A method for efficiently utilizing high-alumina coal gangue

A high-alumina coal gangue, high-efficiency technology, applied in chemical instruments and methods, aluminum compounds, silica, etc., can solve problems such as unseen reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

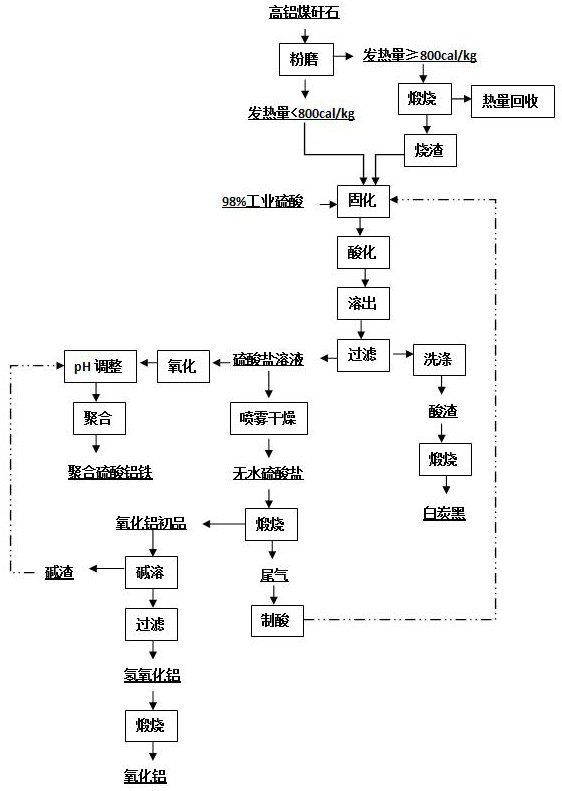

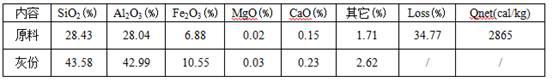

[0032] (1) if figure 1 As shown, the analysis results of coal gangue raw materials and ash content are shown in Table 1.1. It can be seen from the table that this coal gangue has a relatively high calorific value, and the heat should be recovered before slag utilization;

[0033] Table 1.1 Coal gangue raw material and ash analysis

[0034]

[0035] (2) Dried the coal gangue and pulverized it, and ground it to a sieve residue of 9.98% through an 80-mesh sieve, and used a circulating fluidized bed to recover heat to obtain slag;

[0036] (3) Add industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.2 to gangue, and solidify at 50°C;

[0037] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.2, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidification kiln for acidification reaction. Th...

Embodiment 2

[0044] (1) The analysis results of coal gangue raw materials and ash content are shown in Table 2.1. It can be seen from the table that the low-level calorific value of this coal gangue is 820cla / kg, which meets the heat recovery requirements. The heat should be recovered before slag utilization;

[0045] Table 2.1 Coal gangue raw material and ash analysis

[0046]

[0047] (2) Dried the coal gangue and pulverized it, and ground it to a sieve residue of 6.23% through an 80-mesh sieve, and used a circulating fluidized bed to recover heat to obtain slag;

[0048] (3) adding industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.1 to gangue, and solidifying at room temperature;

[0049] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.1, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidifi...

Embodiment 3

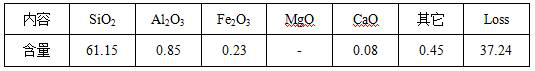

[0056] (1) The analysis results of coal gangue raw materials and ash content are shown in Table 3.1. It can be seen from the table that the low-level calorific value of this coal gangue is 452cla / kg, which does not meet the heat recovery requirements. The coal gangue is directly used after drying, crushing and grinding;

[0057] Table 3.1 Coal gangue raw material and ash analysis

[0058]

[0059] (2) Grinding the coal gangue in step (1) to a sieve residue of 4.56% through a 100-mesh sieve;

[0060] (3) Add industrial sulfuric acid with a mass concentration of 98% to the coal gangue slag of step (2) at a mass ratio of 1:1.2 to gangue, and solidify at 35°C;

[0061] (4) According to the mass ratio of industrial sulfuric acid and slag being 0.15, take out the coal gangue solidified material in step (3) and add 98% industrial sulfuric acid in the form of spray, and transfer it to a vertical acidification kiln for acidification reaction. The heating temperature at the inlet of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com