Method for extracting soft potassium magnesium vanadium from carnallite containing magnesium sulfate

A technology of carnallite ore and soft potassium magnesium vanadium, applied in the field of recovery of potassium and sulfate ion resources, can solve the problems of complex process and low recovery rate, achieve high recovery rate, avoid resource waste, and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

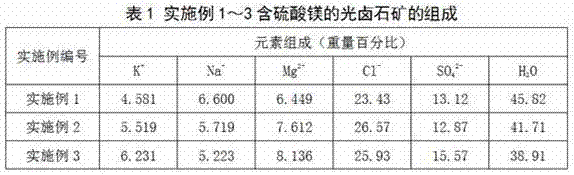

Embodiment 1

[0033] This embodiment includes the following steps:

[0034] (1) Decomposition: Mix carnallite ore containing magnesium sulfate with water, washing mother liquor, and soft potassium flotation mother liquor at a mass ratio of 1:0.12:0.06:0.37. The decomposition temperature is controlled at 25°C and stirred for 40 minutes to obtain decomposition. The final solid-liquid mixed pulp;

[0035] (2) Dehalogenation: filter the solid-liquid mixed pulp obtained in step (1) to achieve solid-liquid separation, and obtain solid salt and high-magnesium mother liquor. The chemical elements in the solid salt include: K + 5.54%, Na + 8.76%, Mg 2+ 4.51%, Cl - 19.56%, SO 4 2- 16.98%, the rest is water, keep it for use; the chemical element composition of high-magnesium mother liquor is: K + 1.68%, Na + 0.21%, Mg 2+ 7.01%, Cl - 19.56%, SO 4 2- 3.72%, the rest is water, which is discharged to the carnallite salt field and evaporated in a cycle;

[0036] (3) Transformation: Mix the soli...

Embodiment 2

[0046] This embodiment includes the following steps:

[0047] (1) Decomposition: Mix carnallite ore containing magnesium sulfate with water, washing mother liquor, and soft potassium flotation mother liquor at a mass ratio of 1:0.16:0.06:0.30, stir for 60 minutes, and control the decomposition temperature at 15°C. Obtain solid-liquid mixed pulp;

[0048] (2) Dehalogenation: filter the solid-liquid mixed pulp obtained in step (1) to achieve solid-liquid separation, and obtain solid salt and high-magnesium mother liquor. The chemical elements in the solid salt are composed of: K + 6.39%, Na + 8.46%, Mg 2+ 4.87%, Cl - 20.33%, SO 4 2- 17.23%, the rest is water, keep it for use; the chemical element composition of high-magnesium mother liquor is: K + 1.25%, Na + 0.335%, Mg 2+ 6.94%, Cl - 19.55%, SO 4 2- 3.18%, the rest is water, which is discharged to the carnallite salt field and evaporated in a cycle;

[0049] (3) Transformation: Mix the solid salt obtained in step (2...

Embodiment 3

[0059] This embodiment includes the following steps:

[0060] (1) Decomposition: Mix carnallite ore containing magnesium sulfate with water, washing mother liquor, and soft potassium flotation mother liquor at a mass ratio of 1:0.20:0.08:0.25, stir for 80 minutes, and control the decomposition temperature at 20°C. Obtain solid-liquid mixed pulp;

[0061] (2) Dehalogenation: filter the solid-liquid mixed pulp obtained in step (1) to achieve solid-liquid separation, and obtain solid salt and high-magnesium mother liquor. The chemical elements in the solid salt are composed of: K + 7.64%, Na + 8.257%, Mg 2+ 5.32%, Cl - 20.33%, SO 4 2- 20.12%, the rest is water, keep it for use; the chemical element composition of high-magnesium mother liquor is: K + 1.47%, Na + 0.369%, Mg 2+ 6.94%, Cl - 19.58%, SO 4 2- 3.48%, the rest is water, which is discharged to the carnallite salt field and evaporated in a cycle;

[0062] (3) Transformation: Mix the solid salt obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com