Translucent fibre composite materials comprising chemically modified polymers

A fiber composite material, thermoplastic polymer technology, applied in chemical instruments and methods, optical components, building components, etc., can solve the problems of high viscosity, low resistance, poor applicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

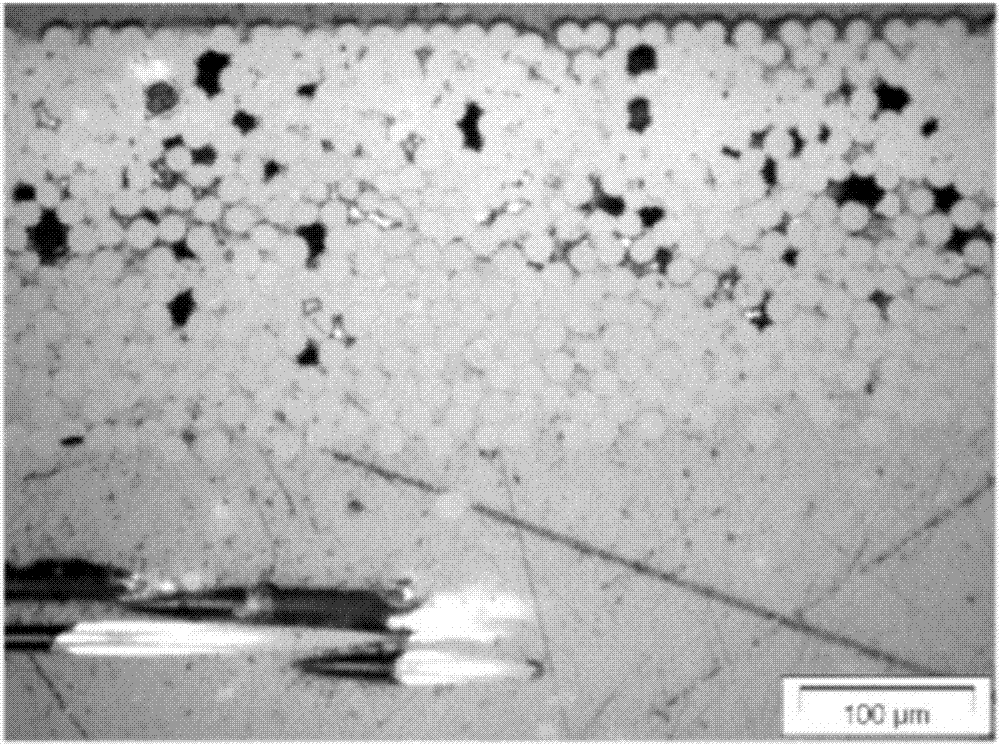

[0521] Example 1: Production of Fiber Composite M

[0522] Acrylonitrile-styrene-maleic anhydride copolymer in the form of thermoplastic molding composition A (prepared from 75% by weight of styrene, 24% by weight of acrylonitrile and 1% by weight of maleic anhydride) based on 40% by weight of the fiber composite ) with 60% by weight, based on the fiber composite, of glass-based reinforcing fibers [GW 123-580K2 from P-D Glasseiden GmbH] having chemically reactive functional groups (silane groups) at the surface.

Embodiment 2

[0523] Example 2: Creation of Fiber Composite N

[0524] Acrylonitrile-butadiene-styrene copolymer in the form of thermoplastic molding composition A (composed of 45% by weight of butadiene, 30% by weight of styrene, 24% by weight of and 1% by weight of maleic anhydride) with 35% by weight of glass-based reinforcing fibers with chemically reactive functional groups (silane groups) at the surface based on fiber composites [GW 123-580K2 from P-D Glasseiden GmbH] For compounding. The fiber composite is then ribbed.

Embodiment 3

[0525] Example 3: Production of shaped articles from fiber composite materials M and N

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com