Vertical deceleration direct current permanent magnet motor

A permanent magnet motor, vertical technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of heavy weight, large torque, small torque, etc., and achieve the effect of reducing production cost, low noise, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

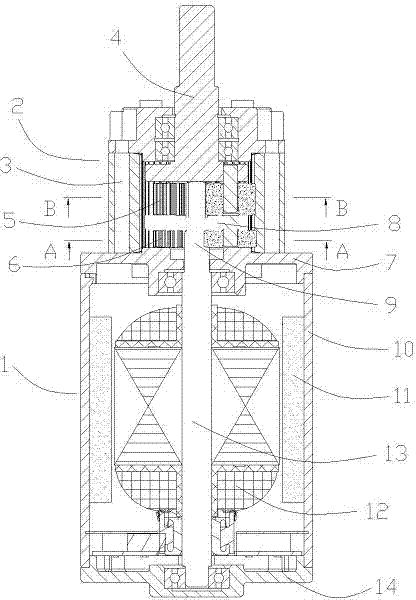

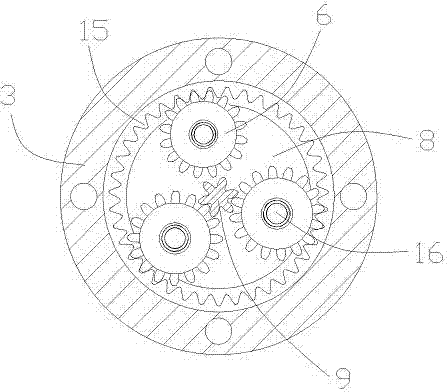

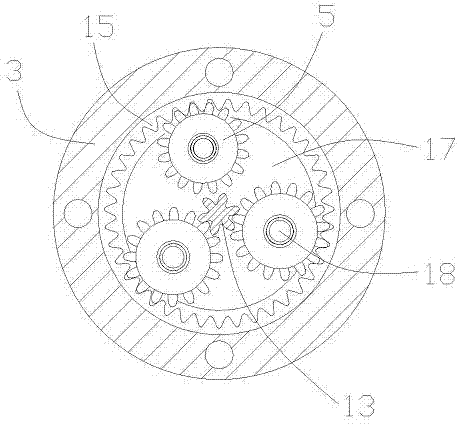

[0025] A kind of vertical deceleration DC permanent magnet motor of this embodiment, such as figure 1 As shown, it includes motor 1 and gearbox 2 which are integrally arranged. The motor is a vertical DC permanent magnet motor. The gearbox is integrally arranged on the motor and linked with the output shaft of the motor. 4. The front end of the output shaft of the gearbox is an external hexagonal structure, and the output shaft of the gearbox is parallel to the output shaft of the motor. The motor includes a housing, the housing is composed of a front end cover 7, a motor barrel 10 and a rear end cover 14, a rotating shaft 13 is arranged in the housing, one end of the rotating shaft is arranged on the rear end cover through a bearing, and the other end of the rotating shaft passes through the front end cover and Stretch in the reduction box, this end of the rotating shaft is also connected with the front end cover by a bearing, and the part of the rotating shaft front end stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com