Efficient cleaning method of spinneret special for dry-spraying and wet-spinning of polyacrylonitrile-based carbon fiber

A polyacrylonitrile-based carbon fiber, dry-jet wet spinning technology, applied in the direction of spinneret assemblies, textiles and papermaking, etc., can solve the problems of restricting raw silk production output, increasing additional costs, and long cleaning time, so as to improve cleaning Pass rate, reduced drying time, shortened cleaning time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

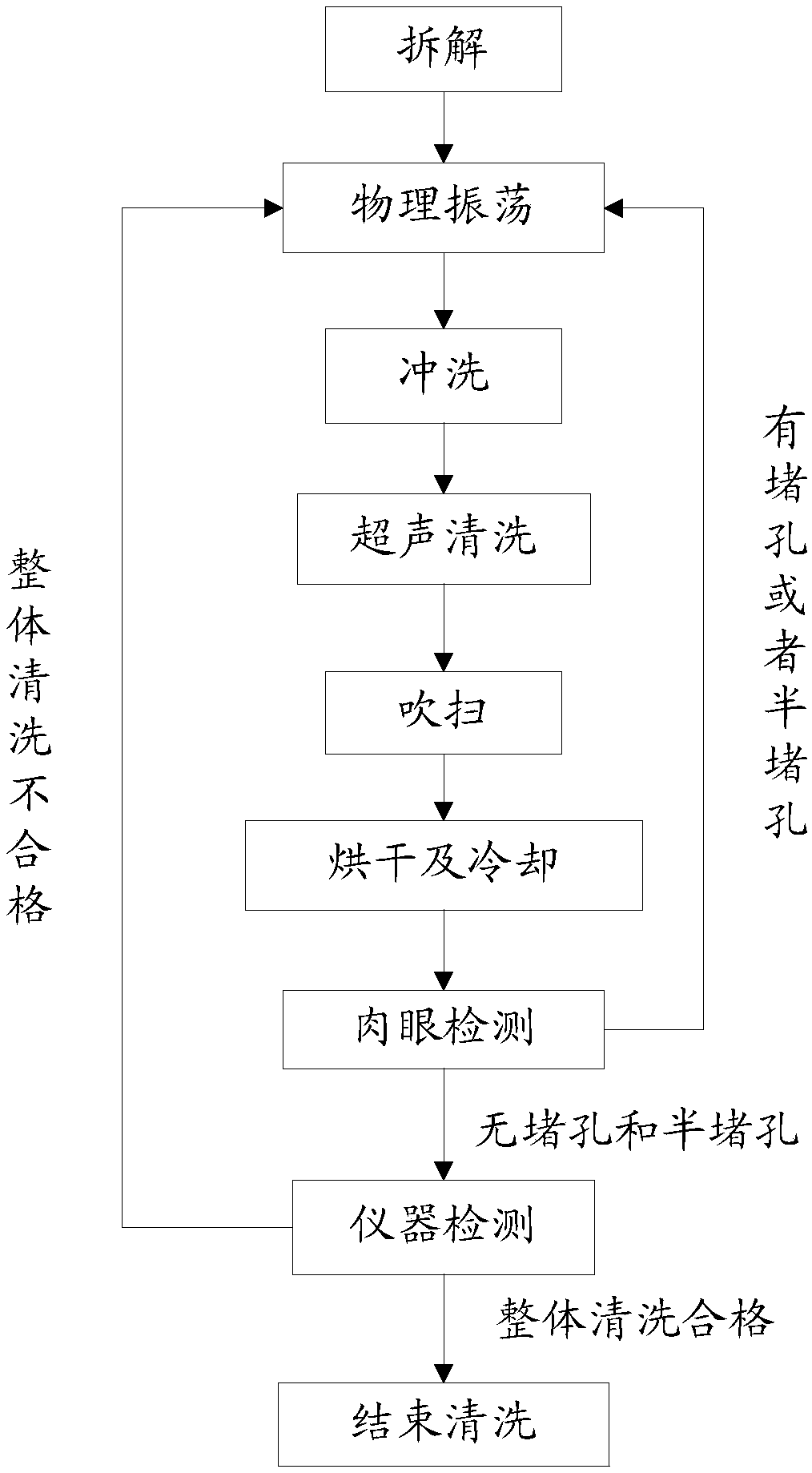

[0031] Please refer to figure 1 , this embodiment provides a high-efficiency cleaning method for a spinneret special for dry-jet wet spinning of polyacrylonitrile-based carbon fibers, including disassembly-physical oscillation-rinsing-ultrasonic cleaning-purging-drying and cooling-visual inspection-instrumental inspection and other steps, the specific process is as follows:

[0032] Disassemble the spinnerets that come down from the site, and remove the spinnerets to be cleaned. During this process, the spinnerets cannot touch any aqueous solution; fix 12 spinnerets in an oscillation device that can vibrate up and down, and the entire oscillation The device is located in a closed container, the cleaning solvent is pure dimethyl sulfoxide, the spinneret has a vertical amplitude of 8 cm, a vibration frequency of 15 times per minute, a cleaning temperature of 80°C, and a cleaning time of 10 hours; take out the spinneret and rinse it with desalted water 5 minutes to ensure that t...

Embodiment 2

[0034] Please refer to figure 1 , this embodiment provides a high-efficiency cleaning method for a spinneret special for dry-jet wet spinning of polyacrylonitrile-based carbon fibers, including disassembly-physical oscillation-rinsing-ultrasonic cleaning-purging-drying and cooling-visual inspection-instrumental inspection and other steps, the specific process is as follows:

[0035] Disassemble the spinnerets that come down from the site, and remove the spinnerets to be cleaned. During this process, the spinnerets cannot touch any aqueous solution; fix 12 spinnerets in an oscillation device that can vibrate up and down, and the entire oscillation The device is located in a closed container, the cleaning solvent is pure dimethyl sulfoxide, the spinneret has a vertical amplitude of 5 cm, a vibration frequency of 10 times per minute, a cleaning temperature of 80°C, and a cleaning time of 8 hours; take out the spinneret and rinse it with desalted water 5 minutes to ensure that th...

Embodiment 3

[0037] Please refer to figure 1 , this embodiment provides a high-efficiency cleaning method for a spinneret special for dry-jet wet spinning of polyacrylonitrile-based carbon fibers, including disassembly-physical oscillation-rinsing-ultrasonic cleaning-purging-drying and cooling-visual inspection-instrumental inspection and other steps, the specific process is as follows:

[0038] Disassemble the spinnerets that come down from the site, and remove the spinnerets to be cleaned. During this process, the spinnerets cannot touch any aqueous solution; fix 12 spinnerets in an oscillation device that can vibrate up and down, and the entire oscillation The device is located in a closed container, the cleaning solvent is pure dimethyl sulfoxide, the spinneret has a vertical amplitude of 15 cm, a vibration frequency of 30 times per minute, a cleaning temperature of 60°C, and a cleaning time of 12 hours; take out the spinneret and rinse it with desalted water 8 minutes to ensure that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com