Low-fat and low-lactose compound yogurt and preparation method thereof

A low-lactose, compound technology, applied in the field of food processing, can solve problems such as rough taste, layering, lack of smoothness and fineness of yogurt, and achieve the effect of avoiding bacterial contamination, good taste and meeting the market development trend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

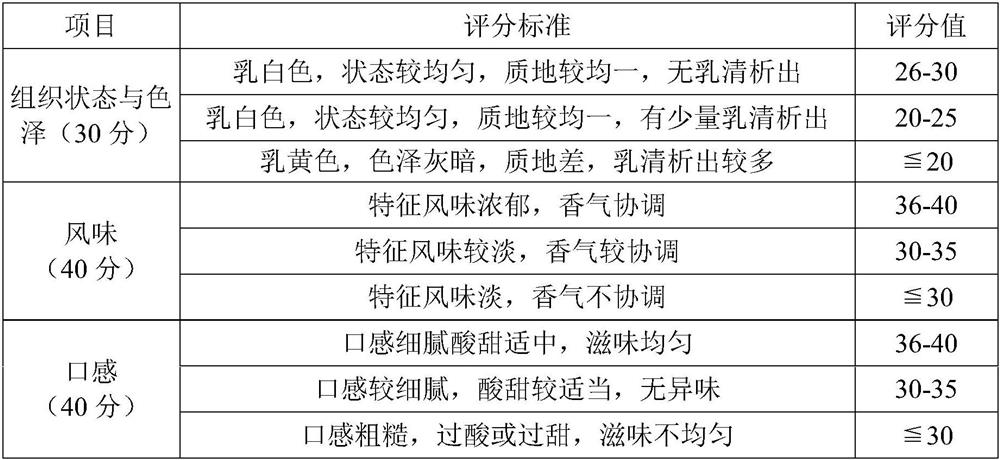

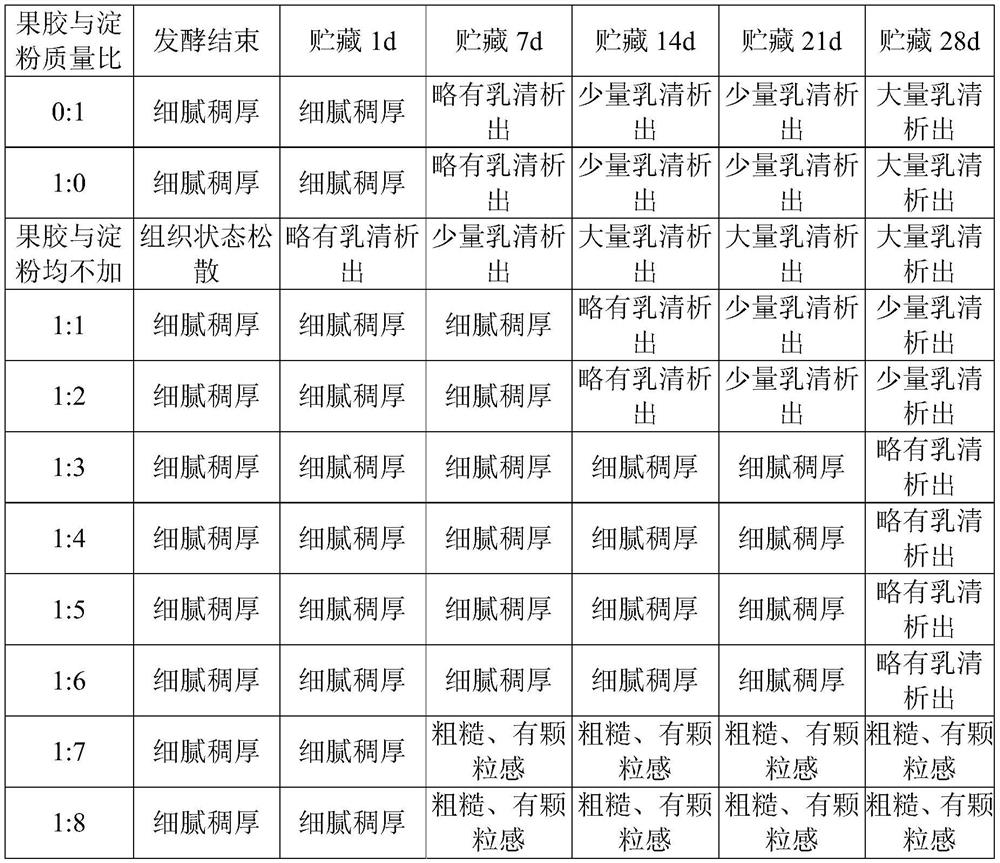

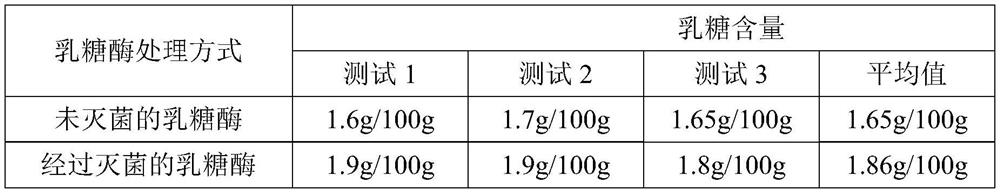

Method used

Image

Examples

Embodiment 1

[0047] This example provides a method for preparing low-fat and low-lactose compound yoghurt. Based on the total weight of yogurt raw materials as 1000g, the used yogurt raw materials of the preparation method are:

[0048] White sugar 20g, concentrated whey protein 5g, compound stabilizer 0.8g (including pectin 0.2g and starch 0.6g), lactic acid 0.5g, bacteriocin 0.01g, unsterilized lactase 700NLU / L, starter 0.02g (including 0.01g of Streptococcus thermophilus and 0.01g of Lactobacillus bulgaricus), the balance of standardized milk.

[0049] The preparation method comprises the following steps:

[0050] 1. Skimming standardization: Use a centrifuge to skim whole milk at 56°C and 0.5 bar to obtain skim milk powder; then hydrate the skim milk powder at 58°C for 30 minutes to obtain standardized milk.

[0051] 2. Degassing of ingredients: add standardized milk to white sugar, concentrated whey protein, stabilizer, lactic acid, and bacteriocin, mix and circulate at 53°C for 45 ...

Embodiment 2

[0056] This example provides a method for preparing low-fat and low-lactose compound yoghurt. Based on the total weight of yogurt raw materials as 1000g, the used yogurt raw materials of the preparation method are:

[0057] White sugar 25g, concentrated whey protein 6g, compound stabilizer 4.8g (including pectin 0.8g and starch 4g), lactic acid 0.5g, bacteriocin 0.01g, unsterilized lactase 800NLU / L, starter 0.02 g (including Streptococcus thermophilus 0.01g and Lactobacillus bulgaricus 0.01g), standardized milk balance.

[0058] The preparation method comprises the following steps:

[0059] 1. Skimming standardization: Use a centrifuge to skim whole milk at 56°C and 0.5 bar to obtain skim milk powder; then hydrate the skim milk powder at 58°C for 30 minutes to obtain standardized milk.

[0060] 2. Degassing of ingredients: add standardized milk to white sugar, concentrated whey protein, stabilizer, lactic acid, and bacteriocin, mix and circulate at 53°C for 45 minutes, and t...

Embodiment 3

[0065] This example provides a method for preparing low-fat and low-lactose compound yoghurt. Based on the total weight of yogurt raw materials as 1000g, the used yogurt raw materials of the preparation method are:

[0066] White sugar 30g, concentrated whey protein 7g, compound stabilizer 6.2g (including pectin 1.2g and starch 5g), lactic acid 0.5g, bacteriocin 0.01g, 900NLU / L unsterilized lactase, starter 0.02 g (including Streptococcus thermophilus 0.01g and Lactobacillus bulgaricus 0.01g), standardized milk balance.

[0067] The preparation method comprises the following steps:

[0068] 1. Skimming standardization: Use a centrifuge to skim whole milk at 56°C and 0.5 bar to obtain skim milk powder; then hydrate the skim milk powder at 58°C for 30 minutes to obtain standardized milk.

[0069] 2. Degassing of ingredients: add standardized milk to white sugar, concentrated whey protein, stabilizer, lactic acid, and bacteriocin, mix and circulate at 53°C for 45 minutes, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com