Patents

Literature

36results about How to "Guaranteed acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

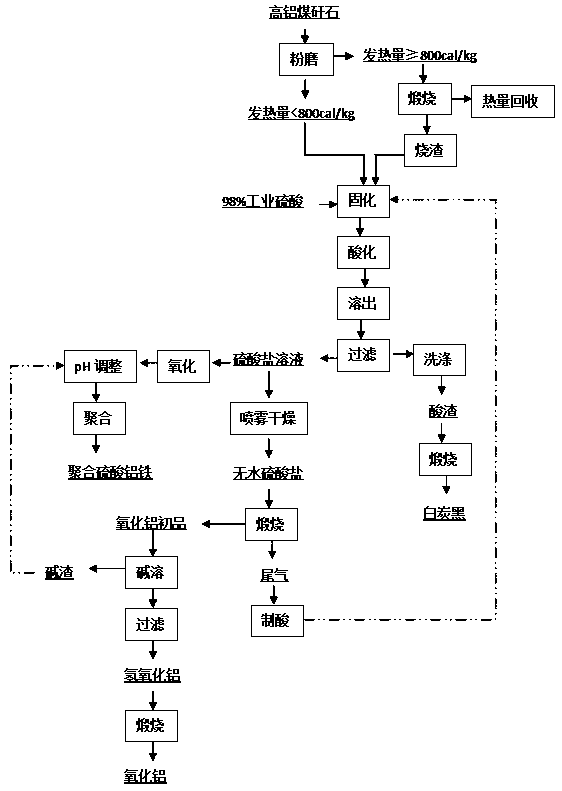

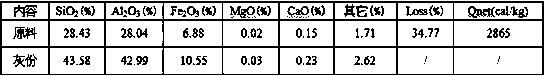

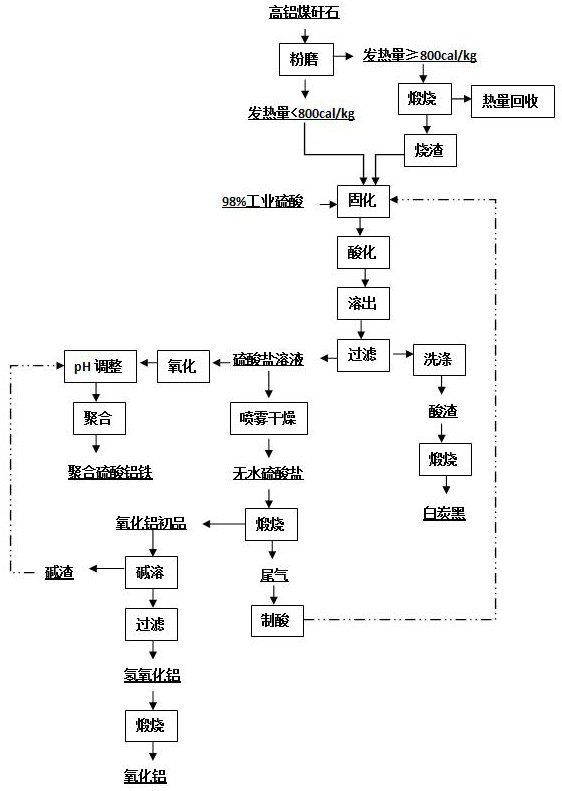

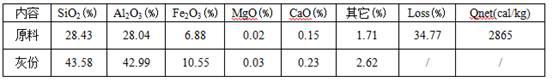

Method for efficiently utilizing high-aluminum gangue

ActiveCN108975367AResolve transferSolve operational problemsAluminium compoundsSilicaAluminium sulfateResource utilization

The invention discloses a method for efficiently utilizing high-aluminum gangue, and belongs to the technical field of resource utilization of industrial solid waste. The method comprises the following steps: curing after adding acid in gangue or cinder, and then acidifying, dissolving out, filtering and washing, thus obtaining a sulfate solution which mainly contains aluminum sulfate and silicon-enriched acid sludge in which impurities are removed, wherein the sulfate solution is used for preparing aluminum hydroxide or aluminum oxide and polyaluminum sulfate products, and white carbon blackcan be generated by roasting the acid sludge. The method disclosed by the invention is reasonable in the resource utilization, no new solid waste emission is generated, the market constant of the products is large, and a feasible method can be provided for resource utilization of the high-aluminum gangue.

Owner:KUNMING UNIV OF SCI & TECH +1

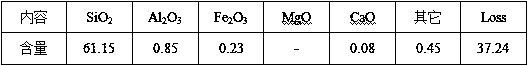

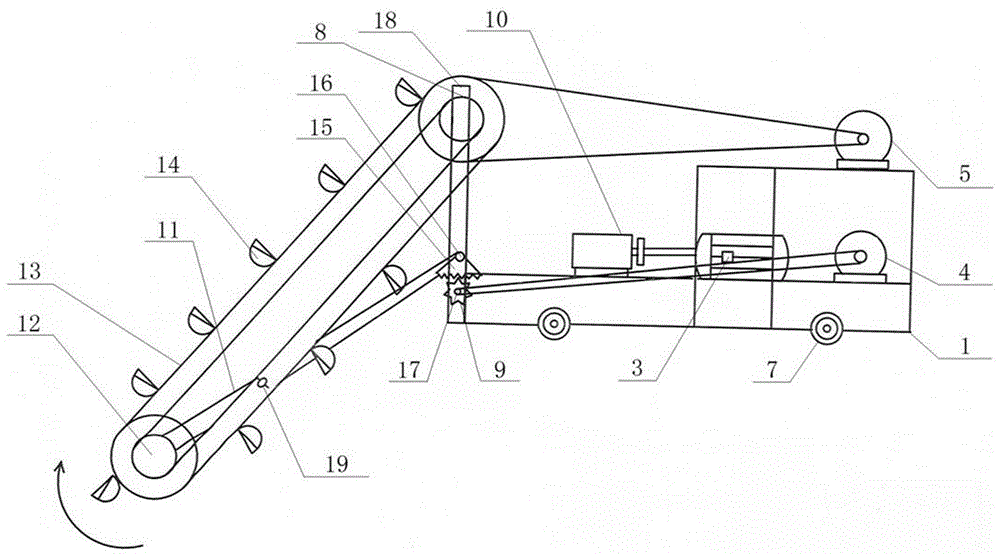

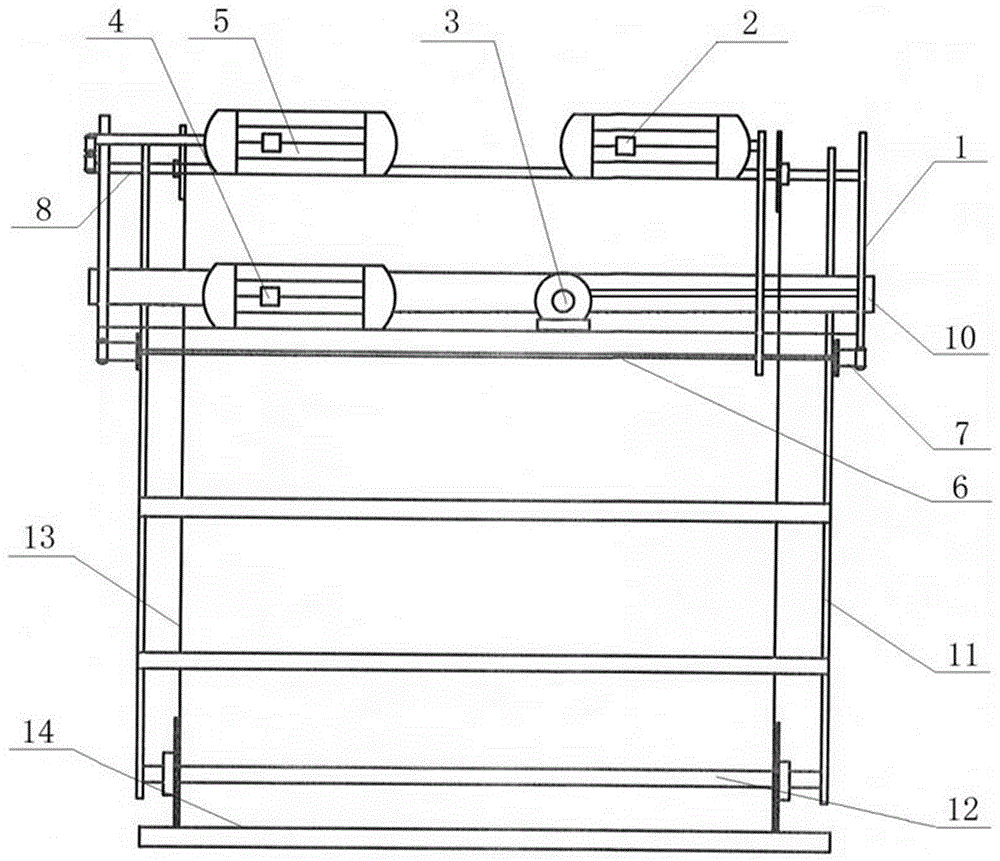

Mechanized production technique for mature vinegar by solid-state acetic acid fermentation

ActiveCN106635735AIncrease enzyme activityLess irritatingMicroorganism based processesVinegar preparationFlavorAcetic acid

The invention provides a mechanized production technique for mature vinegar by solid-state acetic acid fermentation. A machine for stirring fermented grains is used to mix wine mash obtained after an thick mash alcoholic fermentation is ended, accessories and multi-microbe mouldy bran; a conveyor belt conveys materials into a stainless steel long-strip-shaped acetic acid fermentation vat for performing later solid-state alcoholic fermentation; then fire-fermented grains mixed with lactic acid bacteria is added for performing multi-microbe acetic acid fermentation; a temperature control type machine for automatically stirring and pouring the fermented grains is used to replace manpower for stirring and tank pouring of the fermented grains. The prepared multi-microbe mouldy bran and the lactic acid bacteria are added in a preparation process, so the physical appearance and flavor of a product are improved.

Owner:SHANXI ZILIN VINEGAR

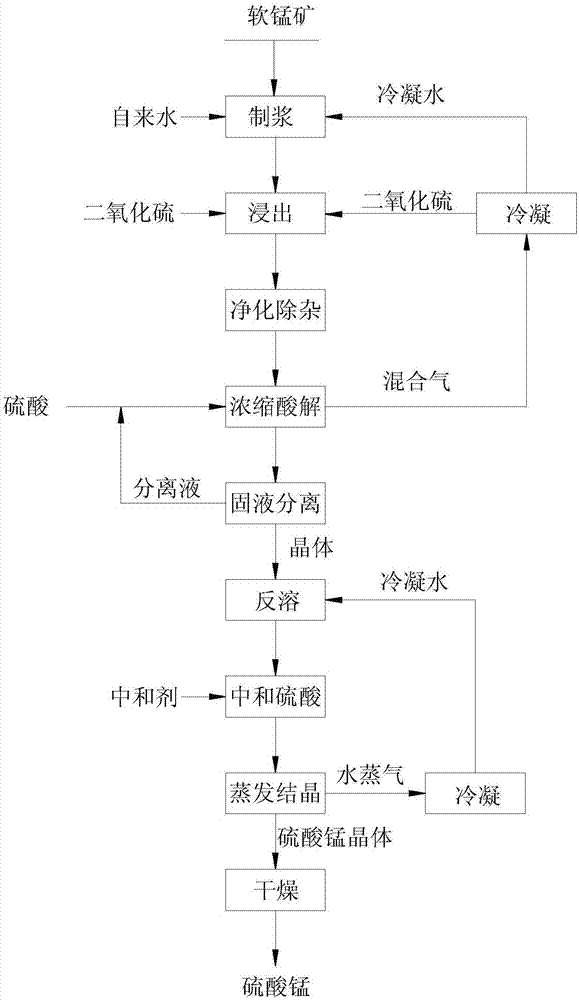

Method for removing manganous dithionate in pyrolusite slurry leaching solution to prepare saturated manganese sulfate slurry and manganese sulfate

ActiveCN107445209AProcess flow is easy to operateHigh resource utilizationManganese sulfatesHeavy metalsDithionate

The invention provides a method for removing manganous dithionate in a pyrolusite slurry leaching solution to prepare saturated manganese sulfate slurry and manganese sulfate. The method comprises the following steps: performing solid-liquid separation to obtain pyrolusite slag and a separated solution containing manganese sulfate and manganous dithionate; performing neutral oxidation on the separated solution to remove iron and aluminum; vulcanizing to remove heavy metal; heating an obtained mixed solution of manganese sulfate and manganous dithionate to evaporate and concentrate to obtain a crystal-containing saturated solution; adding sulfuric acid or a saturated manganese sulfate solution containing sulfuric acid to decompose manganous dithionate into manganese sulfate and sulfur dioxide; discharging mixed gas of sulfur dioxide and water vapor to obtain the saturated manganese sulfate slurry without the manganous dithionate. The invention also provides a method for preparing manganese sulfate through the saturated manganese sulfate slurry prepared by the method. The method is low in cost, easy to operate, and capable of removing manganous dithionate in the leaching solution without additional subsequent purifying process, and high-level manganese sulfate product is prepared.

Owner:SICHUAN UNIV

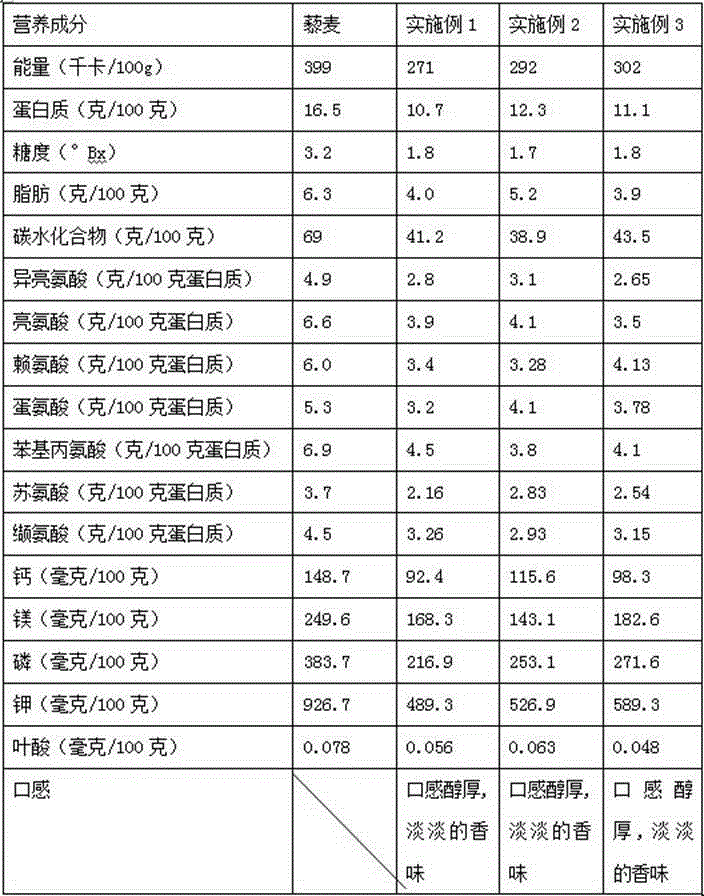

Chenopodium quinoa wine and method for preparing same

InactiveCN106635637AReduce the temperatureImprove stabilityAlcoholic beverage preparationYeastAlcohol content

The invention discloses chenopodium quinoa wine and a method for preparing the same. Brewing raw materials for the chenopodium quinoa wine include, by weight, chenopodium quinoa, yeast and baijiu with the alcohol content of 65%vol. A weight ratio of the three brewing raw materials is 5:1:10-15, the yeast is made of chenopodium quinoa, barley and peas, and a weight ratio of the chenopodium quinoa to the barley to the peas is 5:3:2. The chenopodium quinoa wine and the method have the advantages that nutritional components in the chenopodium quinoa can be sufficiently decomposed and can be dissolved in the chenopodium quinoa wine, and accordingly nutritional value of wine can be enhanced.

Owner:张宏

High self-cleaning inorganic heat insulation composite system

InactiveCN102304965AImprove insulation effectImprove cohesionCovering/liningsClimate change adaptationInsulation layerEmissivity

The invention relates to a high self-cleaning inorganic heat insulation composite system comprising a substrate wall body, as well as interface mortar, a heat insulation layer, an anti-cracking protection layer and a veneer layer in sequence from the substrate wall body to the outside. The invention has the advantages of simple structure, comprehensive functions, favorable heat insulation effect, strong anti-cracking and shock resistance, obvious fireproof and antiflaming effect, favorable high temperature stability, high self-cleaning and the like. Anti-cracking mortar is selected for the anti-cracking protection layer and alkaline-resistant fiberglass gridding cloth or an AJ hot zinc-plating electrowelding net is arranged in the mortar, therefore, the anti-cracking and shock resistant effects are better; the polystyrene particles of the heat insulation layer are made from recycled polystyrene plates, therefore, the processing is simple, a large number of white pollution can be solved, and the heat insulation property of the material can be greatly improved due to excellent heat insulation property of the polystyrene particles per se; and an energy-saving coating material has the advantages of favorable visible light and near infrared light reflectivity, higher thermal infrared emissivity, excellent high temperature stability, high intensity, high temperature resistance, wear resistance, high tenacity, convenience for construction and cost saving.

Owner:青岛格尔美环保涂料有限公司

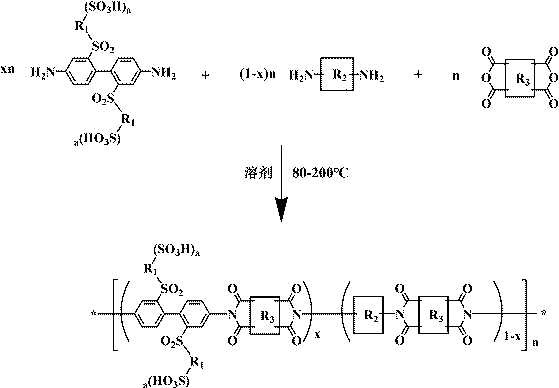

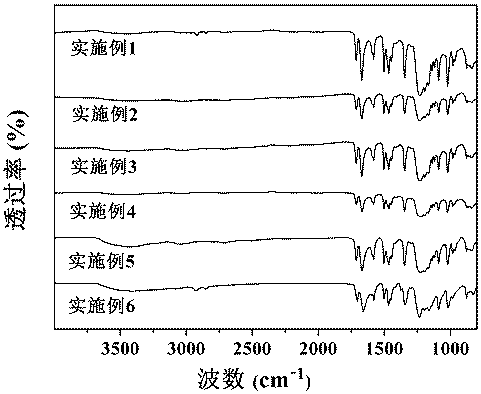

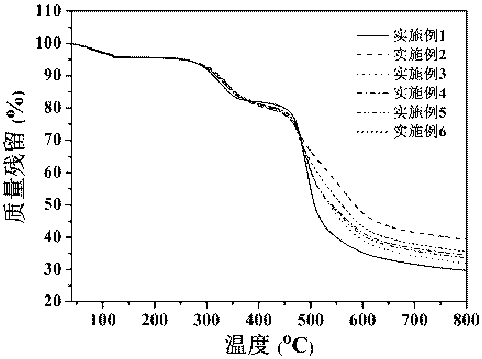

Sulfuryl bridge connection side chain sulfonated polyimide, preparation method thereof and application

InactiveCN107417915AGuaranteed flexibilityImprove hydrolytic stabilityFinal product manufactureFuel cellsPolymer scienceBackbone chain

The invention discloses sulfuryl bridge connection side chain sulfonated polyimide, a preparation method thereof and a method for preparing proton exchange membranes by applying the sulfonated polyimide. The sulfuryl bridge connection side chain sulfonated polyimide is structurally characterized in that a side chain with a sulfonic acid group is connected onto a polyimide main chain through sulfuryl serving as a bridge connection group, the sulfuryl serves as the bridge connection group, so that flexibility of the side chain and acidity of the sulfonic acid group are ensured, and an obtained polymer has high molecular weight and good hydrolytic stability. A preparation process of the sulfonated polyimide is simple and applicable to industrial production, and reaction conditions are easily operated and controlled. The proton exchange membranes prepared by the sulfuryl bridge connection side chain sulfonated polyimide have high proton conductivity and potential application prospects.

Owner:张远男

Fast fermentation method of green leaf mustard

ActiveCN104770696AFast filtrationPromote fermentationClimate change adaptationFood preparationLactobacillusSalt water

The invention discloses a fast fermentation method of green leaf mustard. The fast fermentation method comprises three procedures including pretreatment, salting and sealing of a pool, wherein the salting procedure also comprises four substeps of salting lower green leaf mustard, adding auxiliary materials and aged salt water, crudely extracting myrosase and adding lactic acid bacteria. The fast fermentation method disclosed by the invention has the advantages that due to addition of glucose, the concentration of substrates can be increased, the growth factors of the lactic acid bacteria can be increased and the growth of the lactic acid bacteria can be accelerated; the green leaf mustard contains myrosinase for inhibiting the growth of the lactic acid bacteria, and due to addition of the myrosase, the myrosinase can be damaged and the fast fermentation of the green leaf mustard can be promoted; since the naturally-fermented lactic acid bacteria is insufficient, the acidity of the salted green leaf mustard can be increased. The fast fermentation method disclosed by the invention has the characteristics that the fermentation of the lactic acid bacteria can be accelerated, the acidity of the leaf mustard can be increased and the salting and fermentation time for the leaf mustard can be shortened.

Owner:四川省味聚特食品有限公司

Peach tree planting method on hillside

ActiveCN105359913AHigh sweetnessPrevent quality degradationBio-organic fraction processingExcrement fertilisersGelatin spongeSweetness

The invention provides a peach tree planting method on a hillside. The method comprises the following steps of (1) preparing before planting, (2) planting, including planting peach tree seedlings in various cement framework groups on a hillside from the bottom to the top according to a height gradual increase order, and (3) applying fertilizer, wherein in the fertilizer applying step, one month after plantation, a plurality spherical gelatin sponge are placed around a root of each peach tree seedling; a sunward hillside with the gradient of 37 to 45 degrees is selected; peach tree seedlings are planted in various cement framework groups on a hillside from the bottom to the top according to the height gradual increase order; the peach tree seedlings are distributed in a step shape to ensure the peach tree seedlings to enjoy the sunshine to the largest extent; with thorough sunniness, peach sweetness can be enhanced; a problem of peach quality decrease due to uneven sunniness acquired by peach trees planted on a flat land and lack of sunniness to lower sides of the peach trees can be solved; and hillside stability can be improved when the peach trees are planted on the hillside.

Owner:哈威光电科技(苏州)有限公司

Method for planting orange trees on mountain slope

ActiveCN105453976AHigh sweetnessPrevent quality degradationExcrement fertilisersAmmonium nitrate fertilisersOrange TreeSweetness

The invention provides a method for planting orange trees on a mountain slope. The method comprises the following steps of (1) preparation before plantation, (2) plantation, including planting orange tree seedlings in different cement frameworks along the mountain slope from the bottom to the top according to an order of orderly increased height, and (3) fertilizer application, including placing a plurality of spherical gelatine sponge surrounding a root of each orange tree. The mountain slope is sunward with gradient from 37 to 45 degrees; the orange tree seedlings with various heights are orderly planted in different cement frameworks from the bottom to the top along the mountain slope according to the order of increased height; the orange tree seedlings can be distributed in a step shape and sunlight is ensured for orange tree seedlings to the largest extent; with adquate sunniness, orange sweetness can be increased; a problem of low quality of oranges due to uneven sunlight when orange trees are planted on the flat land and leaves of the lower side of the orange trees cannot be illuminated; and mountain slope stability can be enhanced with the orange trees planted on the mountain slope.

Owner:重庆橙杨生态农业有限公司

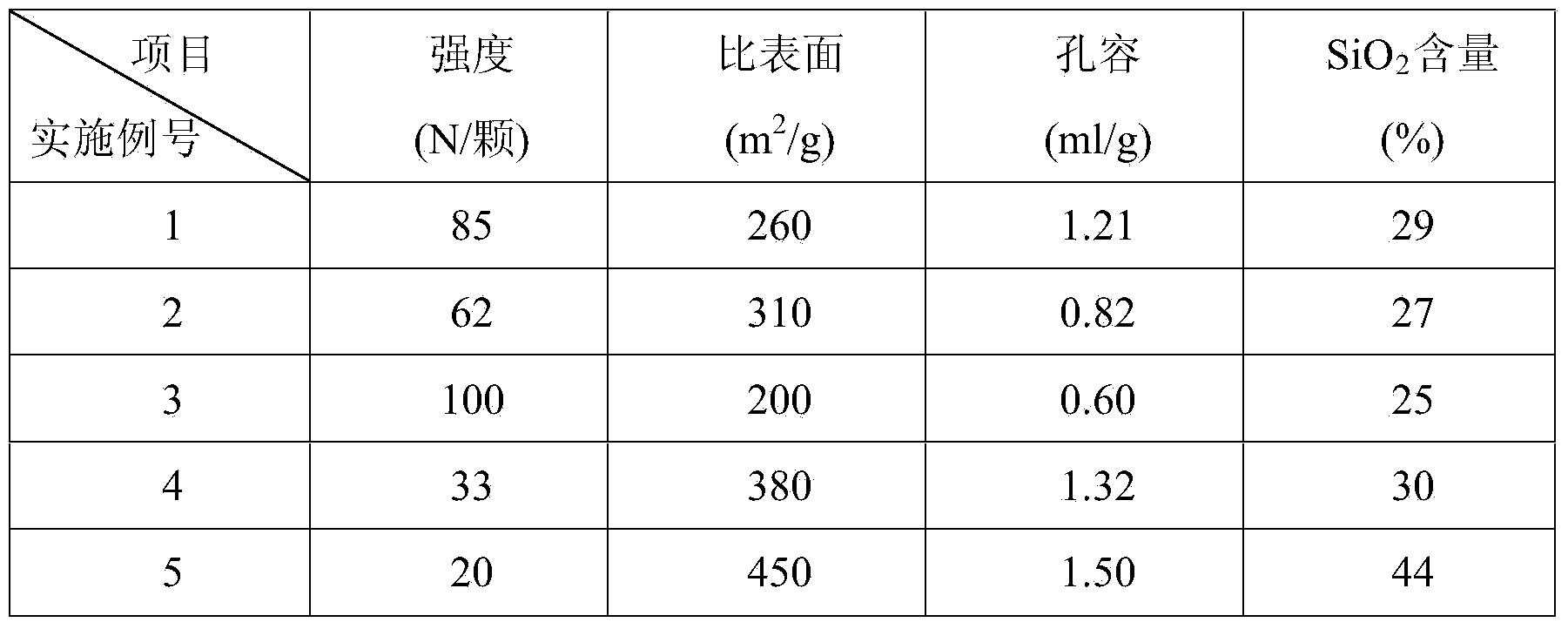

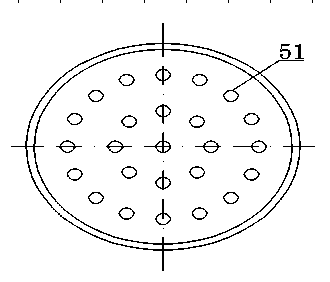

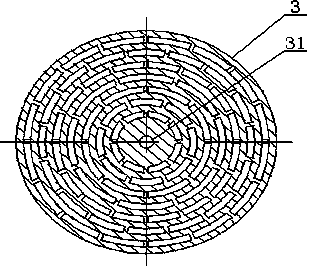

Method for preparing spherical amorphous silicon aluminum carrier

ActiveCN103861659ASuitable specific surfaceAppropriate pore volumeCatalyst carriersIonAluminum composites

The invention relates to a method for preparing a spherical amorphous silicon aluminum carrier. The method is characterized by comprising the following steps: firstly, preparing a filter cake containing an amorphous silicon aluminum composite oxide by using a neutralization method; secondly, adding a sodium alginate water solution to obtain an amorphous silicon aluminum composite oxide-sodium alginate suspension, dropwise adding the silicon aluminum composite oxide-sodium alginate suspension into a water solution containing divalent or trivalent metal ions with certain concentration, and gelling to form small amorphous silicon aluminum composite oxide-alginate composite balls; finally, washing, drying and roasting the small amorphous silicon aluminum composite oxide-alginate composite balls to obtain the spherical amorphous silicon aluminum carrier. According to the method, the spherical amorphous silicon aluminum carrier is prepared by directly molding the amorphous silicon aluminum composite oxide filter cake in a mild water phase, and only drying and roasting the filter cake once; the spherical amorphous silicon aluminum carrier is low in energy consumption, pollution-free and simple in preparation process, convenient to operate and easy to realize industrial production.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

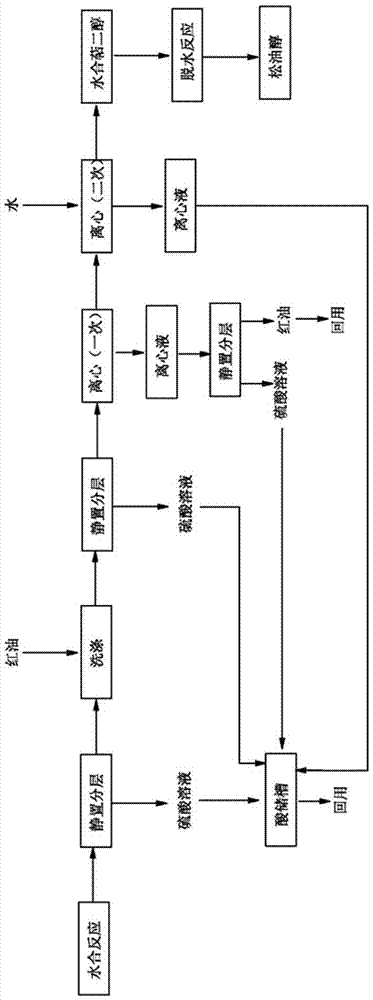

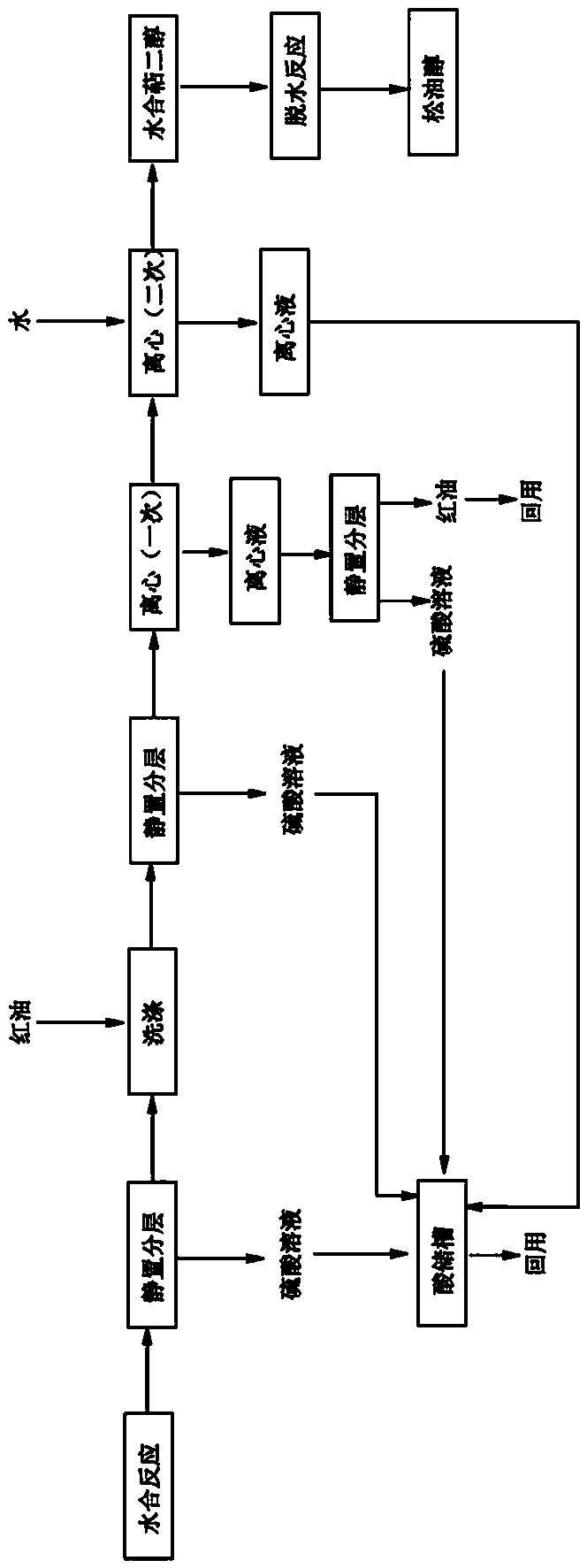

Green terpin hydrate and terpilenol production methods

ActiveCN106966860ADoes not affect compositionImprove general performanceOrganic compound preparationPreparation by OH group eliminationHydration reactionAcid water

The invention discloses a green terpin hydrate production method. The green terpin hydrate production method comprise the step of adding sulfuric acid and turpentine to perform hydration reaction and is characterized in that the heterogeneous product (red oil) collected in other bathes and produced through side reaction in the sulfuric acid and turpentine hydration reaction is added into a reaction material obtained after hydration reaction for washing, the material is subjected to standing and precipitation to remove acid water after washing. The invention further discloses a green terpilenol production method. The green terpilenol production method comprises the step of generating the terpin hydrate through hydration reaction and is characterized in that the step of generating the terpin hydrate through hydration reaction is achieved by adopting the green terpin hydrate production method. According to the green terpin hydrate and terpilenol production methods, the red oil produced in side reaction is utilized to perform washing in a hydration process, a little amount of clear water is used for washing in a centrifugation process, all the collected acid water is reused without discharging, and green production of acid water products is achieved.

Owner:FUJIAN SENFA BIOTECH

Preparation method of Hmong white sour soup

The invention discloses a preparation method of Hmong white sour soup. The preparation method comprises the following operation steps: step I, washing fresh rice produced at this year, soaking and smashing, boiling purified water, adding the smashed rice into the purified water and boiling for 1 h to obtain liquid A, wherein the weight ratio of the rice to the purified water is 1:30; step II, taking a clean soil jar, pouring the liquid A which is cooled to 45 DEG C into the jar, injecting a natural leavening agent into the jar and sealing, fermenting for about 10 days under the temperature condition of 35 DEG C to obtain liquid B, wherein the weight ratio of the natural leavening agent to the liquid A is 1:2; step III, adding Hmong tail alcohol into the liquid B, continuously fermenting for 3 days to obtain liquid C, taking a supernatant of the liquid C to obtain Hmong white sour soup.

Owner:KAILI TIANYUAN FOOD DEV CO LTD

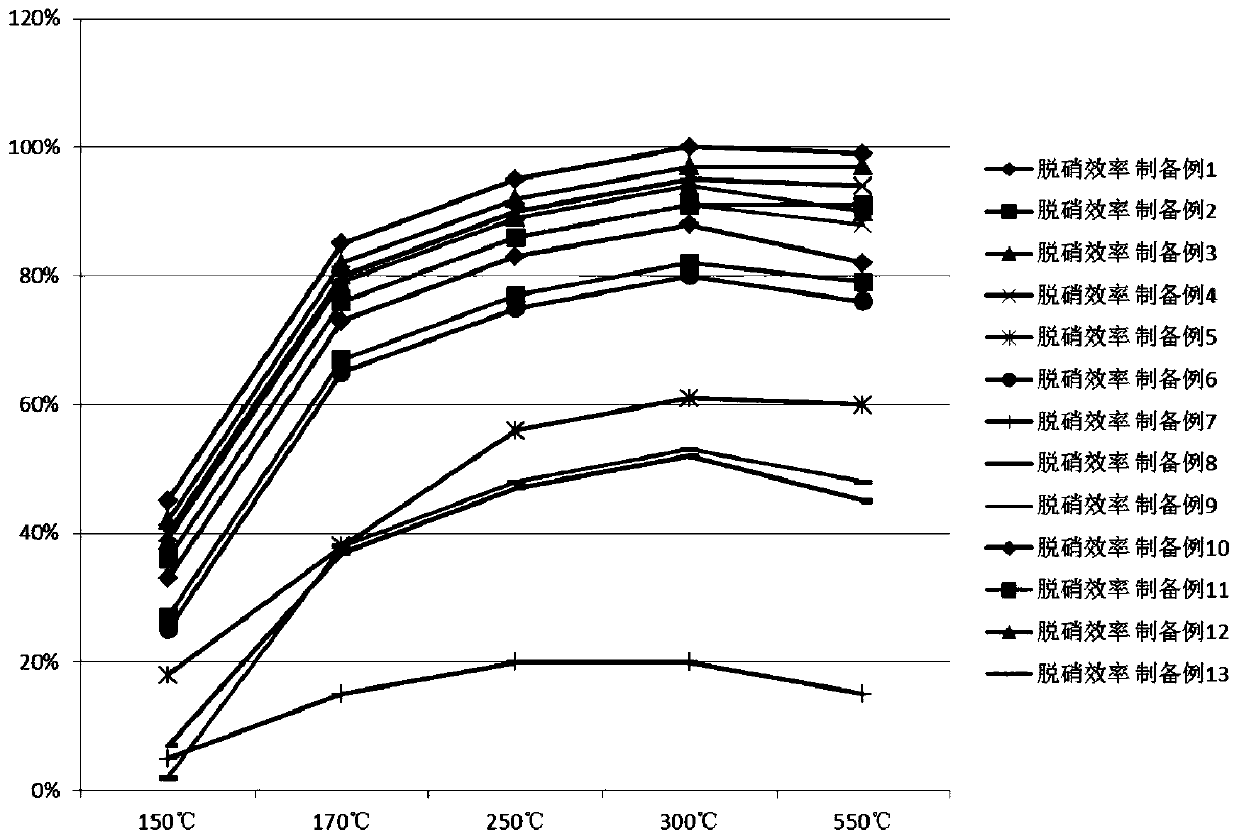

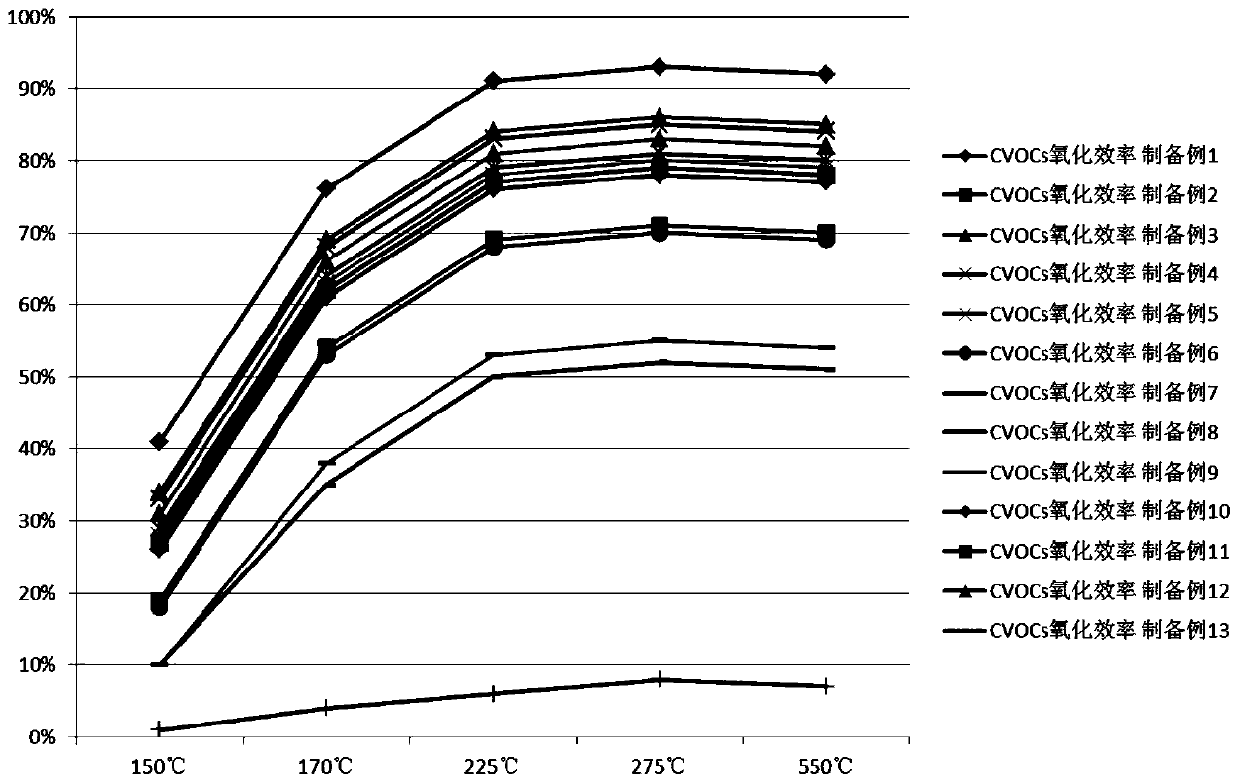

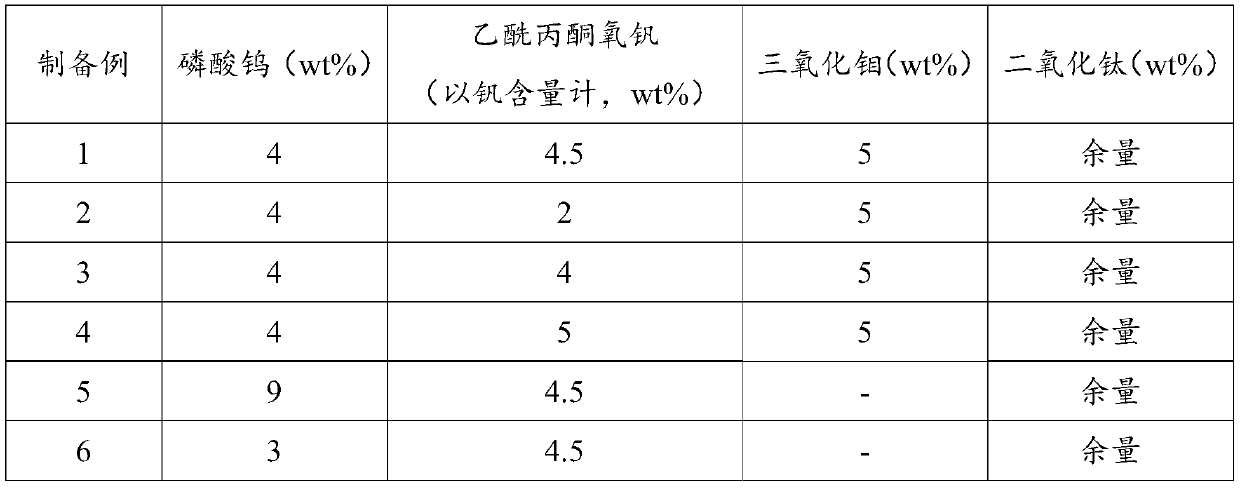

SCR catalyst powder as well as preparation method and application thereof

ActiveCN109731593AHigh catalytic activityIncrease reaction ratePhysical/chemical process catalystsDispersed particle separationPhosphateHigh activity

The invention discloses SCR catalyst powder as well as a preparation method and application thereof. The catalyst adopts tungsten phosphate serving as a tungsten source precursor, vanadium acetylacetonate serving as a vanadium source precursor and TiO2 and / or MoO3 serving as a carrier as raw materials, wherein the vanadium content in the catalyst powder is not less than 2 percent by weight. The catalyst powder has high activity while maintaining dioxin oxidation degradation and SCR reaction, and has a wide active temperature window with a temperature span of 170 to 550 DEG C.

Owner:SHANDONG UNIV

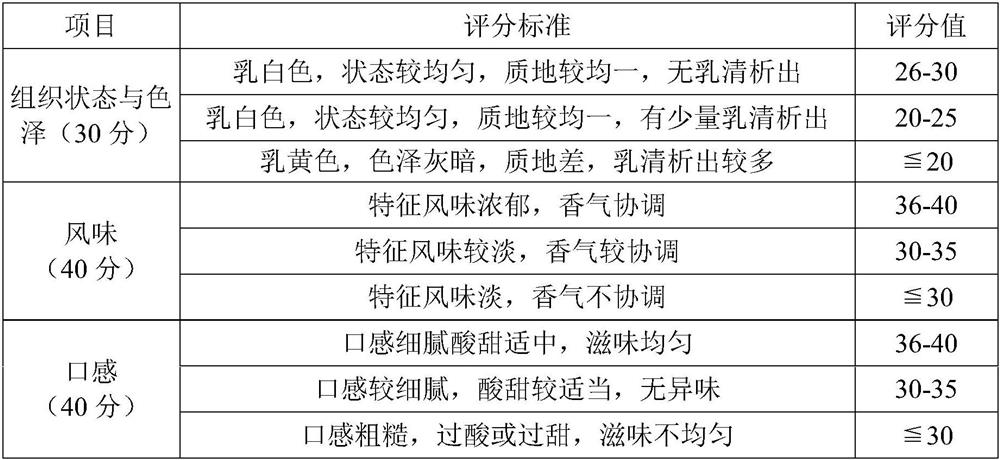

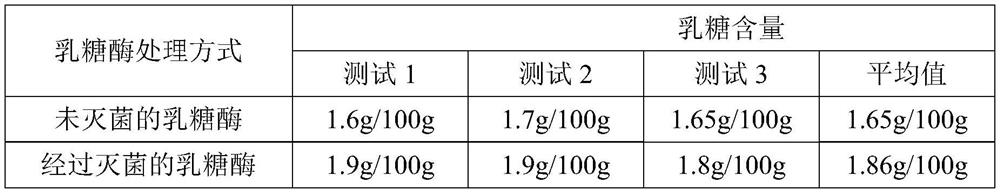

Low-fat and low-lactose compound yogurt and preparation method thereof

PendingCN113575680AMeet nutritional needsMeet market development trendsMilk preparationMilk preservationBacteriocinMouthfeel

The invention provides low-fat and low-lactose compound yogurt and a preparation method thereof. The preparation method comprises the following steps: carrying out enzymolysis by adopting unsterilized lactase after sterilization and before fermentation, and in terms of 100% of the total weight of yoghourt raw materials, the yoghourt raw materials comprise 0.04-0.06% of an acidity regulator and 0.0005-0.0015% of bacteriocin, and the acidity regulator and the bacteriocin are used for inhibiting infectious microbes in the lactase. The invention also provides the low-fat and low-lactose compound yoghourt which is prepared by the preparation method. The preparation method provided by the invention can effectively reduce the lactose content of the yoghurt product and avoid deterioration of the product, and the prepared low-fat low-lactose composite yoghurt has relatively good stability and good flavor and taste.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

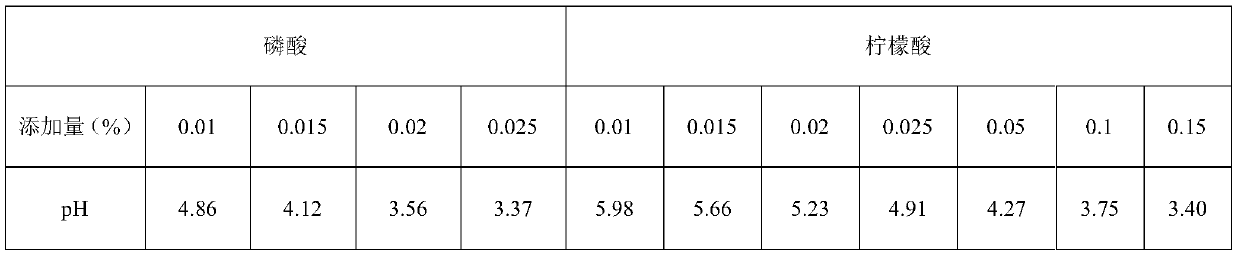

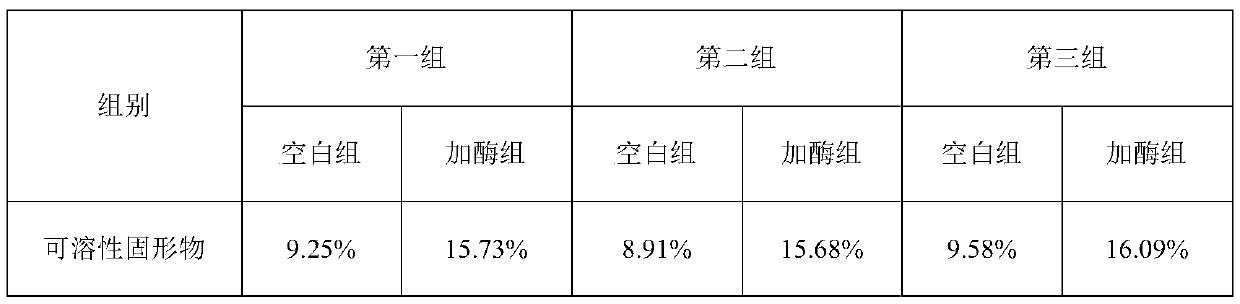

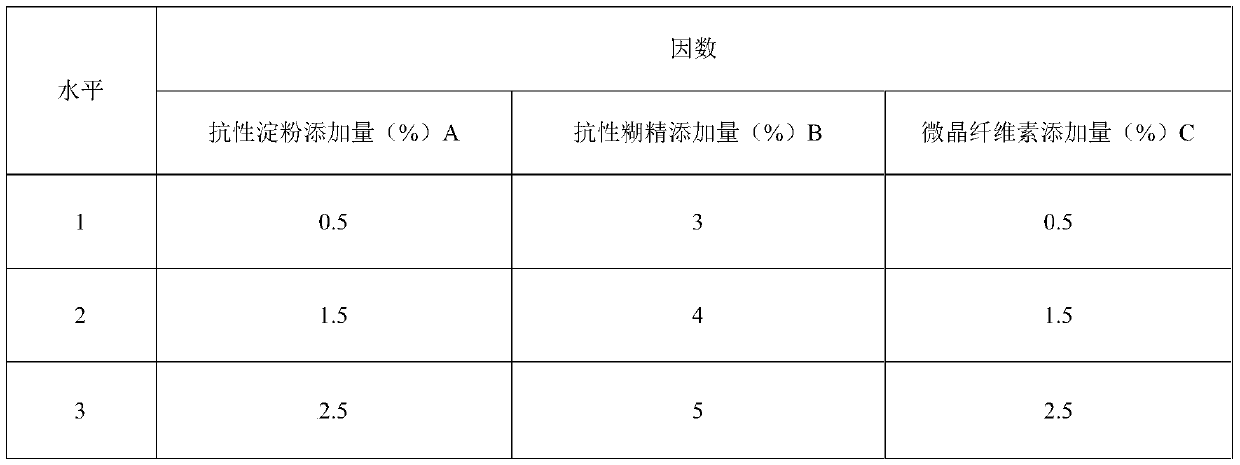

Preparation method of whole black carrot powder rich in anthocyanin and application of prepared whole black carrot powder in food

InactiveCN110101045AIncrease acidityAcidity guaranteeDough treatmentBakery productsFlavorAdditive ingredient

The invention discloses a preparation method of whole black carrot powder rich in anthocyanidin and application of the prepared whole black carrot powder in food. In the preparation process, the method comprises the following steps of cleaning, freezing and thawing, crushing, color protecting, ball milling, homogenization, enzymolysis, sterilization, spray drying and the like, and finally the whole black carrot powder can be obtained. The preparation process is simple, the production cost is low, the consumed time is short, the prepared whole black carrot powder retains the nutritional ingredients and flavor to a great extent, the content of anthocyanin is increased to the greatest extent, soluble solid matter is increased, and finally the homogeneity of the product is guaranteed; the powder is used for in baked food or frozen food or instant drinks, the taste can be enriched, the color and luster are added, and the powder has very high nutritional value.

Owner:湖北紫鑫生物科技有限公司

A kind of method utilizing wet process phosphoric acid to prepare ferrous phosphate

ActiveCN112794299BReduce generationPrevent compromising purityPhosphorus compoundsO-Phosphoric AcidPhosphate

The invention relates to a method for preparing ferrous phosphate by using wet-process phosphoric acid, comprising the following steps: under the condition of 40-100°C, adding a basic magnesium compound to the phosphoric acid solution to adjust the pH to 3-6, and filtering to obtain a filter residue and a filtrate One; add ferrous sulfate in filtrate one and pass into carbon dioxide, add the pH of alkaline magnesium compound to adjust the solution to be 3-5, obtain product ferrous phosphate hydrate and filtrate two; The pressure of carbon dioxide above described filtrate one is 0.01 ‑1Mpa; add a basic magnesium compound to the filtrate two until the pH value of the solution is greater than 6, solid-liquid separation obtains the filter residue three and the filtrate three, and when the content of aluminum on a dry basis in the filter residue three is lower than 2%, the filter residue is used Substitute or partially replace the basic magnesium compound in step 2. Based on the method for preparing ferrous phosphate by wet-process phosphoric acid of the present invention, ferrous phosphate with relatively high purity can be prepared, and the preparation process is short, and the operation is simple, which reduces the cost of preparing ferrous phosphate by wet-process phosphoric acid.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

Method for preventing wine tartar crystallization on basis of ultrasonic technology

ActiveCN104560588AGuaranteed acidityKeep the aromaAlcoholic beverage preparationEconomic benefitsTartrate

The invention discloses a method for preventing wine tartar crystallization on the basis of an ultrasonic technology and relates to the technical field of wind making. The method comprises the following steps: ultrasonic treatment: conducting ultrasonic treatment on green wine under certain ultrasonic conditions; (2) adding a wine tartrate stabilizer: adding the emulsified wine tartrate stabilizer into the wine subjected to ultrasonic treatment, and mixing the wine tartrate stabilizer and the wine uniformly. The method provided by the invention can prevent tartar crystallization during storage of the wine, keeps the original taste, physical and chemical properties, fragrance and other quality indexes of the wine, and guarantees the interior quality of the wine. Meanwhile, the method simplifies the production technology of the wine, reduces the production cost of the wine, avoids resource waste and is conductive to increasing the economic benefits of wine production.

Owner:山东康来农业科技发展有限公司

Power Battery

ActiveCN104332633BImprove corrosion resistanceHigh strengthElectrode carriers/collectorsPower batteryPower flow

The invention discloses a ternary non-aggregated power battery. The ternary non-aggregated power battery comprises positive and negative pole plates composed of plate grids and active substances, wherein the active substances are composed of lead powder and sulfuric acid; each plate grid is a ternary non-aggregated alloy plate grid; a positive pole plate grid is prepared from the following components in parts by weight: 0.02%-0.03% of Ag, 0.05%-0.06% of Ti, 0.9%-1.5% of Sn, 0.06%-0.08% of Ca and the balance of Pb; and a negative pole plate grid is prepared from the following components in parts by weight: 0.08%-0.09% of Ca, 0.02%-0.05% of Al, 1.0%-1.6% of Sn and the balance of Pb. According to the ternary non-aggregated power battery, Sn, Al and Ti elements are added into the plate grids and an alloy interface presents an amorphous-state polymer; the resistance of a resistance layer is obviously reduced; the circulating service life of the battery is prolonged and large-current charging and discharging performances of the battery are improved; and the corrosion resistance of the plate grids in sulfuric acid is improved and the service life of the battery is greatly prolonged.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU NEW ENERGY

A kind of fast fermentation method of green mustard

ActiveCN104770696BIncrease concentrationIncrease growth factorClimate change adaptationFood scienceSalt waterMyrosinase

The invention discloses a fast fermentation method of green leaf mustard. The fast fermentation method comprises three procedures including pretreatment, salting and sealing of a pool, wherein the salting procedure also comprises four substeps of salting lower green leaf mustard, adding auxiliary materials and aged salt water, crudely extracting myrosase and adding lactic acid bacteria. The fast fermentation method disclosed by the invention has the advantages that due to addition of glucose, the concentration of substrates can be increased, the growth factors of the lactic acid bacteria can be increased and the growth of the lactic acid bacteria can be accelerated; the green leaf mustard contains myrosinase for inhibiting the growth of the lactic acid bacteria, and due to addition of the myrosase, the myrosinase can be damaged and the fast fermentation of the green leaf mustard can be promoted; since the naturally-fermented lactic acid bacteria is insufficient, the acidity of the salted green leaf mustard can be increased. The fast fermentation method disclosed by the invention has the characteristics that the fermentation of the lactic acid bacteria can be accelerated, the acidity of the leaf mustard can be increased and the salting and fermentation time for the leaf mustard can be shortened.

Owner:四川省味聚特食品有限公司

How to Plant Apple Trees on a Hillside

ActiveCN105248231BHigh sweetnessPrevent quality degradationBio-organic fraction processingExcrement fertilisersApple maggotApple peel

The invention discloses a method of planting apple trees on a mountain slope. The method comprises the first step of preparation before planting, the second step of planting, wherein apple tree seedlings are sequentially planted in different cement frame sets from bottom to top along the mountain slope according to successively increasing heights, and the third step of fertilization, wherein one month after the apple trees are planted, a plurality of spherical gelatin sponges are placed nearby roots of each apple tree seedling. According to the method, the mountain slope with the gradient between 40 degrees and 50 degrees and the orientation to the south is selected, the apple tree seedlings with different heights are sequentially planted in different cement frame sets from bottom to top along the mountain slope according to successively increasing heights, the apple tree seedlings are distributed in a step shape, it is guaranteed that all the apple tree seedlings can enjoy sunlight within the maximum range, sunlight exposure is more sufficient, the sweetness of apples is improved, and the problem that the quality of apples is lowered because leaves on the lower sides of the apple trees cannot be exposed to sunlight and illumination is uneven when the apple trees are planted on flat land is avoided; moreover, when the apple trees are planted on the mountain slope, the stability of the mountain slope can also be improved.

Owner:吴堡县丰润现代农业开发有限公司

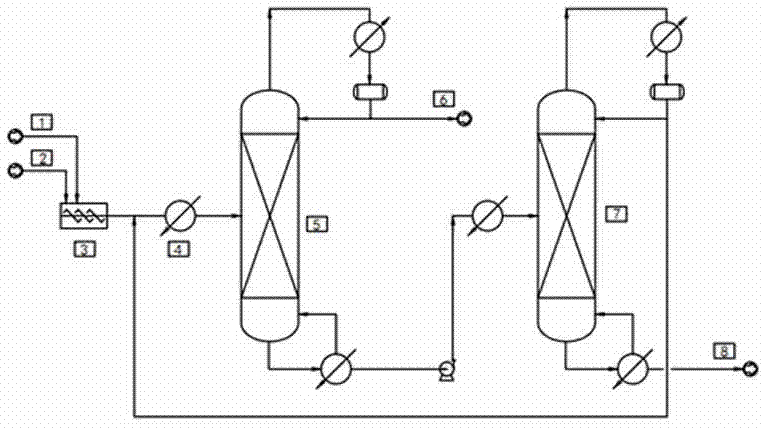

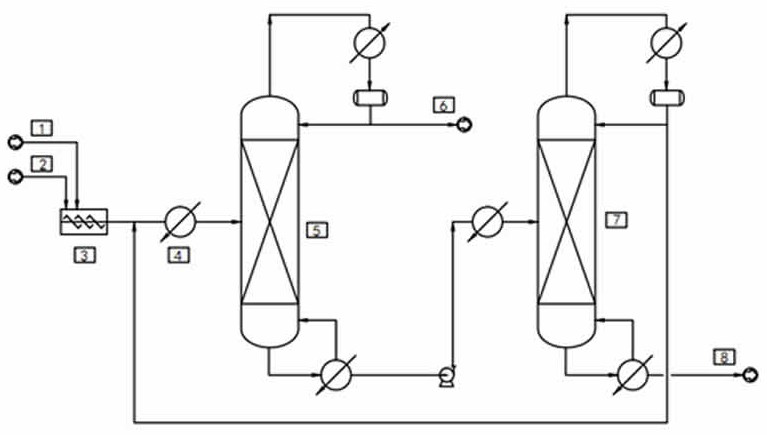

Efficient and energy-saving reaction process for alcohol ether solvent and reaction system of reaction process

ActiveCN107445824AIncrease profitReduce the ratioPreparation by ester-hydroxy reactionChemical industryChemistryChemical production

The invention discloses an efficient and energy-saving reaction process for an alcohol ether solvent and a reaction system of the reaction process, and relates to the technical field of chemical production equipment. The reaction process comprises the following steps: (1) respectively feeding an alcohol ether solvent and ethyl acetate into a static mixer from a glycol ether or propylene glycol ether pump and an ethyl acetate feeding pump according to a ratio of (1:1)-(1:3), uniformly mixing, feeding into a reactive distillation column, and implementing a reaction, wherein the reaction pressure is 0.1-3MPa, and the reaction temperature is 90-110 DEG C; (2) pressurizing, removing excessive ethyl acetate and ethanol generated from the reaction from the top of the reactive distillation column, and recycling the ethyl acetate as first ester into an ethyl acetate esterification system; (3) feeding an alcohol ether ester solvent generated from the reaction and an unreacted alcohol ether solvent into a light component removal tower, and removing the unreacted alcohol ether solvent, thereby obtaining a finished product of the alcohol ether ester solvent from the bottom of the light component removal tower. The reaction process is high in conversion rate, low in cost and convenient in separation, and the utilization rate of ethyl acetate is increased.

Owner:谦信化工集团有限公司 +1

A high-efficiency and energy-saving reaction process and reaction system for alcohol ether ester solvents

ActiveCN107445824BIncrease profitReduce the ratioPreparation by ester-hydroxy reactionChemical industryAlcohol ethylReaction temperature

The invention discloses an efficient and energy-saving reaction process for an alcohol ether solvent and a reaction system of the reaction process, and relates to the technical field of chemical production equipment. The reaction process comprises the following steps: (1) respectively feeding an alcohol ether solvent and ethyl acetate into a static mixer from a glycol ether or propylene glycol ether pump and an ethyl acetate feeding pump according to a ratio of (1:1)-(1:3), uniformly mixing, feeding into a reactive distillation column, and implementing a reaction, wherein the reaction pressure is 0.1-3MPa, and the reaction temperature is 90-110 DEG C; (2) pressurizing, removing excessive ethyl acetate and ethanol generated from the reaction from the top of the reactive distillation column, and recycling the ethyl acetate as first ester into an ethyl acetate esterification system; (3) feeding an alcohol ether ester solvent generated from the reaction and an unreacted alcohol ether solvent into a light component removal tower, and removing the unreacted alcohol ether solvent, thereby obtaining a finished product of the alcohol ether ester solvent from the bottom of the light component removal tower. The reaction process is high in conversion rate, low in cost and convenient in separation, and the utilization rate of ethyl acetate is increased.

Owner:谦信化工集团有限公司 +1

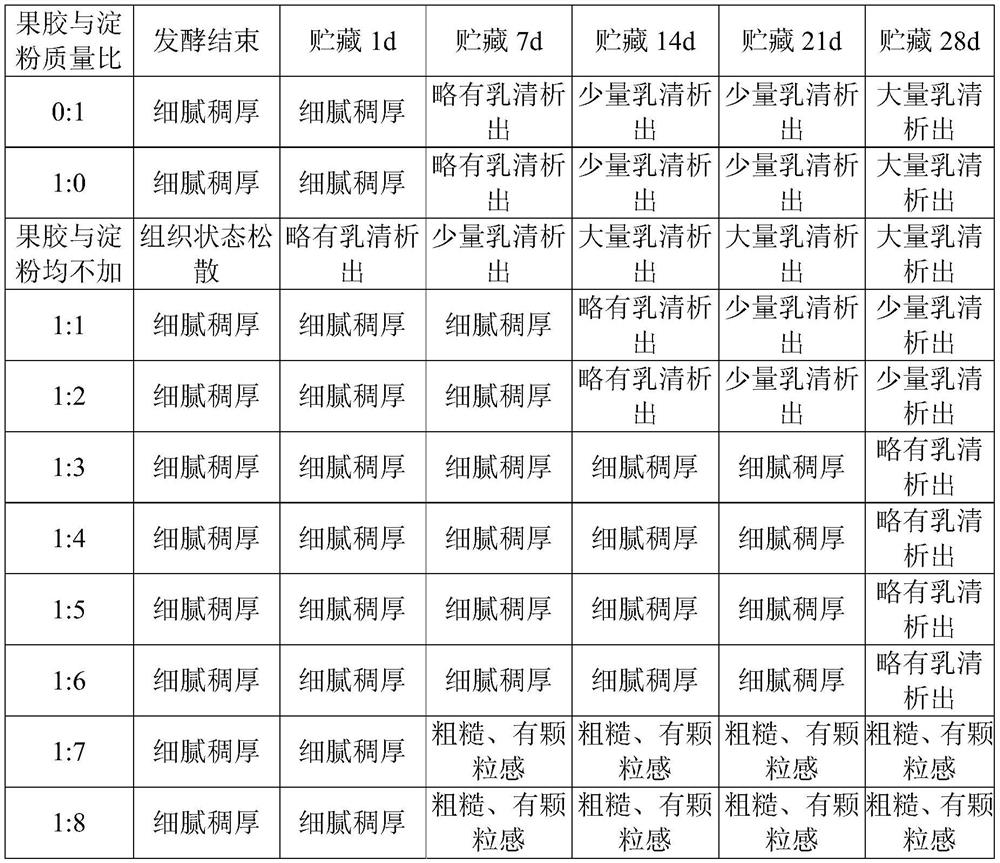

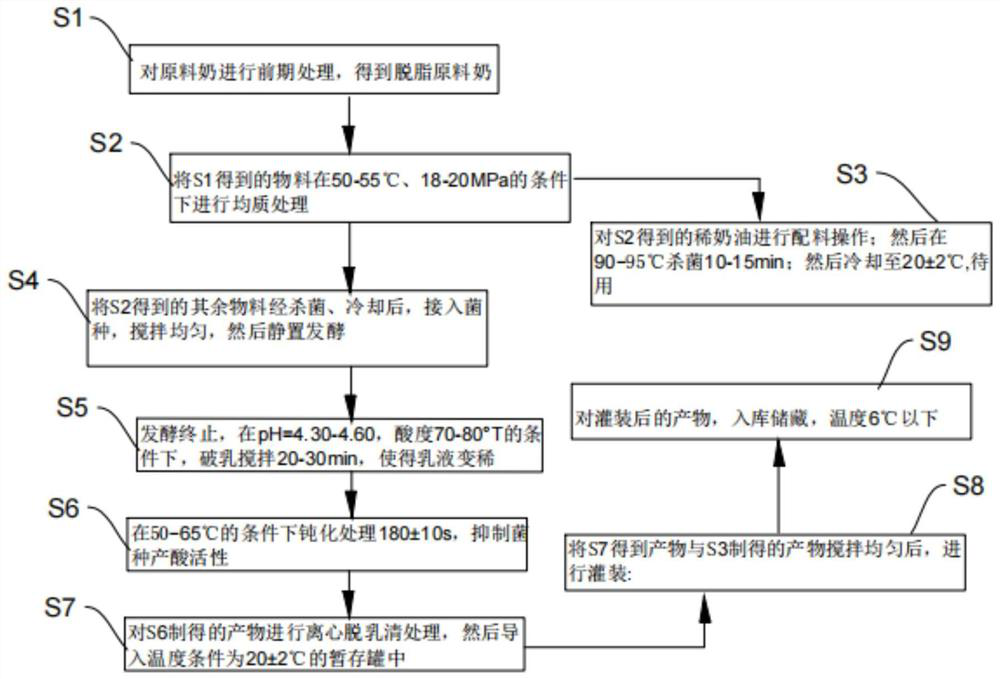

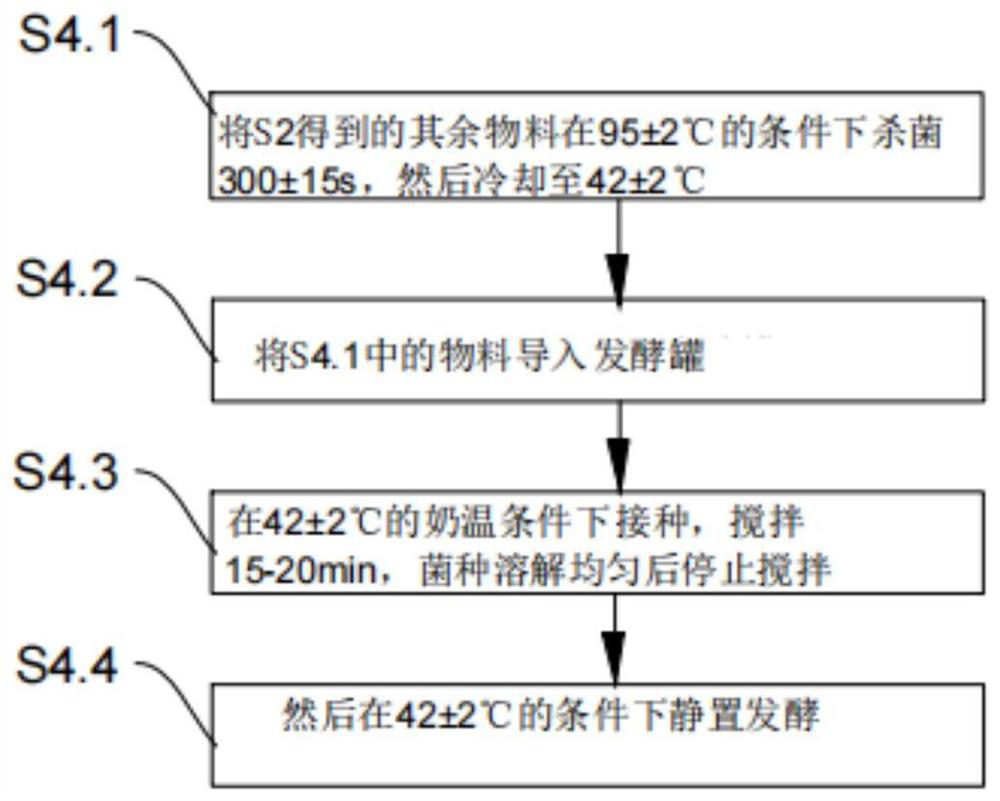

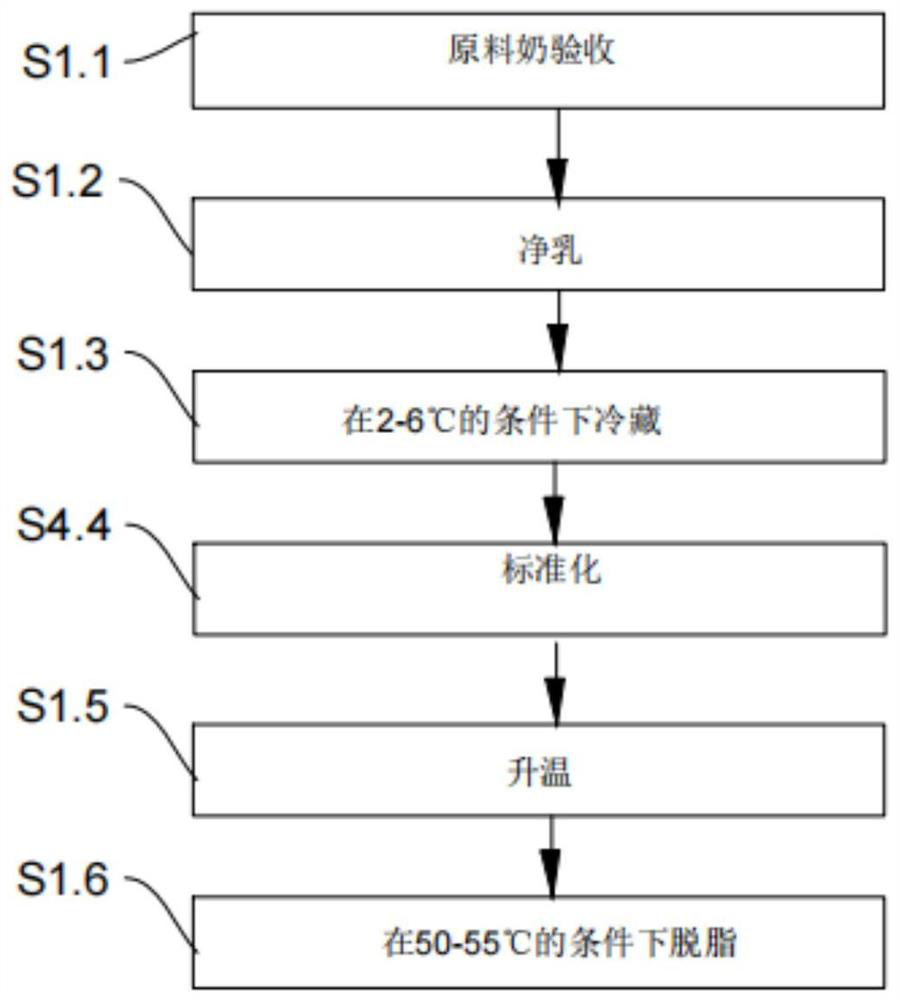

Greek yogurt and preparation method thereof

The present invention provides Greek yogurt and a preparation method thereof, and belongs to the technical field of food engineering, and the preparation method comprises the following steps: step 1, raw material milk is subjected to pretreatment to obtain degreased raw material milk; s2, carrying out homogenization treatment on the material obtained in the step S1; s3, blending the single cream obtained in the step S2; then sterilizing again; then cooling; s4, sterilizing and cooling other materials obtained in S2, inoculating strains, uniformly stirring, and then standing for fermentation; s5, stopping fermentation, demulsifying and stirring to dilute the emulsion; s6, passivating treatment is conducted for 60-200 s under the condition of 50-65 DEG C, and the acid production activity of the strains is inhibited; s7, carrying out centrifugal whey removal treatment on the product prepared in the step S6, and then introducing the product into a temporary storage tank; and S8, uniformly stirring the product obtained in the step S7 and the product prepared in the step 3, and filling. According to the preparation method of the Greek yoghurt provided by the invention, the taste of the final product is ensured through the combination of a single cream melting process and a passivation process.

Owner:北京乐纯悠品食品科技有限公司

How to Grow Orange Trees on a Hillside

ActiveCN105453976BHigh sweetnessPrevent quality degradationExcrement fertilisersAmmonium nitrate fertilisersOrange TreeSweetness

The invention provides a method for planting orange trees on a mountain slope. The method comprises the following steps of (1) preparation before plantation, (2) plantation, including planting orange tree seedlings in different cement frameworks along the mountain slope from the bottom to the top according to an order of orderly increased height, and (3) fertilizer application, including placing a plurality of spherical gelatine sponge surrounding a root of each orange tree. The mountain slope is sunward with gradient from 37 to 45 degrees; the orange tree seedlings with various heights are orderly planted in different cement frameworks from the bottom to the top along the mountain slope according to the order of increased height; the orange tree seedlings can be distributed in a step shape and sunlight is ensured for orange tree seedlings to the largest extent; with adquate sunniness, orange sweetness can be increased; a problem of low quality of oranges due to uneven sunlight when orange trees are planted on the flat land and leaves of the lower side of the orange trees cannot be illuminated; and mountain slope stability can be enhanced with the orange trees planted on the mountain slope.

Owner:重庆橙杨生态农业有限公司

A method for efficiently utilizing high-alumina coal gangue

ActiveCN108975367BSolve operational problemsReasonable settingAluminium compoundsSilicaAluminium hydroxideSludge

Owner:KUNMING UNIV OF SCI & TECH +1

A method for preventing crystallization of wine tartar based on ultrasonic technology

ActiveCN104560588BGuaranteed acidityKeep the aromaAlcoholic beverage preparationEconomic benefitsTartrate

Owner:山东康来农业科技发展有限公司

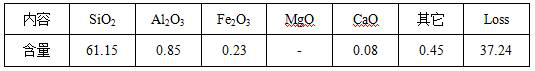

Method for Improving Decomposition Efficiency of Rare Earth Minerals and Sulfuric Acid

ActiveCN111394571BIncrease the speed of diffusionReduce consumptionProcess efficiency improvementIron sulfateHydrometallurgy

The invention relates to a method for improving the decomposition efficiency of rare earth minerals and sulfuric acid, belonging to the field of hydrometallurgy. Including mixing rare earth concentrate with concentrated sulfuric acid and iron powder for segmental roasting, adding a certain amount of water to the solidified minerals during the low-temperature roasting process, optimizing the solid-liquid-gas reaction system, and improving the diffusion of sulfuric acid in the reaction process Speed, reduce sulfuric acid consumption, increase rare earth decomposition rate. During the high-temperature roasting process, the high-efficiency decomposition of excess sulfuric acid and the formation of iron phosphate and thorium pyrophosphate mainly fix radioactivity and phosphorus resources into the slag. The two-stage roasting simplifies the components of the tail gas, which facilitates the subsequent tail gas treatment, reduces the cost of tail gas treatment, and reduces environmental pollution.

Owner:BAOTOU RES INST OF RARE EARTHS +1

How to Grow Peach Trees on a Hillside

ActiveCN105359913BHigh sweetnessPrevent quality degradationBio-organic fraction processingExcrement fertilisersGelatin spongeSweetness

The invention provides a peach tree planting method on a hillside. The method comprises the following steps of (1) preparing before planting, (2) planting, including planting peach tree seedlings in various cement framework groups on a hillside from the bottom to the top according to a height gradual increase order, and (3) applying fertilizer, wherein in the fertilizer applying step, one month after plantation, a plurality spherical gelatin sponge are placed around a root of each peach tree seedling; a sunward hillside with the gradient of 37 to 45 degrees is selected; peach tree seedlings are planted in various cement framework groups on a hillside from the bottom to the top according to the height gradual increase order; the peach tree seedlings are distributed in a step shape to ensure the peach tree seedlings to enjoy the sunshine to the largest extent; with thorough sunniness, peach sweetness can be enhanced; a problem of peach quality decrease due to uneven sunniness acquired by peach trees planted on a flat land and lack of sunniness to lower sides of the peach trees can be solved; and hillside stability can be improved when the peach trees are planted on the hillside.

Owner:哈威光电科技(苏州)有限公司

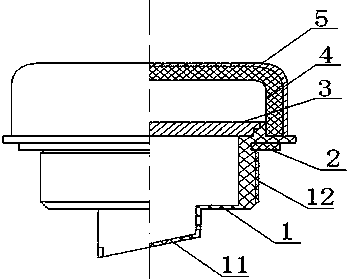

Anti-acid mist type battery filling cap

InactiveCN103972434AReduce combustible gas contentGuaranteed acidityCell component detailsCell lids/coversDecompositionElectrolyte

The invention discloses an anti-acid mist type battery filling cap. The battery filling cap comprises a cap body, wherein the cap body is sealed with a battery cap through threads; a labyrinth loop is arranged on the top surface of the cap body; a cap is arranged at the upper part of the cap body, and covers the labyrinth loop; an anti-acid mist piece is arranged in the cap; a reflowing hole is formed in the centre of the labyrinth loop; exhaust holes are formed in the cap. During the use of the storage battery, acid mist brought from the decomposed electrolyte solution passes through the labyrinth loop to form liquid drops to flow back into the storage battery, a small quantity of acid mist which does not form liquid drops is filtered through the anti-acid mist piece, and gas generated by water decomposition is exhausted through the exhaust holes in the cap. Therefore, the content of a combustible gas in the storage battery is reduced, the acid volume in the electrolyte solution of the storage battery can be efficiently guaranteed, and the service life of the storage battery is prolonged.

Owner:TIANNENG GRP JIANGSU SPECIAL POWER SUPPLY

Production method of hydrated terpene glycol and terpineol

ActiveCN106966860BDoes not affect compositionImprove general performanceOrganic compound preparationPreparation by OH group eliminationHydration reactionTurpentine

Owner:FUJIAN SENFA BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com