Method for Improving Decomposition Efficiency of Rare Earth Minerals and Sulfuric Acid

A technology for minerals and rare earths, applied in the field of improving the decomposition efficiency of rare earth minerals and sulfuric acid, can solve the problems of no good treatment method, cumbersome treatment process, large consumption of sulfuric acid, etc. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

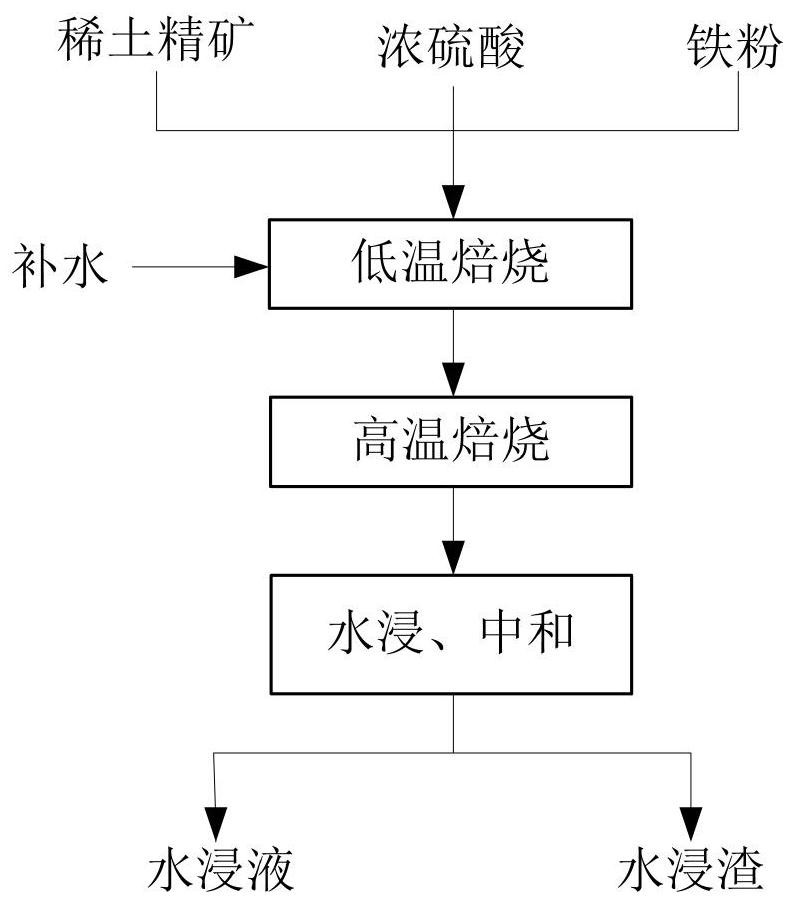

Image

Examples

Embodiment 1

[0025] Mix the mixed rare earth concentrate (REO: 54.22%, P: 8.94%, TFe: 4.97%) and concentrated sulfuric acid according to the weight ratio of 1:1.2, add iron powder, make the total amount of iron and phosphorus in the mineral The molar ratio is 1.2:1, and the low-temperature roasting decomposition is carried out at 200°C. After the concentrate mixed with sulfuric acid is roasted into solid particles, 7% of the mineral weight is added with water to maintain the concentrate in a paste state, and the low-temperature roasting After the end of 90 minutes, directly enter high-temperature calcination, the calcination temperature is 550°C, and the time is 20 minutes. After the calcination, the REO decomposition rate is 98.7%, and the thorium leaching rate is 97.5%.

Embodiment 2

[0027] Add bastnaesite (REO: 65.52%, P: 0.16%, TFe: 2.2%) to a part of apatite, and then mix it with concentrated sulfuric acid at a weight ratio of 1:0.9, and add iron powder to make the total amount of iron The molar ratio of the amount of phosphorus to the phosphorus in the mineral is 1.4:1, and it is roasted and decomposed at 150°C at a low temperature. Paste state, after low-temperature calcination for 100 minutes, directly enter high-temperature calcination at 400°C for 40 minutes. After calcination, the decomposition rate of REO is 98.2%, and the leaching rate of thorium is 96.3%.

Embodiment 3

[0029] Mix mixed rare earth concentrate (REO: 61.66%, P: 4.66%, TFe: 1.14%) and concentrated sulfuric acid at a weight ratio of 1:0.7, add iron powder, make the total amount of iron and phosphorus in the mineral The molar ratio is 1.3:1, and the low-temperature roasting decomposition is carried out at 180°C. After the concentrate mixed with sulfuric acid is roasted into solid particles, 1% of the mineral mass is added with water to maintain the concentrate in a paste state, and the low-temperature roasting After 120 minutes, it directly enters into high-temperature calcination, the calcination temperature is 450°C, and the time is 30 minutes. After the calcination, the REO decomposition rate is 98.3%, and the thorium leaching rate is 96.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com