Method for preparing spherical amorphous silicon aluminum carrier

A technology of amorphous silica-alumina and spherical carrier, which is applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc. It can solve the problems of uneven particle size in shaping and granulation, large dust in the preparation process, and complicated process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

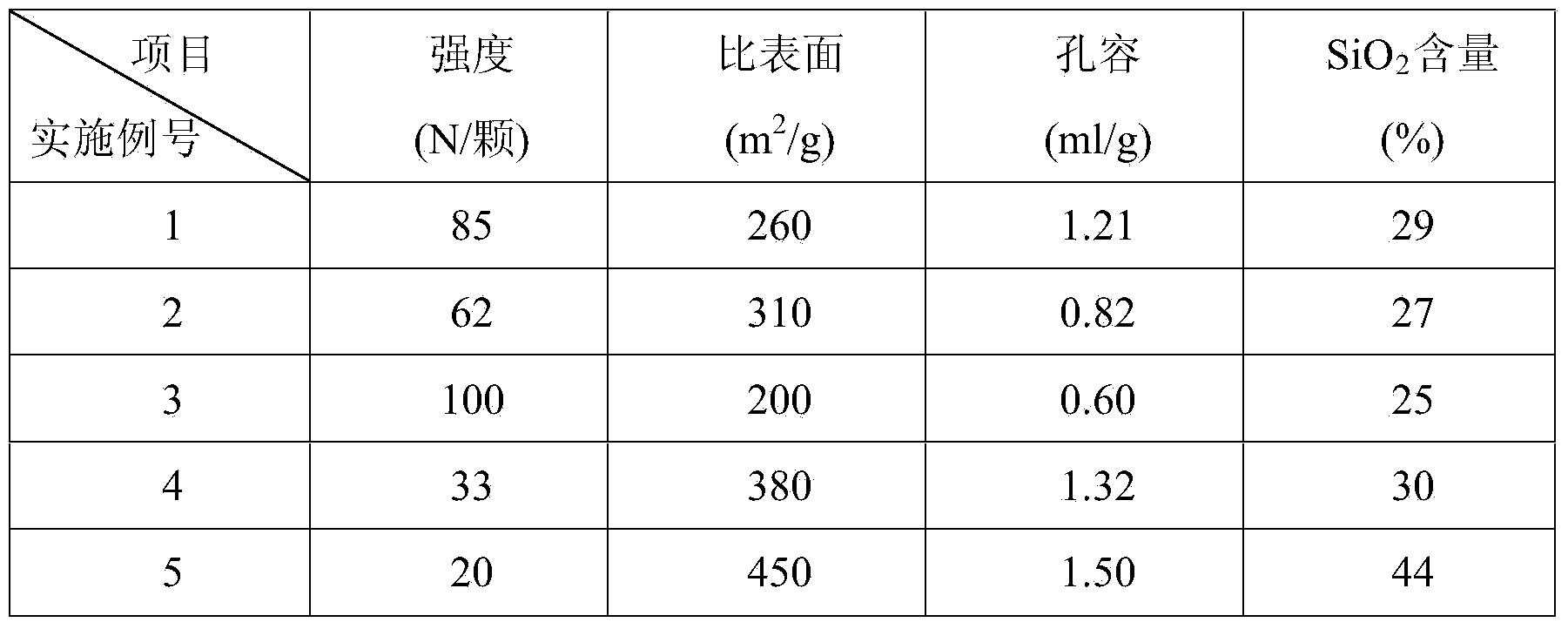

Embodiment 1

[0024] 100g Al 2 o 3 / L sodium metaaluminate solution 180ml, 70g SiO 2 / L sodium silicate solution 190ml and 100gAl 2 o 3 Add 140ml of / L aluminum sulfate solution to the reaction vessel with 200ml of deionized water in parallel flow, keep the reaction temperature at 35-40°C, and the pH value at 8.0-8.5, add it in 1.0 hour, then heat to 80°C for aging for 2.0 hours , solid-liquid separation, fully beating and washing with deionized water, and suction filtration to obtain 138 g of amorphous silicon-aluminum composite oxide filter cake with a solid content of 33%. The above-mentioned filter cake was added in batches to 150 ml of an aqueous solution of sodium alginate with a mass fraction of 2.5%, and fully stirred and mixed to obtain a suspension with a dynamic viscosity of 260 mPa·s. Then the suspension was dropped into 0.5 mol / L aluminum nitrate aqueous solution, gelled for 5min, and formed silicon-aluminum composite oxide-sodium alginate gel pellets, further washed with d...

Embodiment 2

[0026] 200g Al 2 o 3 / L sodium metaaluminate solution 150ml, 100g SiO 2 / L sodium silicate solution 200ml and 200gAl 2 o 3Add 110ml of / L aluminum sulfate solution to the reaction vessel with 200ml of deionized water in parallel flow, keep the reaction temperature at 30-35°C, and the pH value at 7.5-8.0, add it in 2.0 hours, then heat to 85°C for 1.0 hour aging , solid-liquid separation, fully beating and washing with deionized water, and suction filtration to obtain 200 g of amorphous silicon-aluminum composite oxide filter cake with a solid content of 36%. The above filter cake was added in batches to 260 ml of an aqueous solution of sodium alginate with a mass fraction of 1.5%, and fully stirred and mixed to obtain a suspension with a dynamic viscosity of 150 mPa·s. Then the suspension was dropped into 2.0 mol / L calcium nitrate aqueous solution, gelled for 1 min to form silica-alumina composite oxide-sodium alginate gel beads, further washed with deionized water, dried ...

Embodiment 3

[0028] 150g Al 2 o 3 / L sodium metaaluminate solution 180ml, 150g SiO 2 / L sodium silicate solution 100ml and 180gAl 2 o 3 Add 103ml of / L aluminum sulfate solution to the reaction container that has been added with 300ml of deionized water in parallel, keep the reaction temperature at 35-40°C, and the pH value at 7.0-7.5, add it in 0.5 hours, then heat to 75°C and age for 2.0 hours , solid-liquid separation, fully beating and washing with deionized water, and suction filtration to obtain 152 g of amorphous silicon-aluminum composite oxide filter cake with a solid content of 40%. The above filter cake was added in batches to 260 ml of an aqueous solution of sodium alginate with a mass fraction of 4.0%, and fully stirred and mixed to obtain a suspension with a dynamic viscosity of 450 mPa·s. Then drop the suspension into 2mol / L ferric nitrate aqueous solution and gel for 1min to form silica-aluminum composite oxide-sodium alginate gel pellets, which are further washed with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com