Arrangement of an impeller on a rotating part and method for producing the arrangement

A technology of rotating parts and impellers, applied in the field of producing such components, can solve disadvantages, difficulties and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

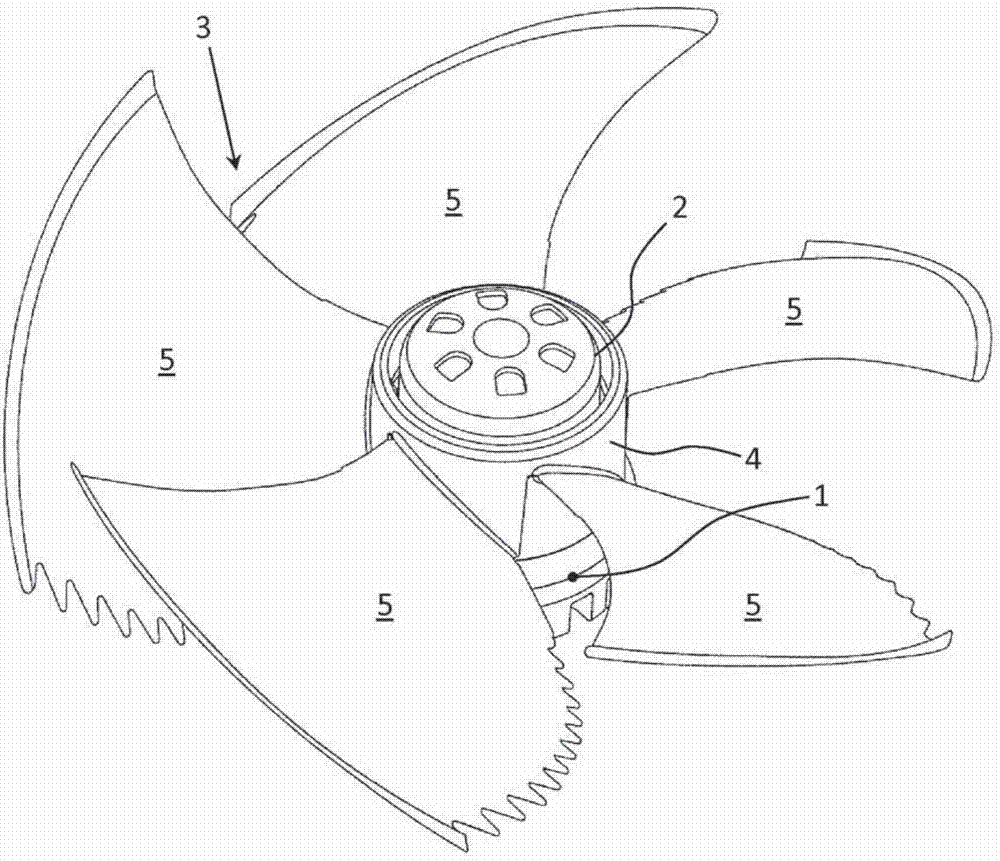

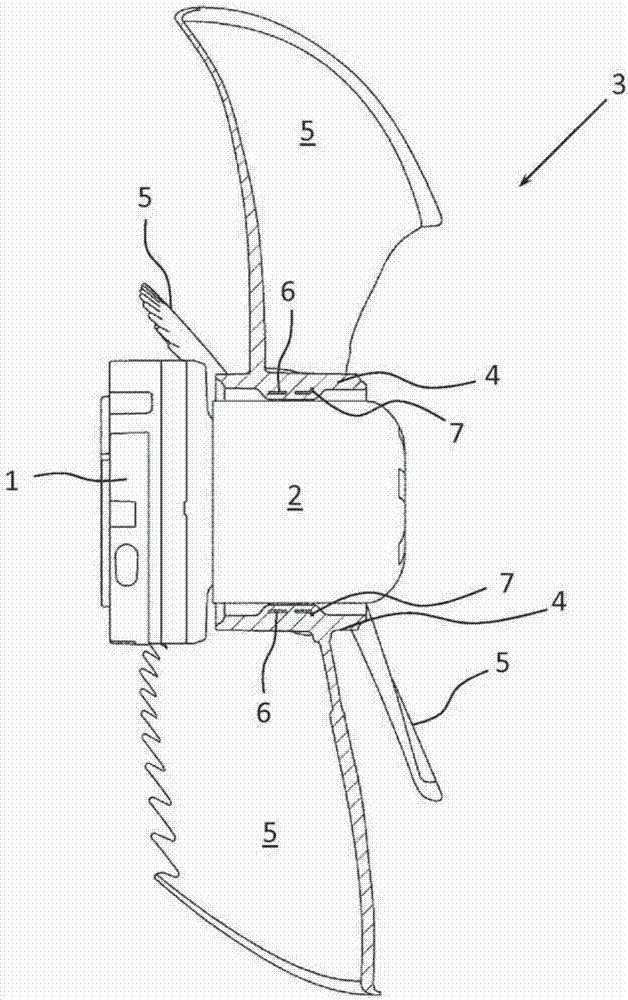

[0035] figure 1 An assembly according to the invention is shown schematically, comprising an electric motor 1 with a rotor 2 to which an impeller, hereinafter referred to as fan wheel 3 , is press-fitted. The non-rotational connection between the hub 4 of the fan wheel 3 and the rotor 2 or the surface of the rotor 2 is produced by a press fit.

[0036] The blades 5 are provided with aerodynamic features which do not play a role with regard to the teaching according to the invention.

[0037] At this point it should be noted that the fan wheel 3 is press-fitted onto the rotor 2 in order to form a specific flow direction. For the opposite flow direction, without changing the type and design of the fan wheel 3, it can be formed by press-fitting the fan wheel 3 on the rotor facing in the other direction.

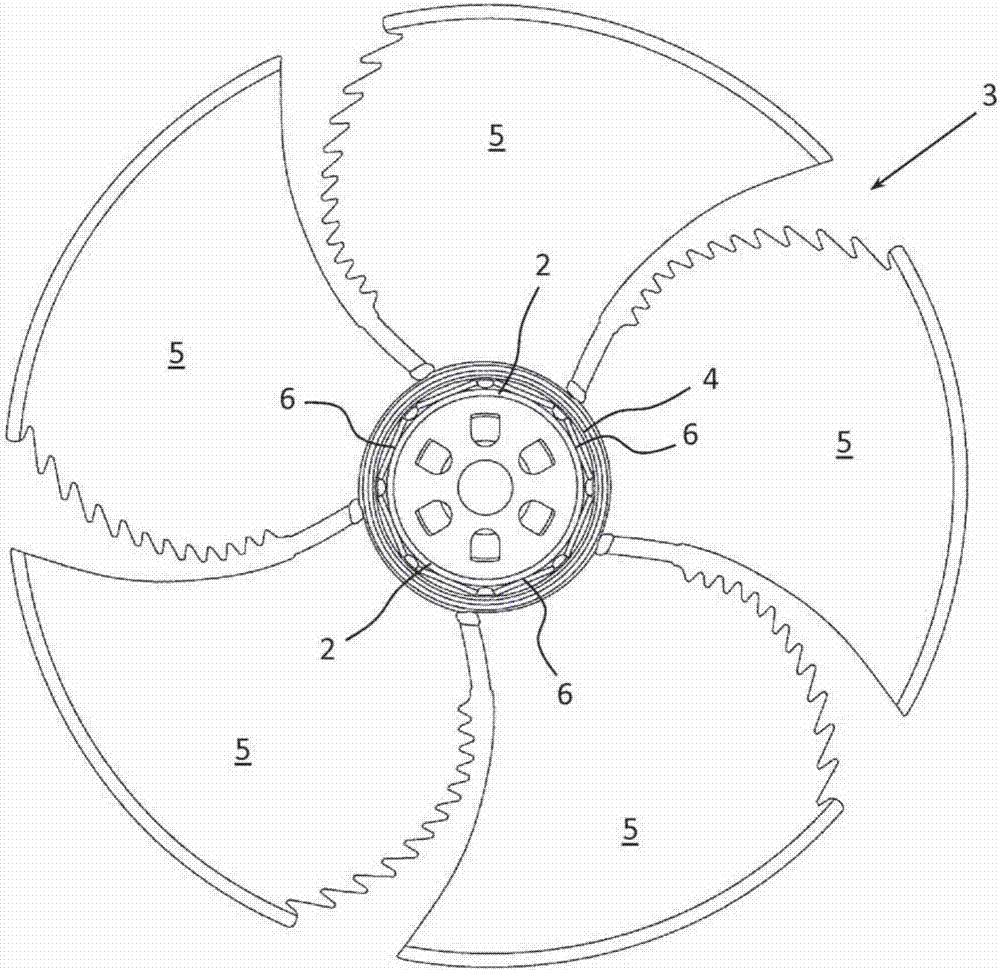

[0038] figure 2 shown in top view figure 1 , wherein it can be seen in the schematic diagram that the polygonal annular blank 6 is between the hub 4 of the fan wheel 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com