Catalyst for oxidation of mercaptan in light oil products and its preparation method and application

A technology for mercaptan oxidation and light oil products, which is applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc. Process insecurity and other problems, to achieve the effect of safe preparation process, not easy to run off, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

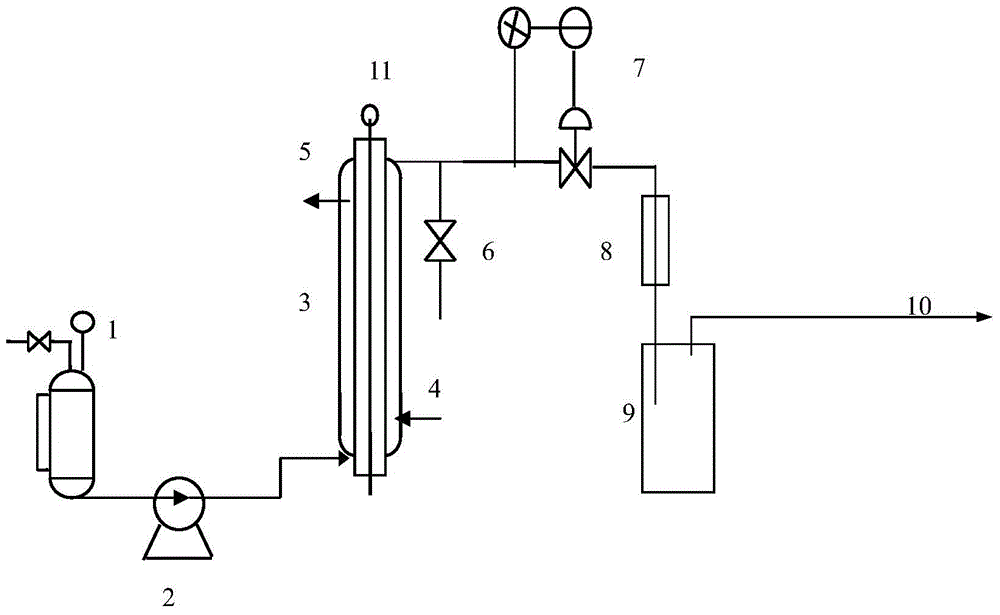

Method used

Image

Examples

Embodiment 1

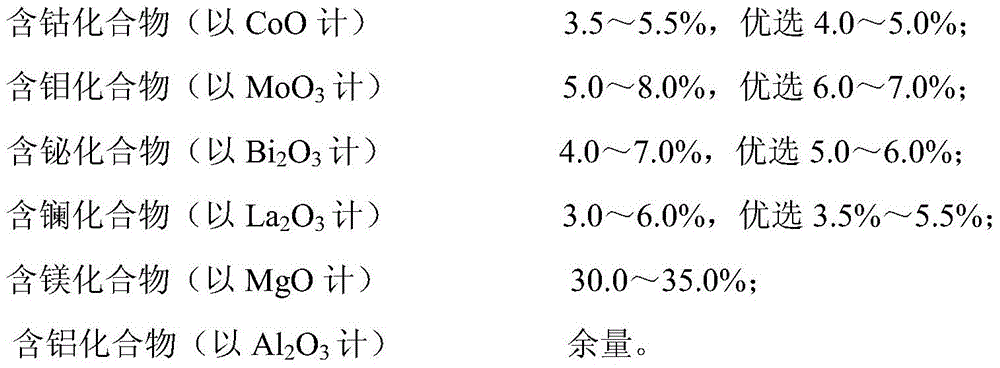

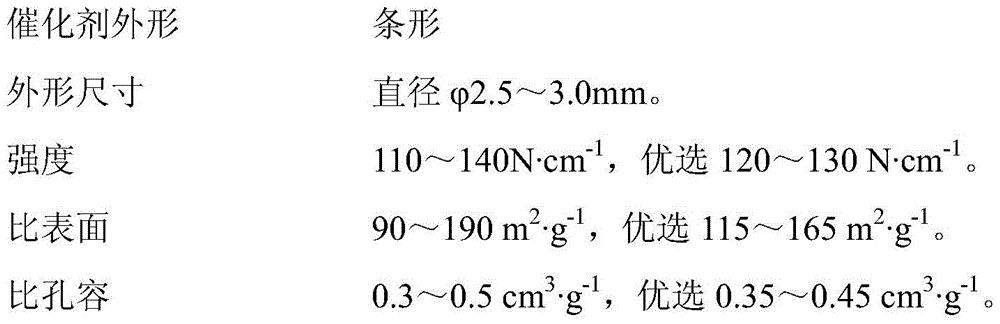

[0034] Catalyst C-1:

[0035] Weigh 21.30g Co(NO 3 ) 2 ·6H 2 O, 6.80g (NH 4 ) 2 · MoO 4 , 11.50g Bi(NO 3 ) 3 ·5H 2 O, 14.60gLa(NO 3 ) 3 ·6H 2 O, 6.00 g of citric acid was added to 40 ml of deionized water, mechanically stirred and heated to 80° C., and a solution A containing four active components of cobalt, molybdenum, bismuth, and lanthanum was prepared in one step.

[0036] Mix 33.00g of light magnesia, 45.50g of pseudo-boehmite, and 3.00g of scallop powder as a powdery solid compound, add solution A, knead evenly; extrude into strips.

[0037] Leave at room temperature to dry naturally. By means of gradient heating, the temperature was raised from 20°C to 120°C over 1 hour, kept at 120°C for 1 hour, then raised to 300°C over 1 hour, kept at constant temperature for 1 hour, finally raised to 550°C, and calcined for 2 hours to obtain catalyst C-1. See Table 1 for the mass percentages of active components and carrier components in the prepared catalyst, and see ...

Embodiment 2

[0040] Catalyst C-2:

[0041] Weigh 19.40gCo(NO 3 ) 2 ·6H 2 O, 8.17g (NH 4 ) 2 · MoO 4 , 14.60gBi (NO 3 ) 3 ·5H 2 O, 15.90gLa(NO 3 ) 3 ·6H 2 O, 6.00 g of citric acid was added to 40 ml of deionized water, mechanically stirred and heated to 80° C., and a solution A containing four active components of cobalt, molybdenum, bismuth, and lanthanum was prepared in one step.

[0042] Mix 30.00g of light magnesia, 46.00g of pseudoboehmite, and 3.00g of scallop powder as a powdery solid compound, add solution A, knead evenly; extrude into strips.

[0043] Leave at room temperature to dry naturally. By means of gradient heating, the temperature was raised from 20°C to 120°C over 1 hour, kept at 120°C for 1 hour, then raised to 300°C over 1 hour, held at the temperature for 1 hour, finally raised to 550°C, and calcined for 4 hours to obtain catalyst C-2. See Table 1 for the mass percentages of active components and carrier components in the prepared catalyst, and see Table 2 f...

Embodiment 3

[0046] Catalyst C-3:

[0047] Weigh 17.50gCo(NO 3 ) 2 ·6H 2 O, 8.85g (NH 4 ) 2 · MoO 4 , 12.50gBi (NO 3 ) 3 ·5H 2 O, 10.6gLa(NO 3 ) 3 ·6H 2 O, 6.00 g of citric acid was added to 40 ml of deionized water, mechanically stirred and heated to 80° C., and a solution A containing four active components of cobalt, molybdenum, bismuth, and lanthanum was prepared in one step.

[0048] Mix 35.00g of light magnesia, 44.00g of pseudoboehmite, and 3.00g of scallop powder as a powdery solid compound, add solution A, knead evenly; extrude into strips.

[0049] Leave at room temperature to dry naturally. By means of gradient heating, the temperature was raised from 20°C to 120°C over 1 hour, kept at 120°C for 1 hour, then raised to 300°C over 1 hour, held at the temperature for 1 hour, finally raised to 500°C, and calcined for 3 hours to obtain catalyst C-3. See Table 1 for the mass percentages of active components and carrier components in the prepared catalyst, and see Table 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com