Method for efficiently utilizing high-aluminum gangue

A high-alumina coal gangue, high-efficiency technology, applied in chemical instruments and methods, aluminum compounds, silicon dioxide, etc., can solve the problems of unseen reports, achieve high added value, simple extraction process, and eliminate environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

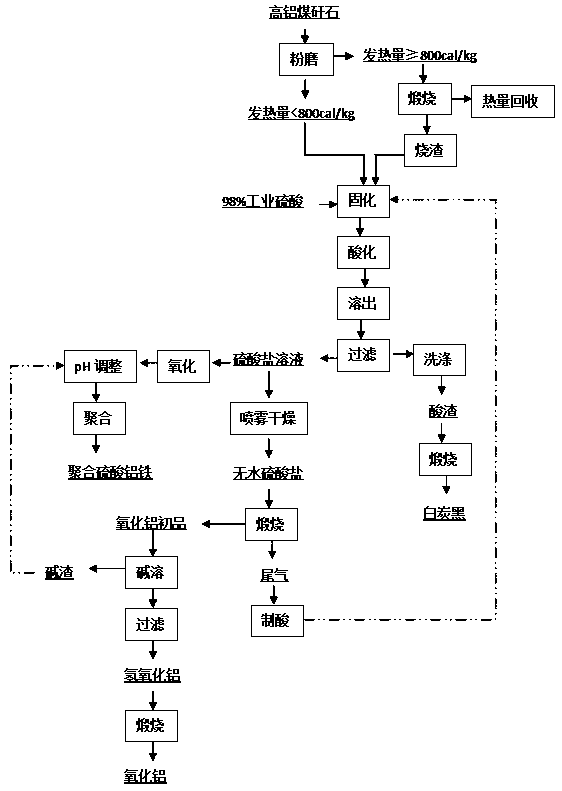

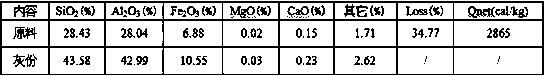

[0032] (1) if figure 1 As shown, the analysis results of coal gangue raw materials and ash content are shown in Table 1.1. It can be seen from the table that this coal gangue has a relatively high calorific value, and the heat should be recovered before slag utilization;

[0033] Table 1.1 Coal gangue raw material and ash analysis

[0034]

[0035] (2) Dried the coal gangue and pulverized it, and ground it to a sieve residue of 9.98% through an 80-mesh sieve, and used a circulating fluidized bed to recover heat to obtain slag;

[0036] (3) Add industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.2 to gangue, and solidify at 50°C;

[0037] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.2, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidification kiln for acidification reaction. Th...

Embodiment 2

[0044] (1) The analysis results of coal gangue raw materials and ash content are shown in Table 2.1. It can be seen from the table that the low-level calorific value of this coal gangue is 820cla / kg, which meets the heat recovery requirements. The heat should be recovered before slag utilization;

[0045] Table 2.1 Coal gangue raw material and ash analysis

[0046]

[0047] (2) Dried the coal gangue and pulverized it, and ground it to a sieve residue of 6.23% through an 80-mesh sieve, and used a circulating fluidized bed to recover heat to obtain slag;

[0048] (3) adding industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.1 to gangue, and solidifying at room temperature;

[0049] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.1, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidifi...

Embodiment 3

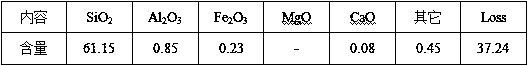

[0056] (1) The analysis results of coal gangue raw materials and ash content are shown in Table 3.1. It can be seen from the table that the low-level calorific value of this coal gangue is 452cla / kg, which does not meet the heat recovery requirements. The coal gangue is directly used after drying, crushing and grinding;

[0057] Table 3.1 Coal gangue raw material and ash analysis

[0058]

[0059] (2) Grinding the coal gangue in step (1) to a sieve residue of 4.56% through a 100-mesh sieve;

[0060] (3) Add industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.2 to gangue, and solidify at 35°C;

[0061] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.15, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidification kiln for acidification reaction. The heating temperature at the inlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com