Proteases for high protein fermented milk products

一种蛋白酶、发酵奶的技术,应用在奶配制品、奶油配制品、酶等方向,能够解决工艺特性加工、质地和流变学变化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0299] The present disclosure is described in further detail in the following examples, which are not intended to limit the scope of protection claimed by the present disclosure in any way. The accompanying drawings are intended to be considered an integral part of the specification and description of this disclosure. The following examples are offered to illustrate but not limit the claimed disclosure.

example 1

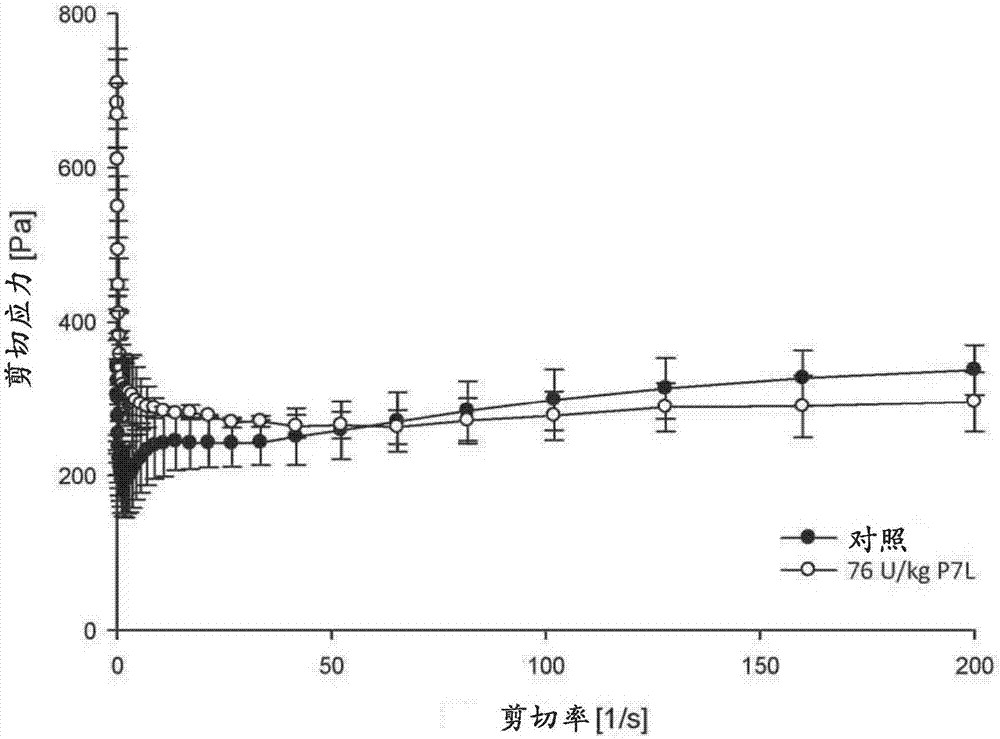

[0301] The purpose of the following example is to reduce the viscosity of the high protein yogurt. To standardize the milk to a protein content of 10% (w / v), skim milk powder and Milk protein 70 were used. Different amounts of Protex 7L (P7L) and Protex 6L (P6L) were added to the yoghurt before or after pasteurization in order to test the optimum conditions to reduce the viscosity of the yoghurt. Fermentation was carried out using YM 860 and YM410 at 43°C to a final pH of 4.6. High protein yoghurt produced with YM 860 showed an overall better appearance than yoghurt fermented with YM 410. For the protein sources used, milk protein 70 showed better properties in terms of yoghurt general texture and less off-flavors than yoghurt from milk standardized with SMP. The best results related to enzyme addition were shown after pasteurization when P7L was added at doses >22.4U / kg. Addition of 80 U / kg P7L to yogurt standardized with MP70 resulted in a 30% reduction in shear stress, t...

example 2

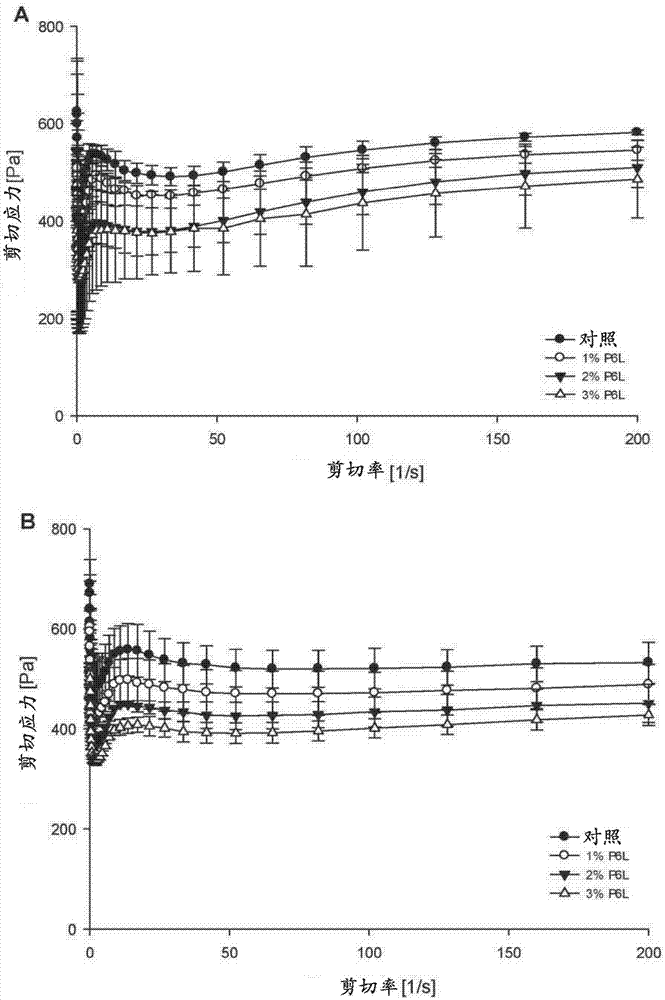

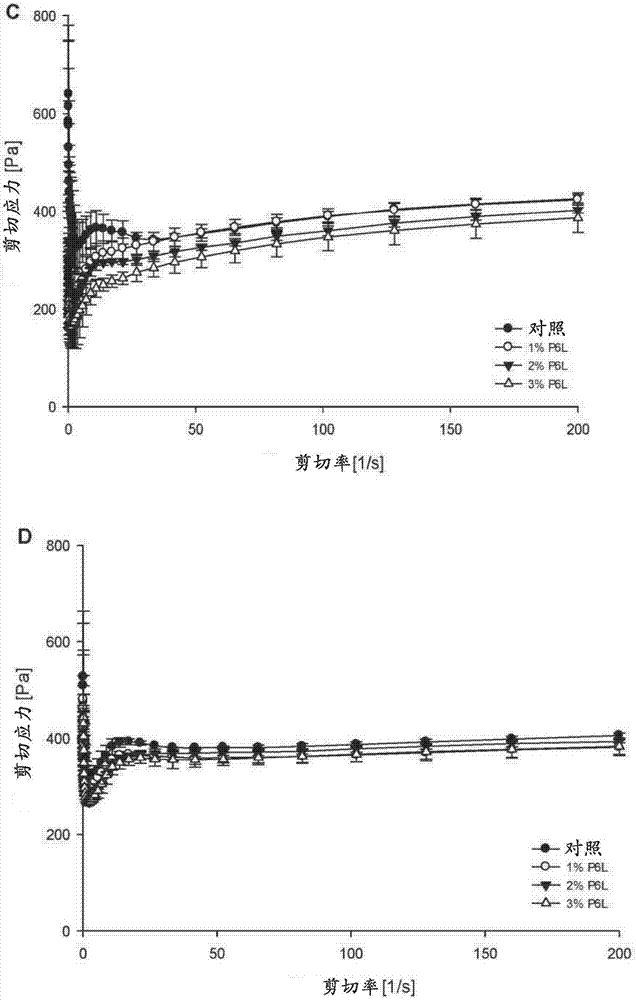

[0334] The purpose of this instance is to produce a smoother high protein yogurt.

[0335] Measurement temperature / hold time during processing:

[0336]

[0337]To standardize the milk to a protein content of 10% (w / w), milk protein 70 was applied. Different amounts of Protex 7L and Protex 6L were added to the yoghurt before or after pasteurization in order to test the optimum conditions for producing a smoother high-protein yoghurt. Fermentation was performed using YM 860 at 43°C to a final pH of 4.6.

[0338] Materials and Methods

[0339] Lab-scale production of stirred yogurt samples

[0340] Milk protein (MP 70) and cream (38% (w / w); Arla, Viby, Denmark) were added to skimmed milk (0.1% (w / w) fat; Arla Arla, Viby, Denmark) in order to standardize the milk to a protein content of 10% (w / w) and a fat content of 1.5% (w / w). The milk was mixed at 45°C with good agitation. Add Protex 6L before pasteurization and homogenization at 95°C for 6 minutes (P1: 65°C; homogeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com