Polymer material and applications thereof

A technology of polymer materials and pigments, applied in applications, household appliances, sanitary equipment and other directions, can solve problems such as hidden dangers of human safety, inconvenience to clean, poor quality, toxic and harmful, and achieve novel structure, bright and beautiful colors, and simple and easy preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

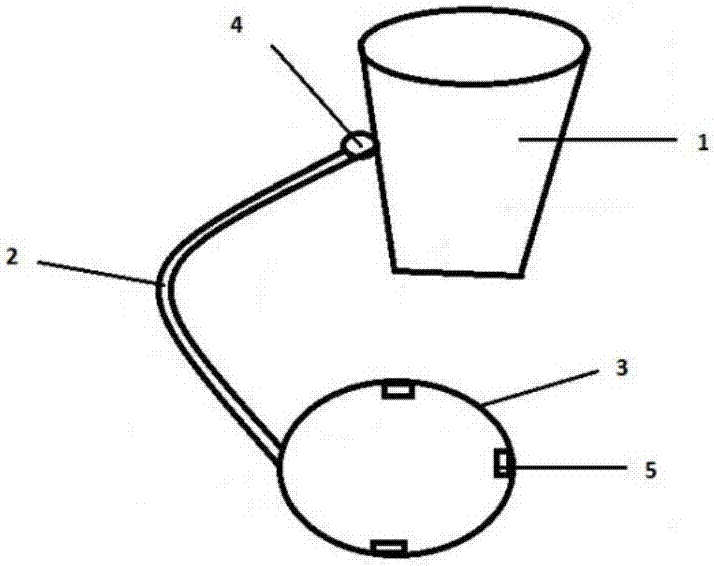

[0029] Such as figure 1 The mouthwash cup shown includes a cup body 1, a cup handle 2 and a base 3, wherein the cup body 1 and the base 3 are connected together by the cup handle 2, and one end of the cup handle 2 is fixedly connected to the base 3, and the cup body 1 The other end of the cup handle 2 is connected with the connecting piece 4, wherein the cup body 1 and the cup handle 2 can be rotated 360 degrees after being connected. Wherein, the base 3 is in the shape of a ring, and a positioning block 5 is provided on the inner edge of the base 3 . When the mouthwash cup is not in use, it can be rotated so that the mouth of the mouth is facing down, so as to prevent dust. The cup body 1 of the mouthwash cup is prepared by one-time injection molding using a polymer material.

Embodiment 2

[0031] The preparation method of cup body in embodiment 1.

[0032] Raw materials: HDPE 4261A 80-120 parts, toughening agent POE 20-30 parts, polyethylene wax 8-15 parts, pigment 1-3 parts, antioxidant 5-8 parts.

[0033] Preparation:

[0034] (1) Preparation of the polymer material: Weigh the raw materials according to the formula ratio, melt and blend at 180°C to obtain the polymer material;

[0035] (2) Melting: melt extruding the polymer blend prepared in step (1), and the melting temperature is 200° C. to form a mold of the polymer blend;

[0036] (3) Extrusion blow molding: the extruder extrudes the tube blank and hangs it in the pre-separated cavity installed directly under the machine head; when the drooping parison reaches the specified length, the mold is closed immediately The die is clamped into the mold to form a mold die; compressed air is injected into the die die to obtain an expanded die having the shape of the mold;

[0037] (4) Pressure-holding molding. A...

Embodiment 3

[0039] The preparation method of cup body in embodiment 1.

[0040] Raw materials: HDPE 4261A 80-120 parts, toughening agent POE 20-30 parts, polyethylene wax 8-15 parts, pigment 1-3 parts, antioxidant 5-8 parts.

[0041] Preparation:

[0042] (1) Preparation of the polymer material: Weigh the raw materials according to the formula ratio, melt and blend at 220°C to obtain the polymer material;

[0043] (2) Melting: melt extruding the polymer blend prepared in step (1), and the melting temperature is 210° C., to form a mold of the polymer blend;

[0044] (3) Extrusion blow molding: the extruder extrudes the tube blank, and hangs it in the pre-separated cavity installed directly under the machine head; when the drooping parison reaches the specified length, it will be closed immediately The die is clamped into the mold to form a mold die; compressed air is injected into the die die to obtain an expanded die having the shape of the mold;

[0045] (4) Pressure-holding molding. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com