Mobile heavy-object loading and unloading platform

A loading and unloading platform, mobile technology, applied in the field of power transmission and transformation test, can solve the problems of poor passability, low chassis of the flatbed cart, large drop, etc., and achieve the effect of improving the passing performance, increasing the width and saving the handling personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

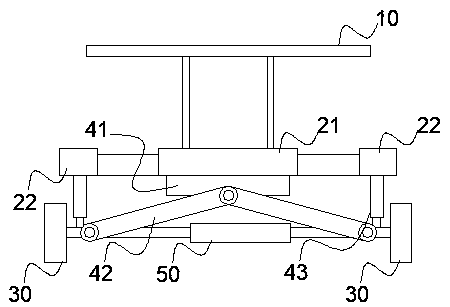

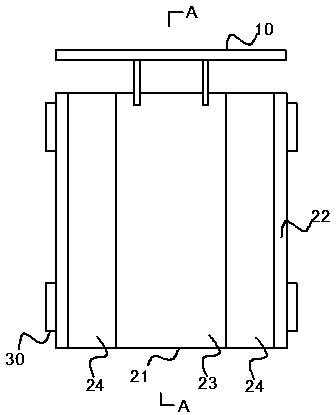

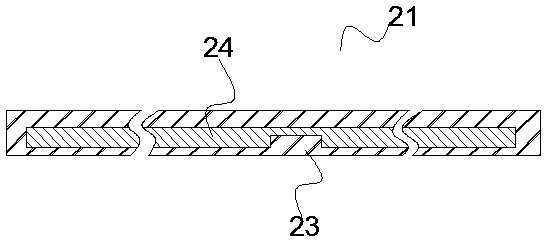

[0029] Such as figure 1 , 2 , 3, this embodiment is a mobile heavy loading and unloading platform, hereinafter referred to as the platform, with adjustable height and width, which includes an adjustment chassis for providing wheeled movement functions, fixed on or integrally formed on the adjustment The telescopic frame on the chassis and the locking mechanism 50 for fixing the width of the telescopic frame, the handle 10 is used to push it to move, and is used to install the operating mechanism or operation panel related to this platform. These operating mechanisms or operation panels are used to set Or adjust and adjust the chassis, telescopic frame or locking mechanism 50 .

[0030] In this embodiment, the adjustment chassis includes a support beam 41, a wheel 30, and an independent suspension connecting the support beam 41 and the wheel 30. Specifically, the independent suspension includes a shock absorber 43 and a support link 42, wherein, One end of the shock absorber ...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference between the platform of this embodiment and the first embodiment is that it also includes a belt 74 arranged on the telescopic frame, a driven roller 71 arranged on both sides for fixing the belt, and a tensioner for adjusting the tension of the belt. Tight rollers 72,73. Wherein, the belt 74 is wound on the driven roller 71 and the tension rollers 72, 73, and is arranged around the telescopic skeleton at the same time, the purpose is to provide a slidable upper surface for the telescopic skeleton, in some other embodiments based on this purpose, the belt 74 All or part of it can also be located on or above the telescopic skeleton.

[0036] In this embodiment, the two ends of the driven roller 71 are fixed on the side beam 22, the belt 74 circulates around the side beam 22, the relative position between the first tension roller 72 and the side beam 22 is fixed, and the second tension roller 73 and the relative position of sup...

Embodiment 3

[0040] Such as Figure 5 As shown, the difference between the platform of the present embodiment and the first embodiment is that the locking mechanism 50 between the wheels 30 is not provided, and the shock absorber 43 is changed to the height adjuster 44, and the height adjuster 44 of the shock absorber 43 and the height adjuster 44 The main difference is that the height adjuster 44 should provide a higher-strength mechanical structure so that it can independently bear the component force from the telescopic skeleton and the supporting link, which is enough to make the wheel 30 formed by the supporting link, the telescopic skeleton and the height adjuster 44. The triangle is fixed.

[0041] In this embodiment, the height adjuster 44 uses a hydraulic cylinder, and the height adjustment of the hydraulic cylinder is locked through the oil circuit. After the oil circuit is locked, since the length of the height adjuster 44 and the supporting link 42 will not change, the telescop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com