Bearing bush type rotation wheel base device

A technology of the wheel seat and bearing bush, which is applied in the field of connecting parts of the wheel mechanism, can solve the problems of cumbersome replacement of the wheel and the inability to meet the installation angle requirements of different wheels, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

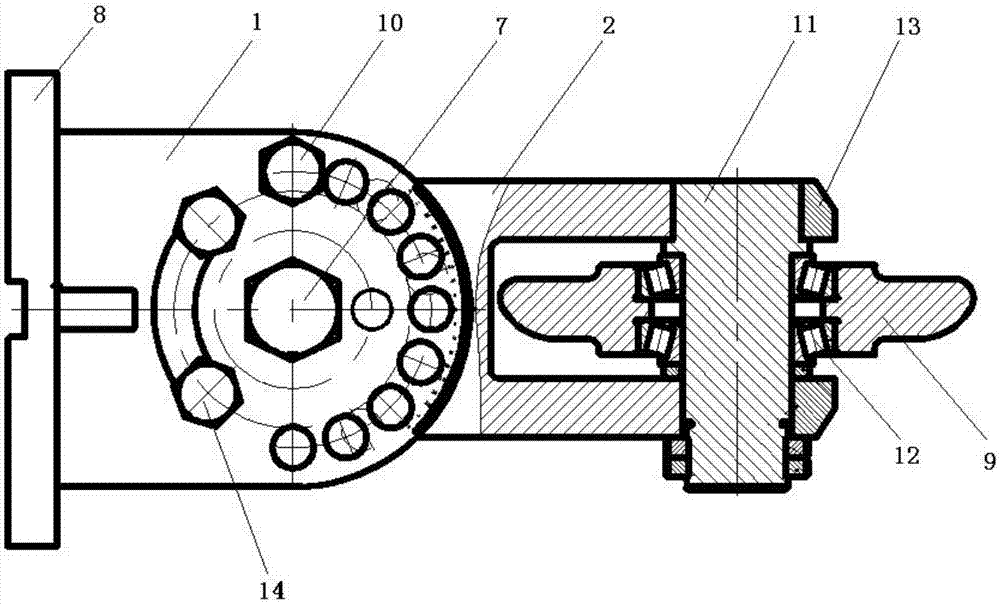

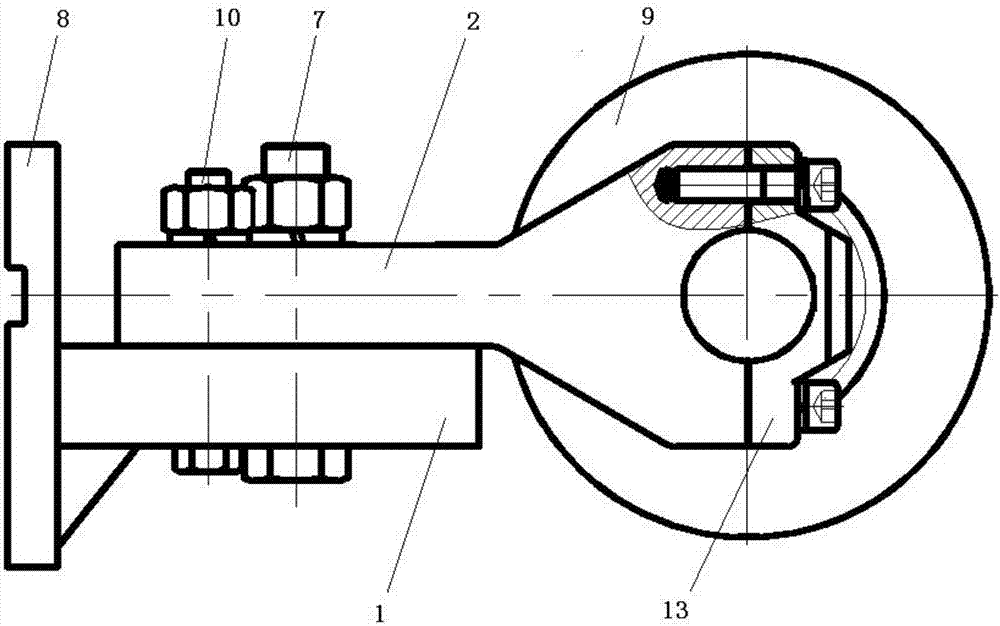

[0030] Such as Figures 1 to 7 shown. The invention discloses a bearing pad type rotary wheel seat device, which comprises a rotary wheel mechanism for spinning a workpiece. The rotary wheel mechanism is installed on a spinning machine tool through a connecting arm, and the connecting arm is an angle-adjustable structure, which includes Connecting plate 1, wheel arm 2;

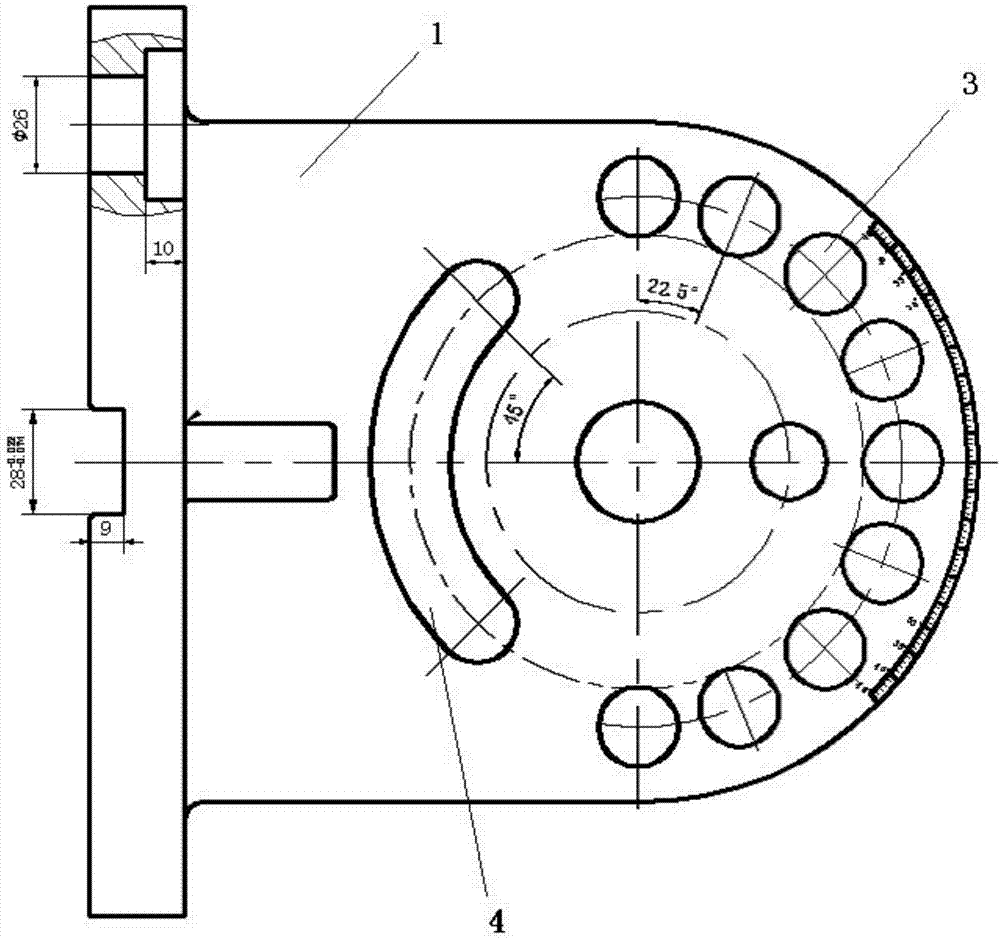

[0031] On the arc line of the right edge of the connecting plate 1, there are a plurality of A hinged hole arrays 3 formed by hinged holes with the same diameter at equidistant intervals, and there is also a connecting plate arc on the arc line of the left edge of the connecting plate 1. slot 4;

[0032] The wheel arm 2 includes a disk, and the circular arc on the right edge of the disk is equidistantly distributed with a plurality of B hinged hole arrays 5 made of hinged holes with the same diameter. There is a circular arc groove 6 of the wheel arm;

[0033] The connecting plate 1 and the disk of the whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com