Method for synthesizing butylated amino resin from pentahydroxymethyl melamine

A technology of pentamethylol melamine and amino resin, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as unfavorable environmental protection discharge, troublesome water treatment, and unfavorable filtration. Achieve the effect of reducing subsequent filtration requirements and costs, and reducing the amount of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

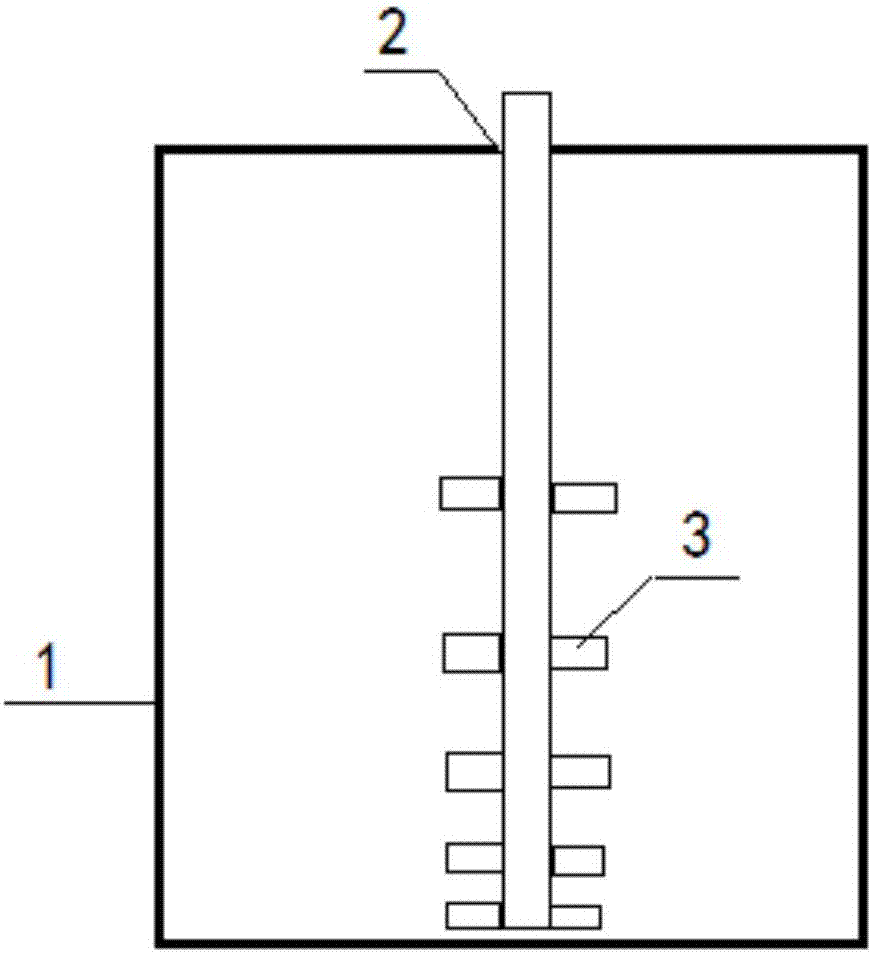

[0034] Use pentamethylol melamine as raw material to synthesize butylated amino resin:

[0035] (1) According to the mol ratio of pentamethylol melamine: butanol, it is 1: 20 to drop into the butanol of the above-mentioned measurement in the above-mentioned reactor, add 36% hydrochloric acid to adjust the pH value to 3.5, add the above-mentioned pentamethylol melamine Melamine, heating up and regulating temperature is 85 ℃ of stirring (adjusting the reactor stirring frequency converter to 20Hz) to make it dissolve;

[0036] (2) after the completion of the reaction after the complete dissolving of pentamethylene melamine, keep warm for 2h;

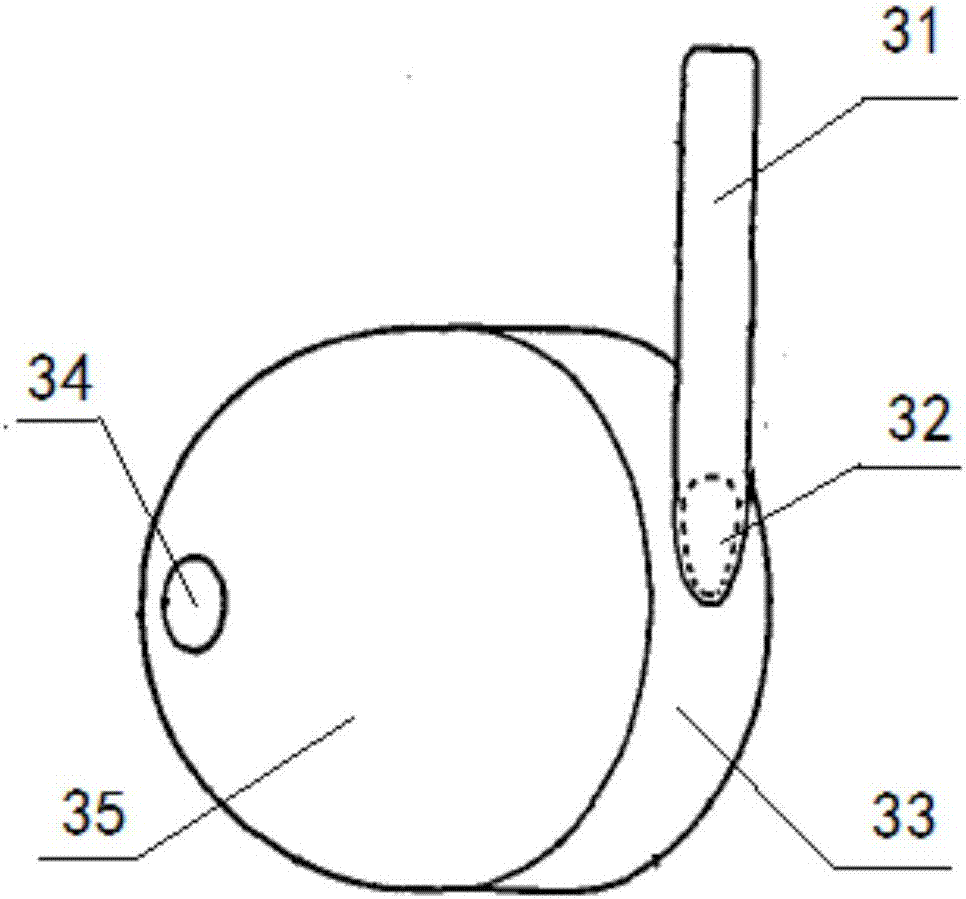

[0037] (3) feed ammonia into the reaction kettle through the above-mentioned ammonia gas feeding device, detect the pH value and adjust the pH to be 9;

[0038] (4) Dealcoholization under normal pressure, the temperature is 100°C, and the time is 30min;

[0039] (5) Start the vacuum pump, control the vacuum degree to 0.08MPa, and the temp...

Embodiment 2

[0044] Step is with embodiment 1, difference is as follows:

[0045] In step (1), the molar ratio of pentamethylol melamine: butanol is 1: 10, the pH value is adjusted to 5, the temperature is raised to 70° C., and the reactor stirring frequency converter is adjusted to 30 Hz;

[0046] In step (2), keep warm for 2h;

[0047] In step (3), the pH value is 8.5;

[0048] In step (4), the temperature is 70°C and the time is 60min;

[0049] In step (5), the temperature is 80°C, the vacuum degree is 0.09MPa, and the dealcoholization and dehydration treatment is carried out for 2 hours;

[0050] In step (6), the added butanol quality is 20% of the pentamethylol melamine quality;

[0051] In step (7), the mass of diatomite added is 0.8% of the mass of pentamethylol melamine.

Embodiment 3

[0053] Step is with embodiment 1, difference is as follows:

[0054] In step (1), the molar ratio of pentamethylol melamine: butanol is 1: 8, the pH value is adjusted to 6, the temperature is raised to 50°C, and the reactor stirring frequency converter is adjusted to 10Hz;

[0055] In step (2), keep warm for 0.5h;

[0056] In step (3), the pH value is 8;

[0057] In step (4), the temperature is 110° C. and the time is 20 minutes;

[0058] In step (5), the temperature is 100°C, the vacuum degree is 0.07MPa, and the dealcoholization and dehydration treatment is 0.5h;

[0059] In step (6), the added butanol quality is 25% of the pentamethylol melamine quality;

[0060] In step (7), the mass of diatomite added is 1% of the mass of pentamethylol melamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com