Method for producing tuna fish pieces

A technology of tuna and tuna meat, applied in the direction of processing fish, forming food, cutting fish into parts, etc. It can solve the problems of fiber damage, separation, loss of impression of meat pieces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

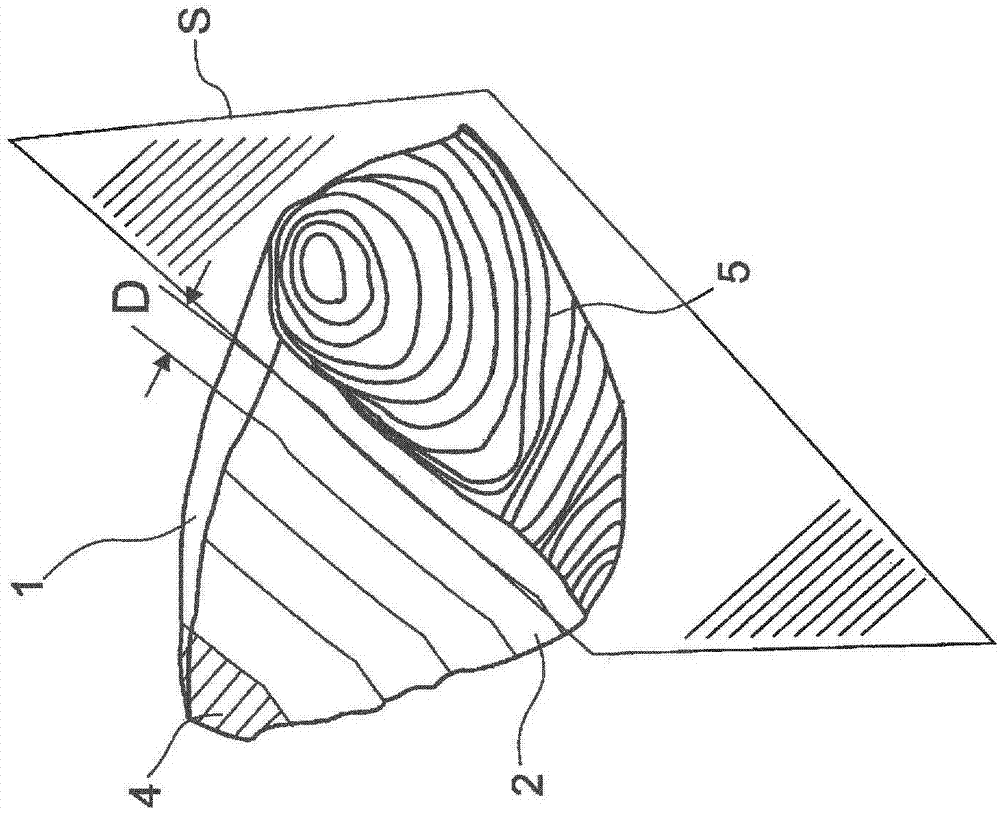

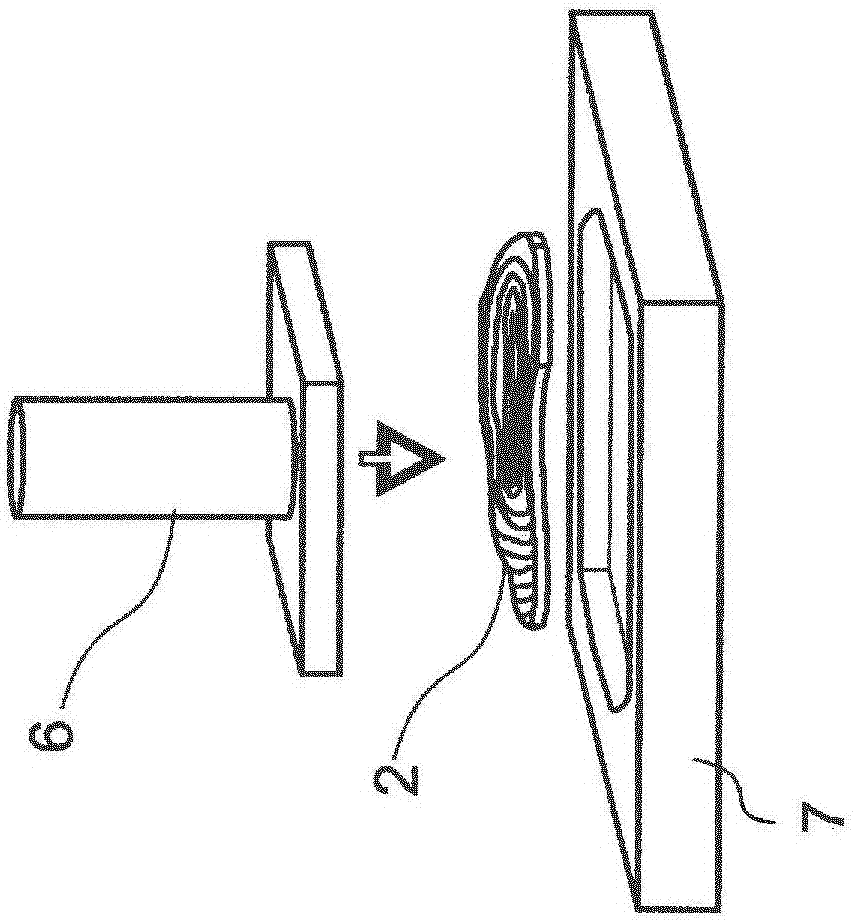

[0067] figure 1 The input material in the form of back fillets or pieces of fillet is schematically shown. As is known, such pieces of meat decrease continuously in size from front to back. Here, the tuna fillets are to be produced with the method according to the invention as objects 2 not only of the same weight but also of uniform dimensions.

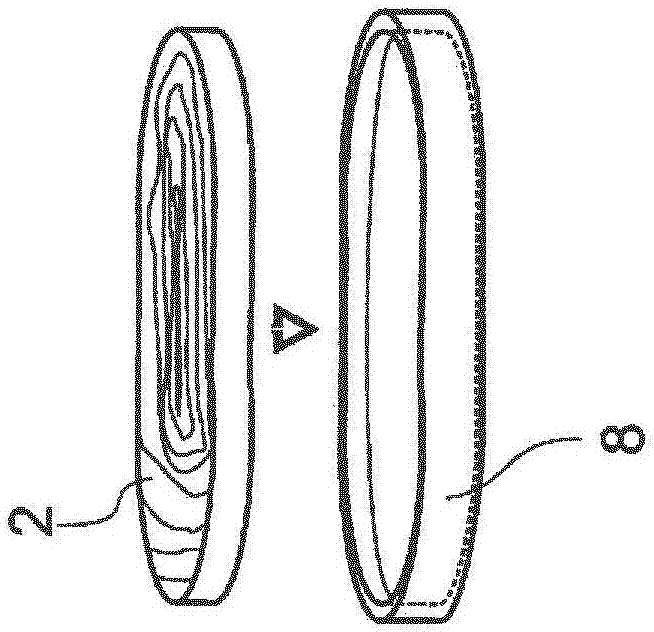

[0068] This method can be used, for example, to be able to provide the same item 2 as output material for finished food products or in large kitchens. On the one hand, this has the advantage that the consumer will find the same shape of the item 2 in each package and thus infer that the tuna portion is of uniform quality and size.

[0069] Another advantage which is important especially in food preparation in large galleys, such as cruise ship restaurants, is that objects 2 of the same size and dimensions can be prepared uniformly. Thus, for example, a large number of items 2 placed next to each other can be prepared in a food ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com