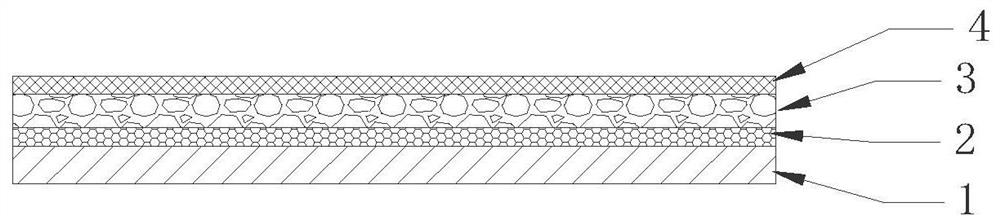

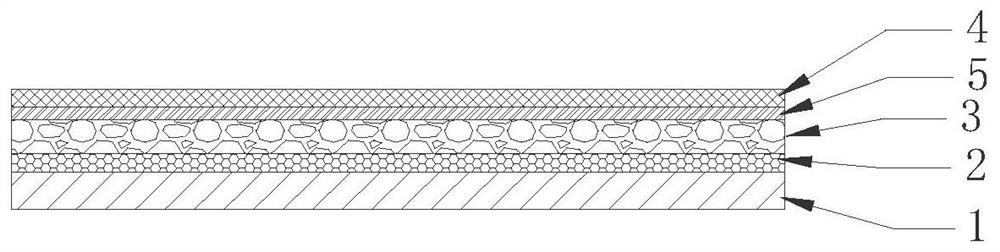

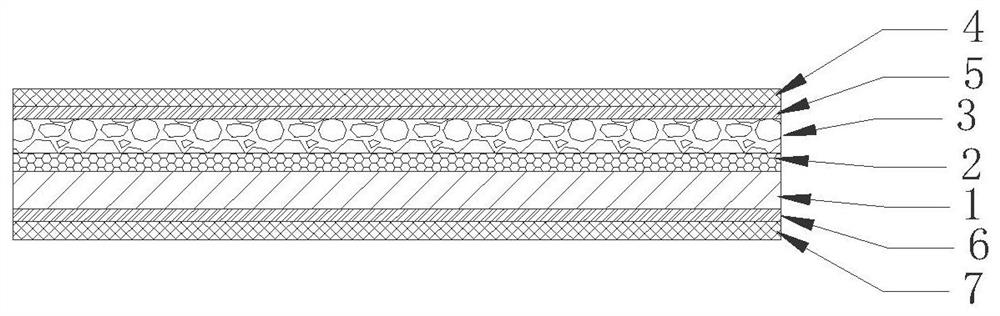

Environment-friendly cloth and preparation method thereof

An environmentally friendly, fabric technology, applied in the textile field, to achieve the effect of easy degradation, good physical strength and hydrophobic performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Further illustrate the preparation method of above-mentioned environment-friendly type cloth below, comprise steps:

[0053] S1: Collecting petals and / or leaves of plants. The collection time is preferably carried out from 4:00 am to 8:00 am. Since the general plant flowers and leaves are the brightest and fullest in color between 4:00 am and 8:00 am, the petals and leaves produced during this time period can be preserved. Original color, not easy to be distorted.

[0054] S2: Separate the petals and / or leaves, bake with tunnel microwave equipment for 2 minutes, then bake in air-energy drying equipment at 35-45°C for 0.5-1.5 hours, then heat up to 40-55°C for 0.5-1.5 hours , heat up to 60-70°C and bake for 1-2 hours to get the dry material. When separating the petals and / or leaves, manual or mechanical equipment can be used according to requirements, which is not limited here. The method of drying in sections is used to maintain the original color and texture of petals...

Embodiment 1

[0065] A preparation method of an environment-friendly cloth, comprising the steps of:

[0066] S1: Collect petals of plants. The collection time was at 4:00 am.

[0067] S2: Separate the petals, bake with tunnel microwave equipment for 2 minutes, then bake in air-energy drying equipment at 35°C for 1.5 hours, at 40°C for 1.5 hours, and at 60°C for 2 hours to produce dry material.

[0068] S3: Spray the adhesive on the surface of the cotton cloth, spray the adhesive on one side of the petals, leave it for 3 minutes, and discharge and paste the petals on the surface of the cotton cloth.

[0069] S4: Using pressure hydraulic equipment, put the cotton cloth with the discharged petals on the hydraulic equipment and heat it to 50 degrees, pressure 20MP, press for 3 minutes, then reduce the pressure to 0MP for 25 seconds, then pressurize to 20MP, heat up to 68℃, hot press 6 Shaped in minutes.

[0070] S5: Surface treatment: Spray the wear-resistant hydrophobic paint on the petals...

Embodiment 2

[0072] A preparation method of an environment-friendly cloth, comprising the steps of:

[0073] S1: Collect petals and leaves of plants. The collection time was at 6:00 am.

[0074] S2: Separate the petals and leaves, bake with tunnel microwave equipment for 2 minutes, then bake in air-energy drying equipment at 40°C for 1 hour, at 50°C for 1 hour, and at 65°C for 1.5 hours to produce dry material.

[0075] S3: Spraying the adhesive on the surface of the linen, spraying the adhesive on one side of the petals and leaves, leaving it for 5 minutes, and pasting the petals and leaves on the surface of the linen.

[0076] S4: Using pressure hydraulic equipment, heat the linen cloth with petals and leaves on the hydraulic equipment to 55 degrees, pressure 25MP, press for 2 minutes, then reduce the pressure to 0MP for 20 seconds, then pressurize to 25MP, heat up to 70℃, heat Press for 4 minutes to form.

[0077] S51: Spray the flame retardant onto the upper and lower surfaces of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com