Green terpin hydrate and terpilenol production methods

A terpene diol hydrate, green production technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve problems such as reducing product competitiveness, increasing production costs, polluting the environment, and achieving Strong versatility, saving production water, and reducing acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

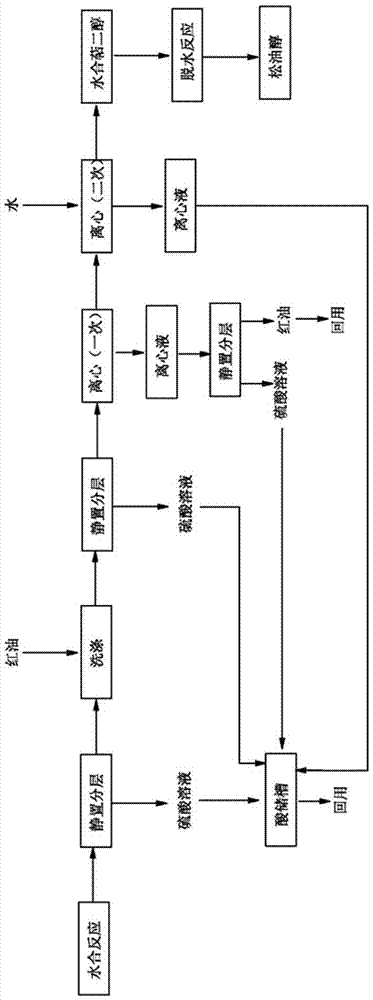

Method used

Image

Examples

Embodiment 1

[0033] Step 1: First, add 1.4 tons of 30% sulfuric acid solution and 1 ton of turpentine to the reaction tank for hydration reaction. After the hydration reaction, let the reaction materials stand for 5 minutes, drain the lower layer of acid solution to the acid storage tank, and then add red The quality of adding oil and red oil is 0.7 times of the input raw material;

[0034] Step 2: Stir for 3-5 minutes to fully disperse the reaction materials into the red oil, stop stirring, let stand for stratification for 10 minutes, and drain the acid water precipitated in the lower layer into the acid water storage tank; after the acid water is drained, the material Discharge into the semi-finished product storage tank;

[0035] Step 3: Put the material in the semi-finished product storage tank into the centrifuge for centrifugation, separate the water and oil in the material, and stop the centrifugation until there is no liquid flowing out of the centrifuge; obtain solid centrifuged m...

Embodiment 2

[0039] Step 1: First, add 1.4 tons of 30% sulfuric acid solution and 1 ton of turpentine to the reaction tank for hydration reaction. After the hydration reaction, let the reaction materials stand for 5 minutes, drain the lower layer of acid solution to the acid storage tank, and then add red The quality of adding oil and red oil is 1.0 times of the input raw material;

[0040] Step 2: Stir for 3-5 minutes to fully disperse the reaction materials into the red oil, stop stirring, let stand for stratification for 10 minutes, and drain the acid water precipitated in the lower layer into the acid water storage tank; after the acid water is drained, the material Discharge into the semi-finished product storage tank;

[0041] Step 3: Put the material in the semi-finished product storage tank into the centrifuge for centrifugation, separate the water and oil in the material, and stop the centrifugation until there is no liquid flowing out of the centrifuge; obtain solid centrifuged m...

Embodiment 3

[0045] Step 1: First, add 1.4 tons of 30% sulfuric acid solution and 1 ton of turpentine to the reaction tank for hydration reaction. After the hydration reaction, let the reaction materials stand for 5 minutes, drain the lower layer of acid solution to the acid storage tank, and then add red oil ; The addition of red oil is 1.4 times of input raw material;

[0046]Step 2: Start stirring for 3-5 minutes to fully disperse the reaction materials into the red oil, stop stirring, let stand for 5 minutes, and drain the acid water precipitated in the lower layer into the acid storage tank; after the acid water is drained, the materials are discharged into the Semi-finished product storage tank;

[0047] Step 3: Put the material in the semi-finished storage tank into the centrifuge in the centrifuge, separate the water and oil in the material, and stop the centrifugation until no liquid flows out of the centrifuge; obtain solid centrifuged material and centrifuged liquid, and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com