Red mud comprehensive utilization process

A technology of red mud and technology, which is applied in the field of industrial waste residue reuse, can solve problems such as environmental safety hazards, and achieve the effects of simplified procedures, high comprehensive utilization value, and large resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

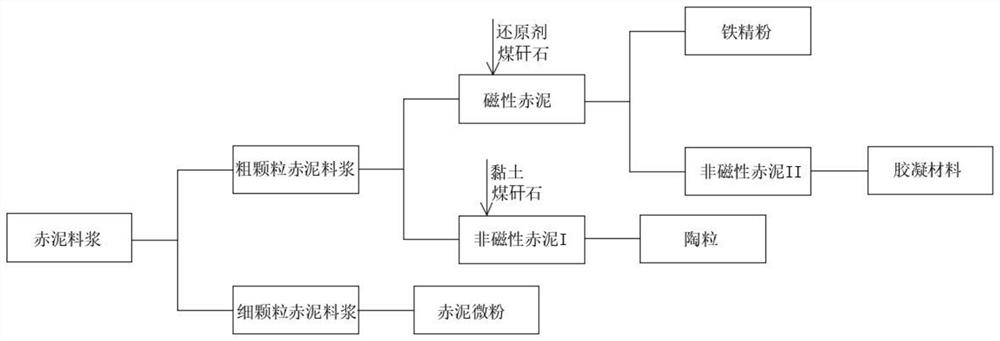

[0042] A red mud comprehensive utilization process, the specific steps are:

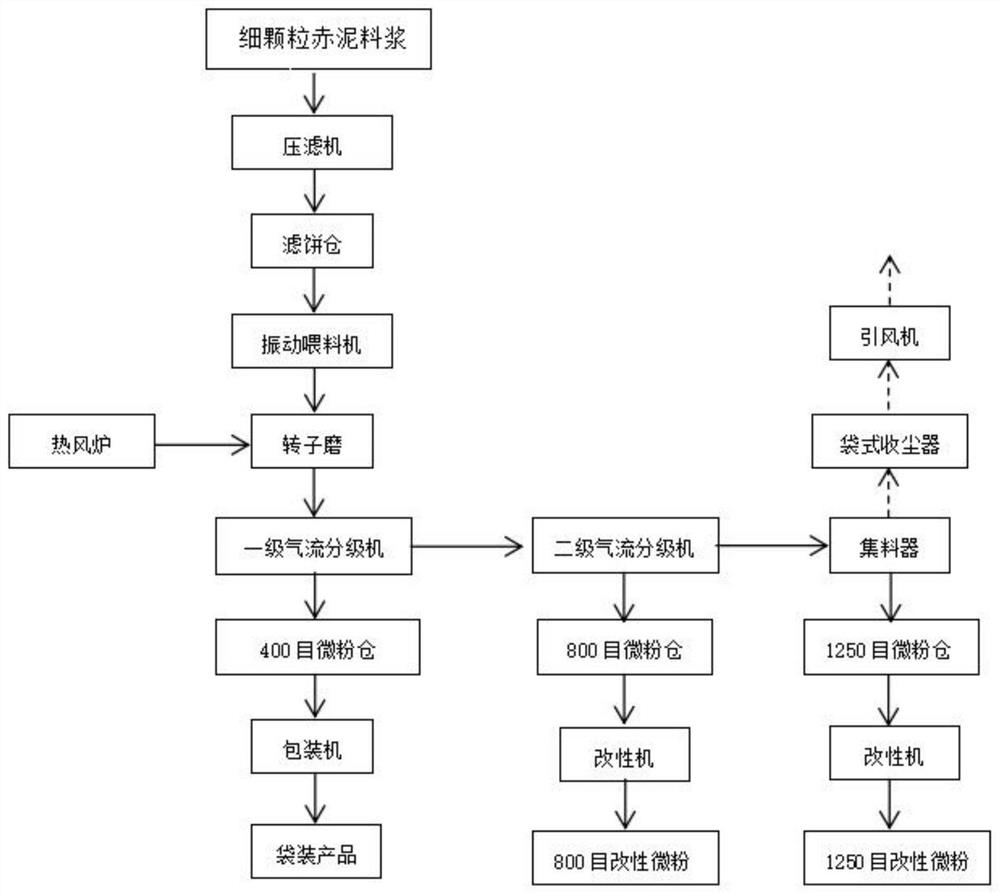

[0043] (1) Pretreating the red mud slurry according to particle size classification to obtain coarse-grained red mud slurry and fine-grained red mud slurry;

[0044] (2) Press-filter the coarse-grained red mud slurry after ball milling and primary magnetic separation to obtain magnetic red mud and non-magnetic red mud I;

[0045] (3) Adding reducing agent and coal gangue to magnetic red mud, extruding granulation, shaping and screening, drying and preheating, reducing roasting, water quenching, ball milling, secondary magnetic separation, and solid-liquid separation to obtain Iron concentrate and non-magnetic red mud II;

[0046] (4) preparing a gelled material from non-magnetic red mud II;

[0047] (5) After mixing the non-magnetic red mud I with coal gangue and clay, extruding granulation, preheating, roasting, and cooling to obtain ceramsite; the roasting temperature is 1200° C., and the roastin...

Embodiment 2

[0061] A red mud comprehensive utilization process, the specific steps are:

[0062] (1) Pretreating the red mud slurry according to particle size classification to obtain coarse-grained red mud slurry and fine-grained red mud slurry;

[0063] (2) Press-filter the coarse-grained red mud slurry after ball milling and primary magnetic separation to obtain magnetic red mud and non-magnetic red mud I;

[0064] (3) Adding reducing agent and coal gangue to magnetic red mud, extruding granulation, shaping and screening, drying and preheating, reducing roasting, water quenching, ball milling, secondary magnetic separation, and solid-liquid separation to obtain Iron concentrate and non-magnetic red mud II;

[0065] (4) preparing a gelled material from non-magnetic red mud II;

[0066] (5) Mix non-magnetic red mud I with coal gangue and clay, extrude and granulate, preheat, roast and cool to obtain ceramsite; the roasting temperature is 1100°C, and the roasting time is 50 minutes.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com