Method for coupling a laser beam into a liquid jet beam

A laser beam, liquid technology, applied in the direction of laser welding equipment, metal processing equipment, welding equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

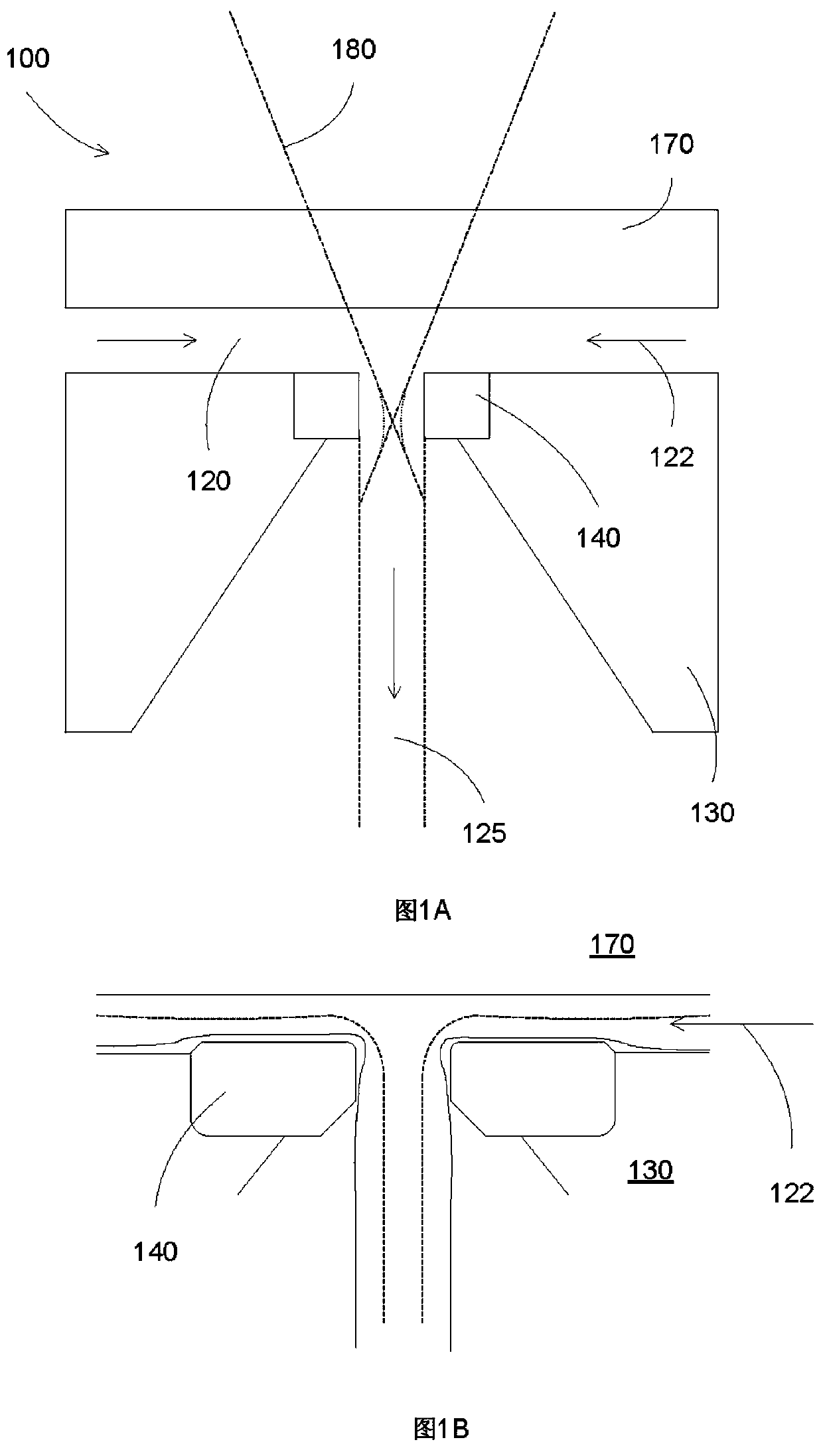

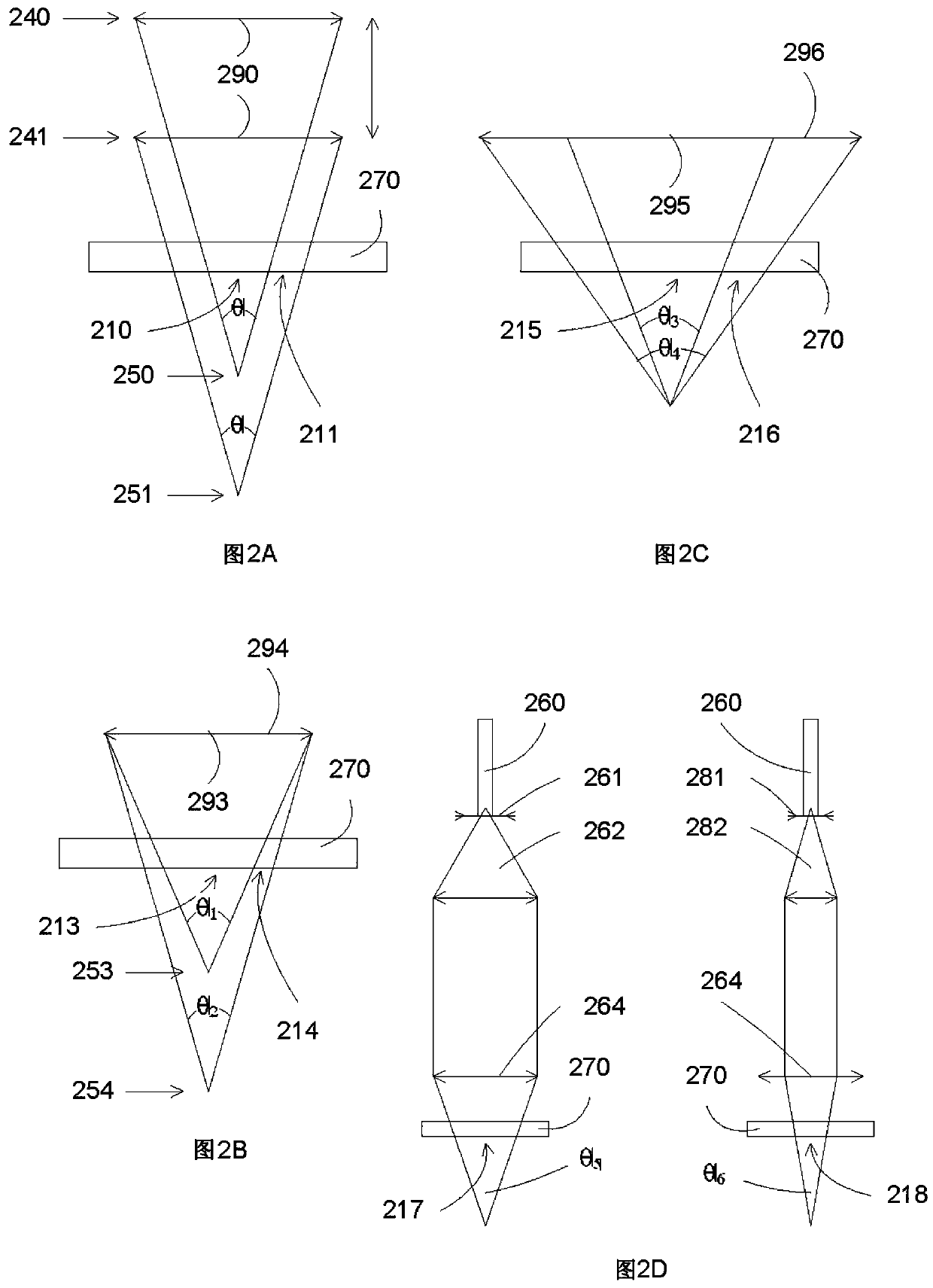

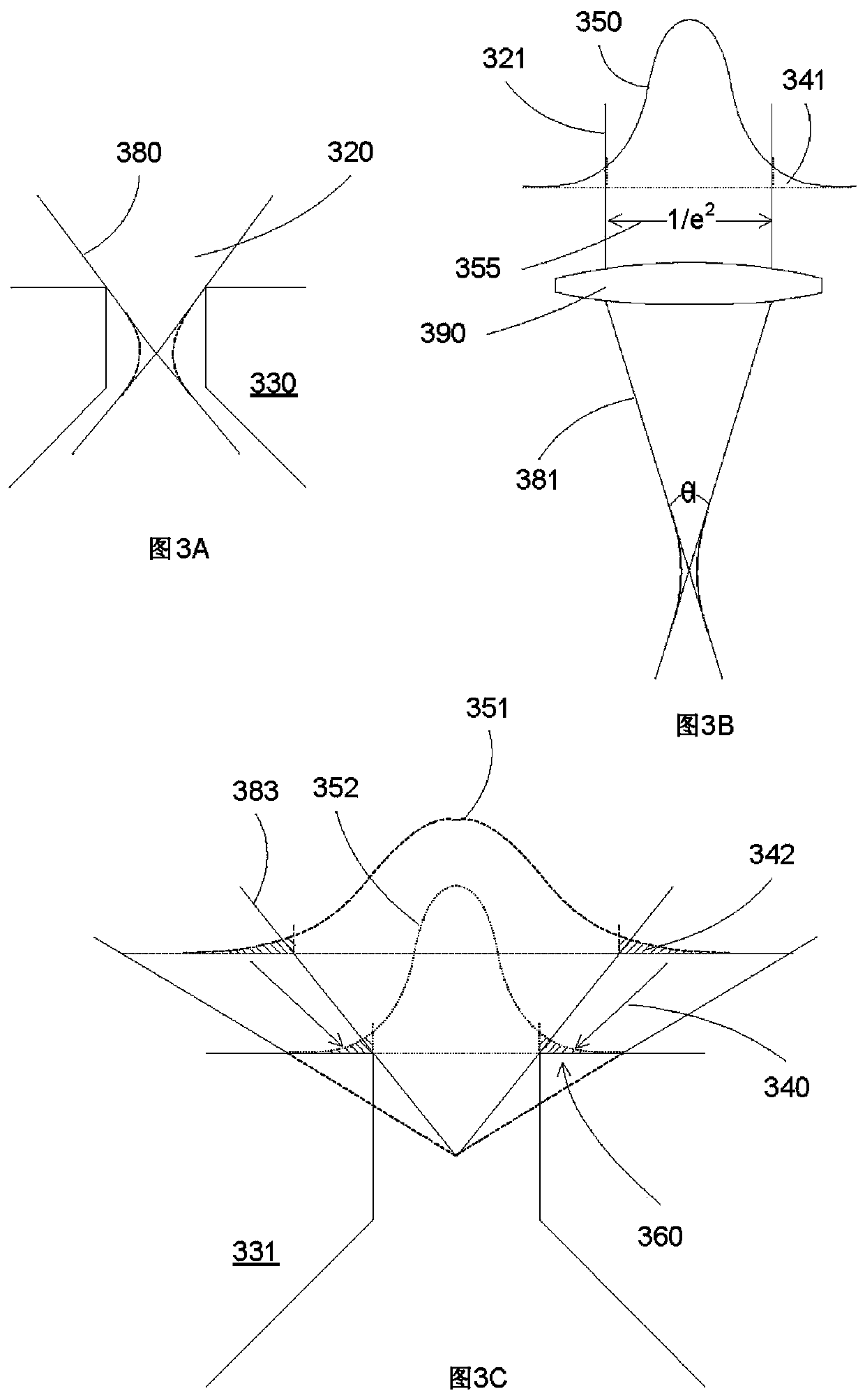

[0018] In some embodiments, the present invention relates to a liquid jet guided laser system that can generate a laser beam contained within a liquid jet. Laser technology is suitable for a wide variety of material processing tasks such as cutting, drilling, welding, marking, engraving and ablating materials. Almost all materials such as metals, metal alloys, ceramics, diamonds, synthetic diamonds, carbon fibers, sapphires, quartz, glass, plastics, etc. can be processed. In almost all cases, a focusing lens is used to focus the laser light into a very small spot, allowing the laser energy to exceed the damage threshold of the workpiece material to process the workpiece. The workpiece must therefore be precisely aligned at the laser focus point at all times during the entire process. In liquid jet-guided laser technology, a coupling unit is used to couple the laser focus into a thin liquid jet, so that the laser focus energy is kept over the entire length of the liquid jet. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com