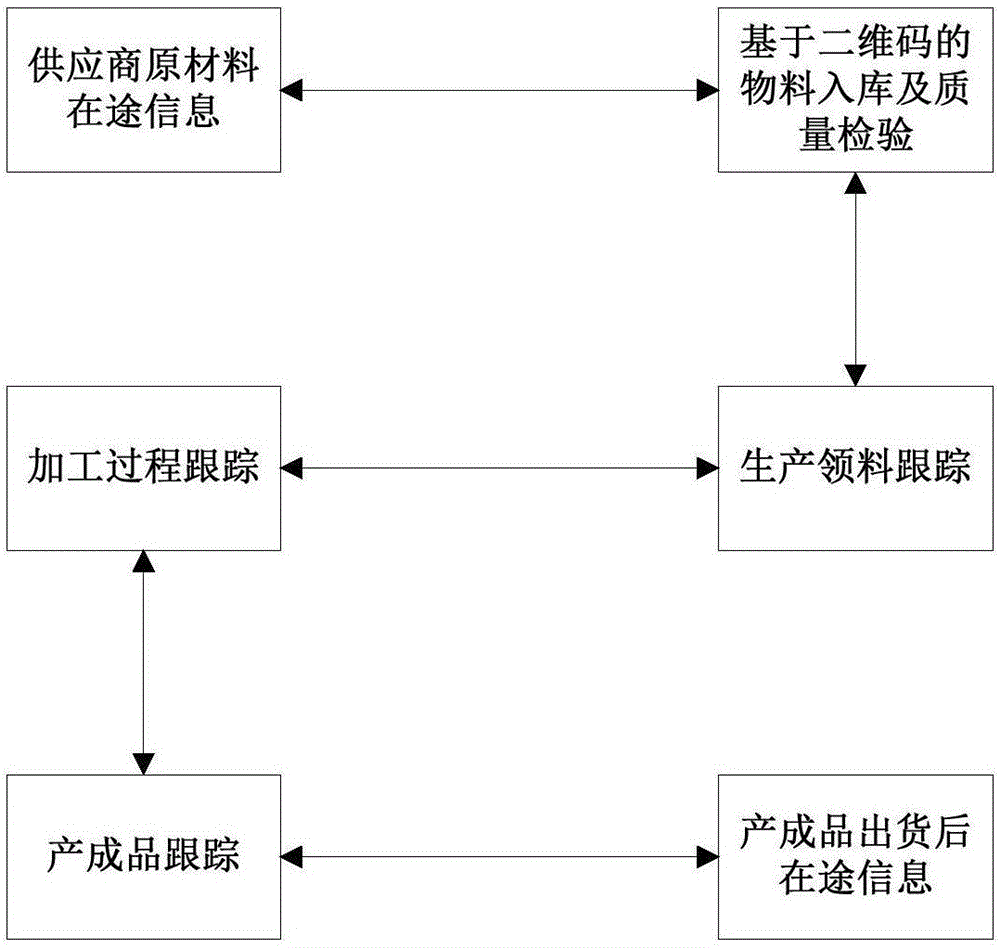

[0024] Among them, the material feeding scheduling module is the basis of the entire system, and the quality traceability module and OEE monitoring and analysis module will realize the monitoring and management of the entire material feeding scheduling process. After the user initiates the feeding process, the quality traceability module will monitor the quality of the materials during the entire feeding process, and trace back to the source of the unqualified materials at the first time. Waste statistics are used to obtain equipment perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com