SCR catalyst powder as well as preparation method and application thereof

An SCR catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of inability to remove CVOCs, limited improvement of denitration efficiency, etc., and achieve excellent denitration and synergistic removal of CVOCs. Active, wide active temperature window, high active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-5

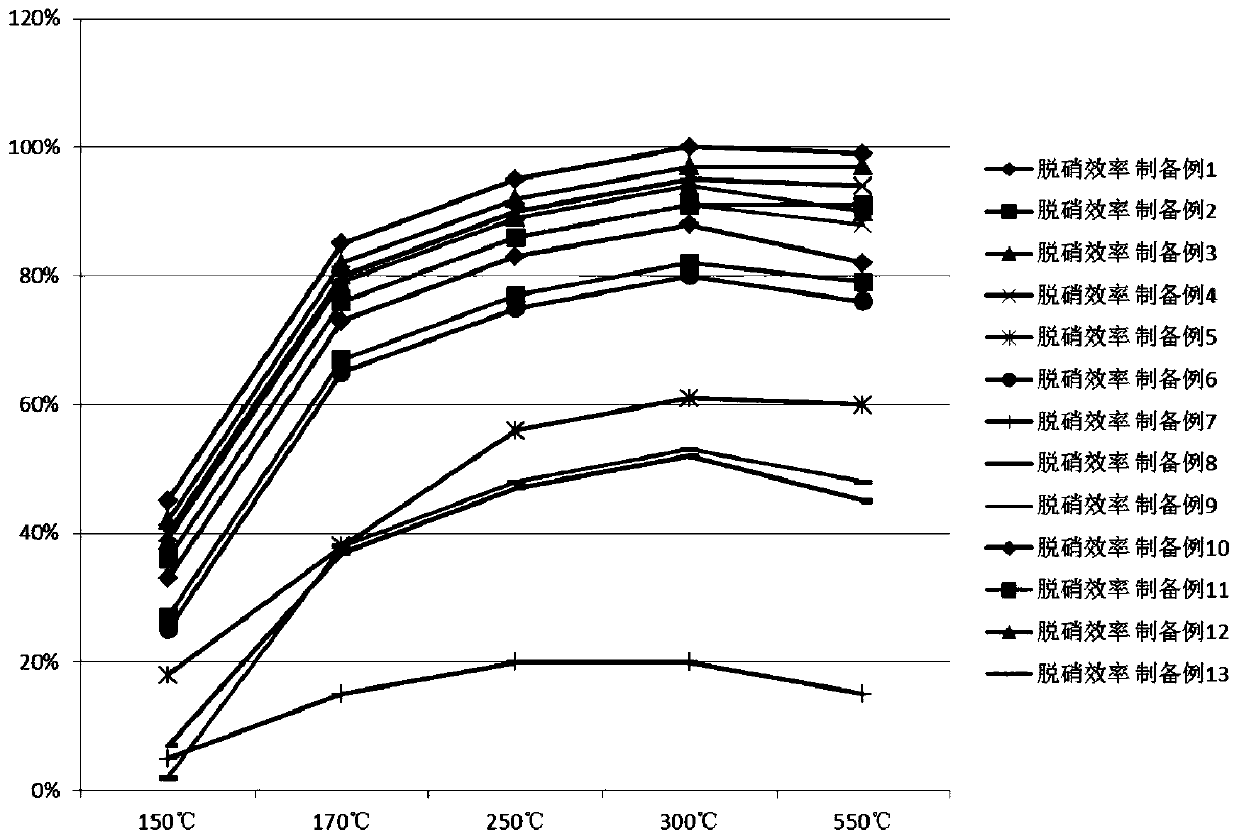

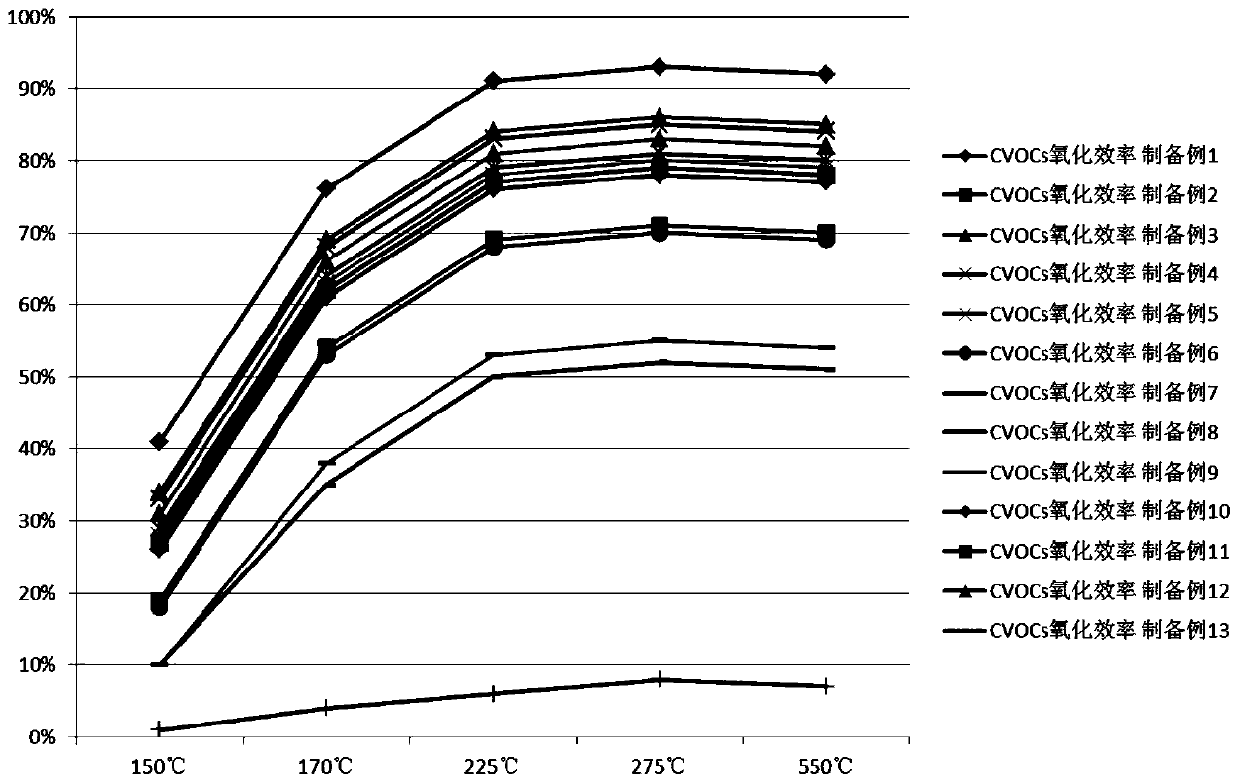

[0049] Preparation Example 1-5 Preparation of SCR Catalyst Powder

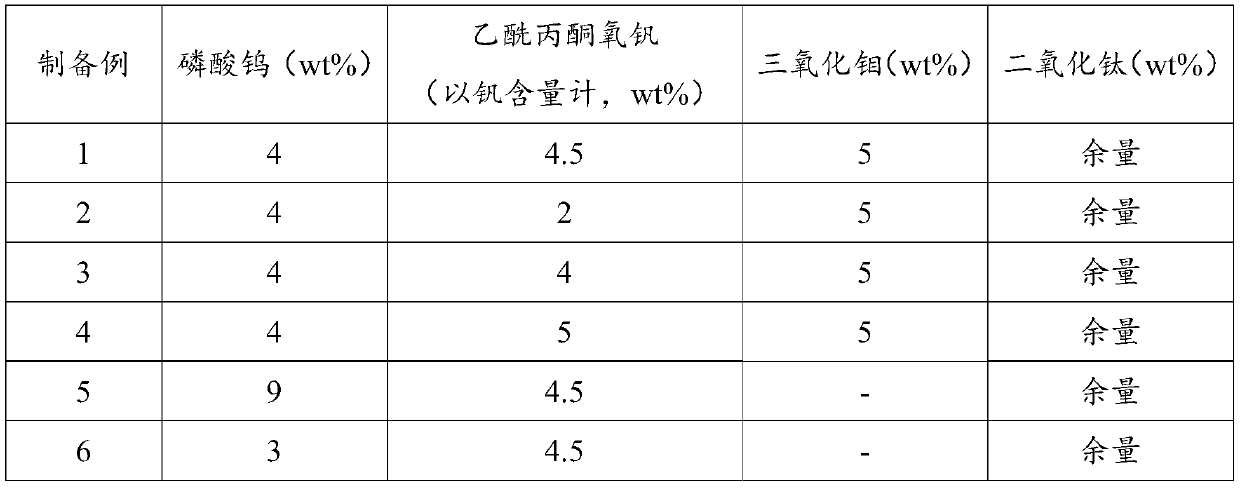

[0050] The raw materials include: tungsten phosphate, vanadyl acetylacetonate, titanium dioxide, and / or molybdenum trioxide, and the content of the raw materials in each preparation example is shown in Table 1 below.

[0051] Measure the raw materials as shown in Table 1 and mix them initially, then add them into a ball mill tank and carry out ball milling for 50 min at a speed of 60 rpm, then the ball milled mixture is dried (110°C, 6h) and roasted in an air atmosphere. Carried out in a muffle furnace, including heating at a rate of 5 °C / min to 95 °C for 5 min; then heating at a rate of 8 °C / min to 280 °C and maintaining for 10 min; then heating at a rate of 8 °C / min to 500 °C keep for 2 hours. After the calcination, it is cooled with the furnace to obtain SCR catalyst powder with a particle size of 40-80 mesh.

[0052] Table 1

[0053]

preparation example 7-11

[0054] Preparation Example 7-11 Preparation of SCR Catalyst Powder

[0055] According to the preparation method and dosage of Preparation Example 1, replace the phosphotungstic acid and / or vanadyl acetylacetonate in Preparation Example 1 with the substances shown in Table 2 to prepare catalyst powder (wherein, the dash "-" in the table represents Same as the tungsten source or vanadium source of Preparation Example 1).

[0056] Table 2

[0057] Preparation example

preparation example 12

[0058] Preparation Example 12 Preparation of SCR Catalyst Powder

[0059] Raw material consumption and composition are the same as Preparation Example 1, adopt the following preparation method:

[0060] Take the raw materials for preliminary mixing, and then put them into the ball mill tank for ball milling, ball milling for 40 minutes, the speed is 30 rpm; the ball milling mixture is taken out and dried at 110°C for 8 hours, and roasted in the air atmosphere: 10°C / min at room temperature to rapidly heat up to 110°C; Slowly raise the temperature at 2°C / min to 300°C; quickly raise the temperature to 500°C at 10°C / min, and keep it at 500°C for 4 hours; finally, cool with the furnace to obtain SCR catalyst powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxidation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com