Fabricated road construction method

A road construction and assembly technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems that roads cannot be put into use quickly, sand and gravel materials are not easy to obtain, and construction time is limited, so as to achieve simple and rapid assembly and reduce construction costs. Time cost, the effect of reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

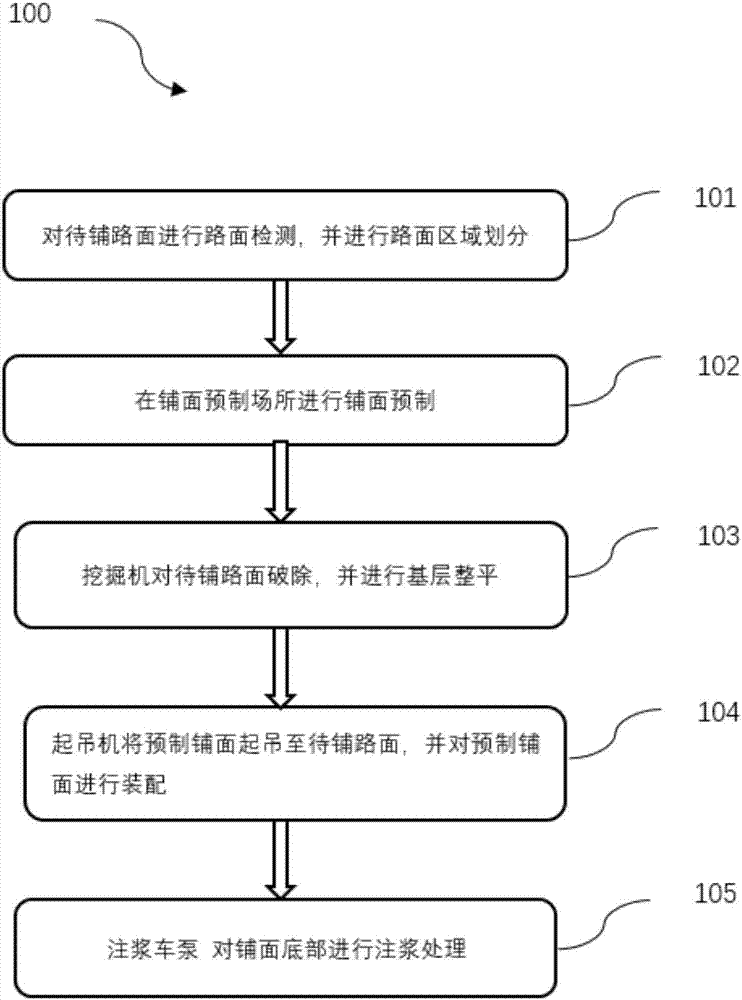

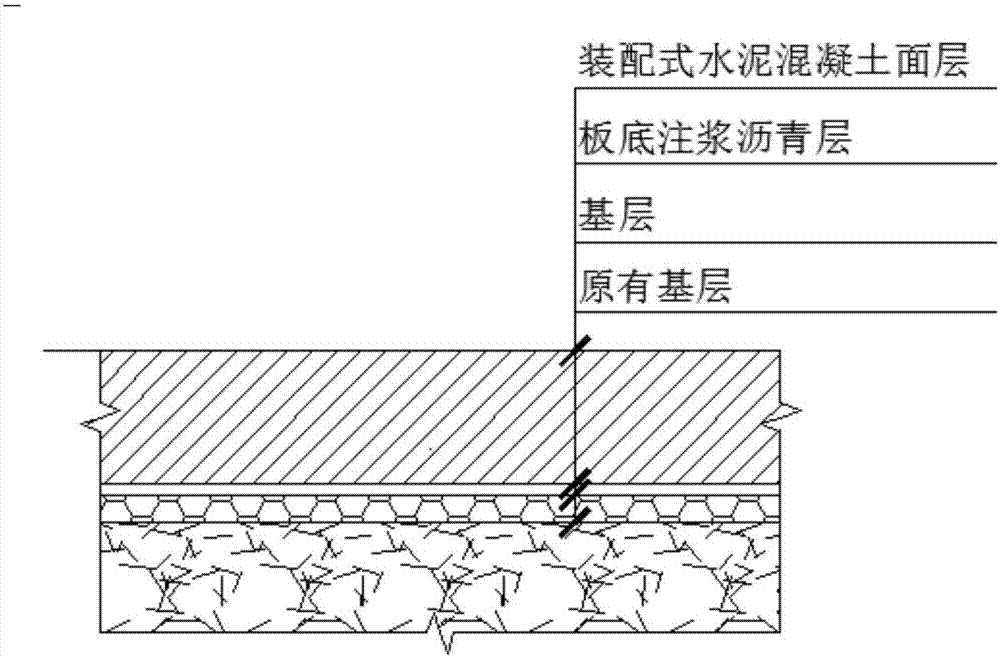

[0050] Such as figure 1 As shown, the embodiment of the present invention provides a prefabricated road construction method 100, which includes the following steps, and is characterized in that: 101 performing road surface detection on the surface to be paved and dividing the road surface area; 102 performing pavement prefabrication at the prefabrication site; The 104 crane lifts the prefabricated pavement to the paved surface and assembles the prefabricated pavement; the 105 grouting truck pump grouts the bottom of the pavement; figure 2 Shown is a schematic diagram of the fabricated pavement structure after construction by this construction method.

[0051] Firstly, the thickness distribution of the surface to be paved is detected, and the thickness of the surface layer of the surface to be paved is collected by ultrasonic array non-destructive testing equipment; in this embodiment, the ultrasonic array testing equipment adopts PL200-PE equipment, which uses point scanning ...

no. 2 example

[0059] This embodiment relates to a prefabricated road, which is obtained through the construction method in the first embodiment.

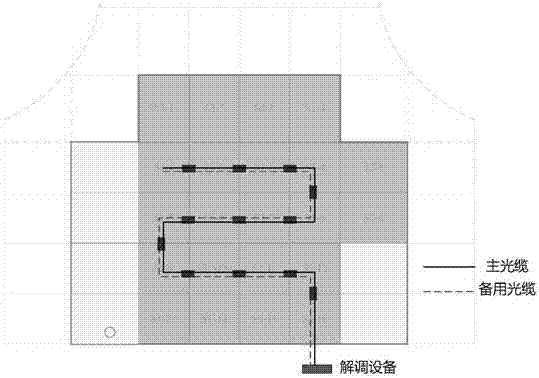

[0060] The road obtained by the construction method of the first embodiment, because the pavement is prefabricated in the special site for pavement prefabrication, when the road is repaired and laid, only the base layer of the paved road needs to be destroyed and leveled, which is different from ordinary Compared with the road construction method, the time for pouring, flattening and forming of the road surface is saved, and the time for road repair is greatly shortened. Especially for the maintenance of urban traffic core roads and airport roads, the allowable repair and laying time is limited. The road is formally based on this and offers the possibility to repair and pave the road in a short period of time. In addition, sensor elements are buried at the pavement level, which can sense the actual usage status of the pavement and passing vehicle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com