Method for removing manganous dithionate in pyrolusite slurry leaching solution to prepare saturated manganese sulfate slurry and manganese sulfate

A technology of manganese dithionate and manganese sulfate, which is applied in the direction of manganese sulfate, etc., can solve the problems of increasing the cost of chemicals, increasing the difficulty of purification and impurity removal, and high concentration of sulfuric acid, so as to achieve high resource utilization, cost reduction, and simple process flow easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

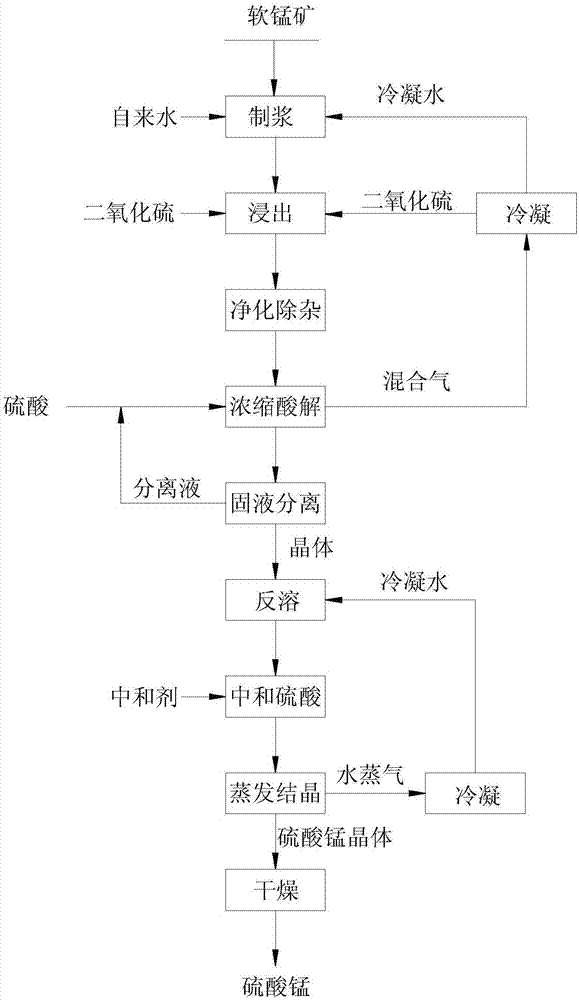

[0043] (1) Pulp preparation: Prepare pyrolusite slurry according to the ratio of pyrolusite and water at a ratio of 1:3.

[0044] (2) Leaching: Utilize sulfur dioxide to react with the pyrolusite slurry obtained in step (1), leach the manganese in the pyrolusite, obtain the slurry containing the pyrolus slag and the leachate, and press filter the slurry to obtain the pyrololus slag and the separating liquid;

[0045] (3) Purification and impurity removal: continuously blow air into the separation liquid obtained in step (2), so that ferrous sulfate is oxidized to ferric sulfate, and calcium hydroxide is added to adjust the pH to 5, so that iron and aluminum in the solution are formed Ferric hydroxide and aluminum hydroxide are precipitated, and after pressure filtration, neutralization slag and separation liquid are obtained; sodium sulfide is added to the separation liquid to cause heavy metal impurities to form sulfide precipitation, and after static precipitation and filtrat...

Embodiment 2

[0053] (1) Pulp preparation: prepare pyrolusite slurry according to the ratio of pyrolusite and water at a ratio of 1:2.

[0054] (2) leaching: utilize sulfur dioxide to react with the pyrolusite slurry gained in step (1), leach the manganese in the pyrolusite, obtain the slurry containing the pyrolus slag and the leachate, and centrifuge the slurry to obtain the pyrololus slag and the separating liquid;

[0055] (3) Purification and impurity removal: add hydrogen peroxide to the separation liquid obtained in step (2) to oxidize ferrous sulfate to ferric sulfate, and add ammonia to adjust the pH to 5.5, so that iron and aluminum in the solution generate ferric hydroxide Precipitate with aluminum hydroxide, and obtain neutralization slag and separation liquid after pressure filtration; add sodium thiram to the separation liquid to form sulfide precipitation from heavy metal impurities, and obtain sulfide slag and manganese dithionite containing manganese sulfate and manganese di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com