A high-efficiency and energy-saving reaction process and reaction system for alcohol ether ester solvents

The technology of alcohol ether solvent and ester solvent is applied in the high-efficiency and energy-saving reaction process and reaction system field of alcohol ether ester solvent, and can solve the problems of restricting the use of basic catalysts, high energy consumption for separation, producing industrial waste water, and the like, Achieve the effect of increasing the cost of wastewater treatment, reducing the difficulty of separation and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

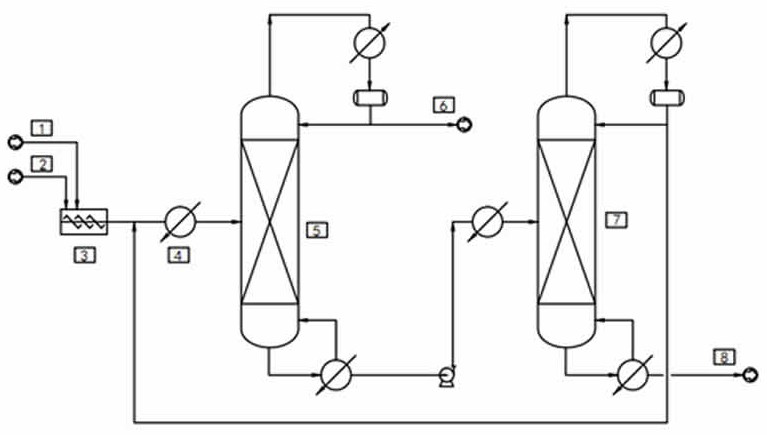

[0022] The invention discloses a high-efficiency and energy-saving reaction process for alcohol ether ester solvents, which comprises the following steps:

[0023] (1) According to the ratio of 1:1 to 1:3, the alcohol ether solvent and ethyl acetate are mixed evenly into the static mixer from the ethylene glycol ether or propylene glycol ether feed pump and the ethyl acetate feed pump, and enter the reaction The rectification tower reacts, the reaction pressure is 0.1Mpa-3Mpa, and the reaction temperature is 90-110°C;

[0024] (2) Excessive ethyl acetate and the ethanol generated by the reaction are removed from the top of the reaction distillation column after pressurization, and enter the esterification system of ethyl acetate as the head ester for recycling;

[0025] (3) The alcohol ether ester solvents and unreacted alcohol ether solvents produced by the reaction enter the light removal tower to remove the unreacted alcohol ether solvents, and the finished alcohol ether es...

Embodiment 2

[0028] The invention discloses a high-efficiency and energy-saving reaction process for alcohol ether ester solvents, which comprises the following steps:

[0029] (1) According to the ratio of 1:3, the alcohol ether solvent and ethyl acetate are mixed evenly by the ethylene glycol ether or propylene glycol ether feed pump and the ethyl acetate feed pump into the static mixer, and then enter the reactive distillation column for further mixing. Reaction, the reaction pressure is 1.55Mpa, and the reaction temperature is 90°C;

[0030] (2) Excessive ethyl acetate and the ethanol generated by the reaction are removed from the top of the reaction distillation column after pressurization, and enter the esterification system of ethyl acetate as the head ester for recycling;

[0031] (3) The alcohol ether ester solvents and unreacted alcohol ether solvents produced by the reaction enter the light removal tower to remove the unreacted alcohol ether solvents, and the finished alcohol et...

Embodiment 3

[0040] The invention discloses a high-efficiency and energy-saving reaction process for alcohol ether ester solvents, which comprises the following steps:

[0041] (1) According to the ratio of 1:1, the alcohol ether solvent and ethyl acetate are mixed evenly by the ethylene glycol ether or propylene glycol ether feed pump and the ethyl acetate feed pump into the static mixer, and then enter the reactive distillation column for further mixing. Reaction, the reaction pressure is 3Mpa, the reaction temperature is 100°C;

[0042] (2) Excessive ethyl acetate and the ethanol generated by the reaction are removed from the top of the reaction distillation column after pressurization, and enter the esterification system of ethyl acetate as the head ester for recycling;

[0043] (3) The alcohol ether ester solvents and unreacted alcohol ether solvents produced by the reaction enter the light removal tower to remove the unreacted alcohol ether solvents, and the finished alcohol ether es...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com