Novel oil tube screw-on machine

A new type of oil pipe technology, applied in the field of new oil pipe screwing machines and electric tools, can solve the problems of shifting out, difficult operation, and easy damage to equipment, and achieve the effect of large speed ratio, simple operation, and not easy to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

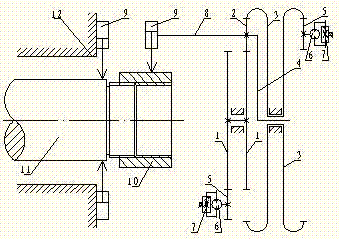

[0008] as attached figure 1 As shown, the planetary gear train of the present invention is formed by the sun gear 1 , the planetary gear 2 , the sun gear 3 and the member 4 . One of the hydraulic motors 6 meshes with the center wheel 1 through one of the gears 5; the other hydraulic motor 6 meshes with the sun gear 3 through the other gear 5, so the power of the two hydraulic motors 6 is respectively The input is on the center wheel 1 and the sun wheel 3, and the flows of the two hydraulic motors 6 are respectively controlled by the two proportional speed regulating valves 7, which forms the power input system of the present invention. In order to balance the centrifugal inertial force generated by the planetary gears and reduce the force of the planetary gears, six planetary gears 2 are symmetrically distributed between the center gear 1 and the sun gear 3 . Each end of the six connecting shafts 7 is respectively fixed to the central shafts of the six planetary wheels 2; eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com