Motorcycle frame indoor multi-axis fatigue test method under orthogonal force control

A test method, motorcycle technology, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of complex structure of the test system, difficult iterative convergence, excitation channel coupling, etc., achieve high simulation accuracy, meet Structural degrees of freedom and motion decoupling, efficient and accurate assessment of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

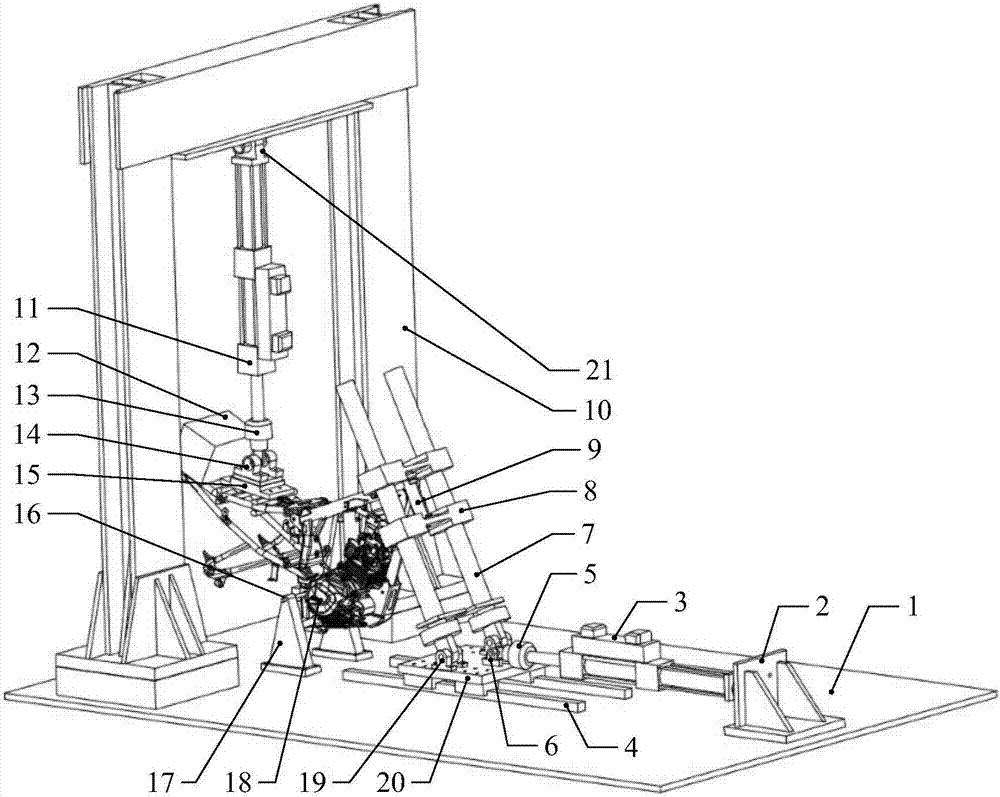

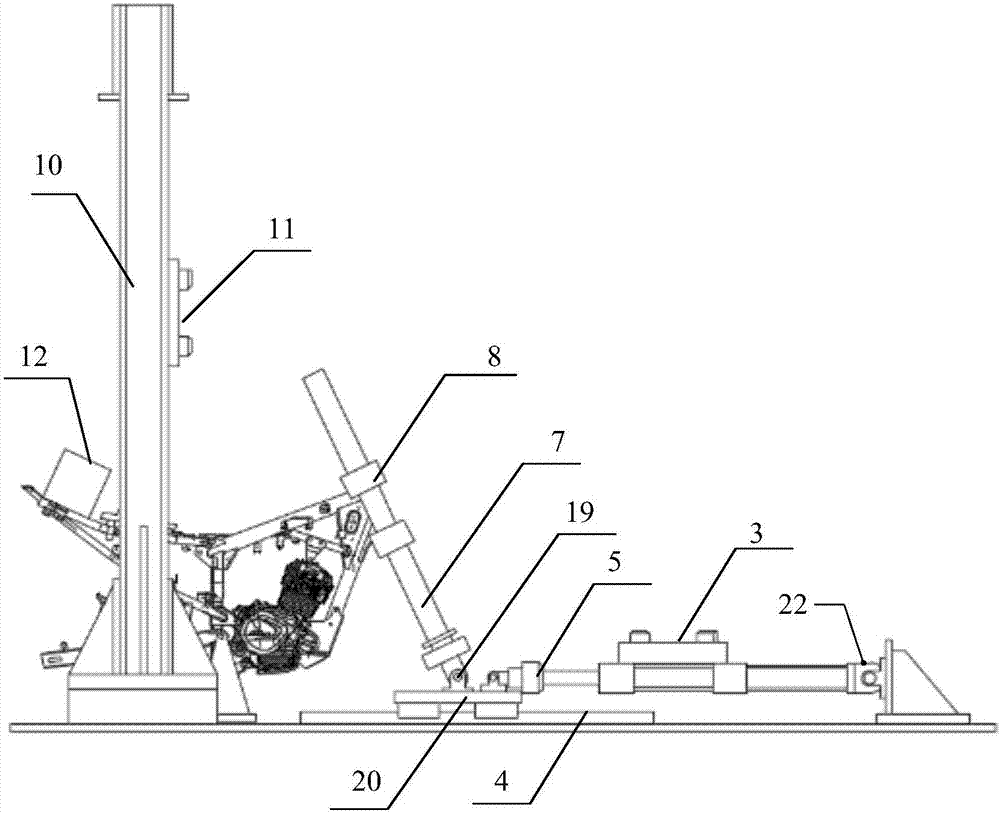

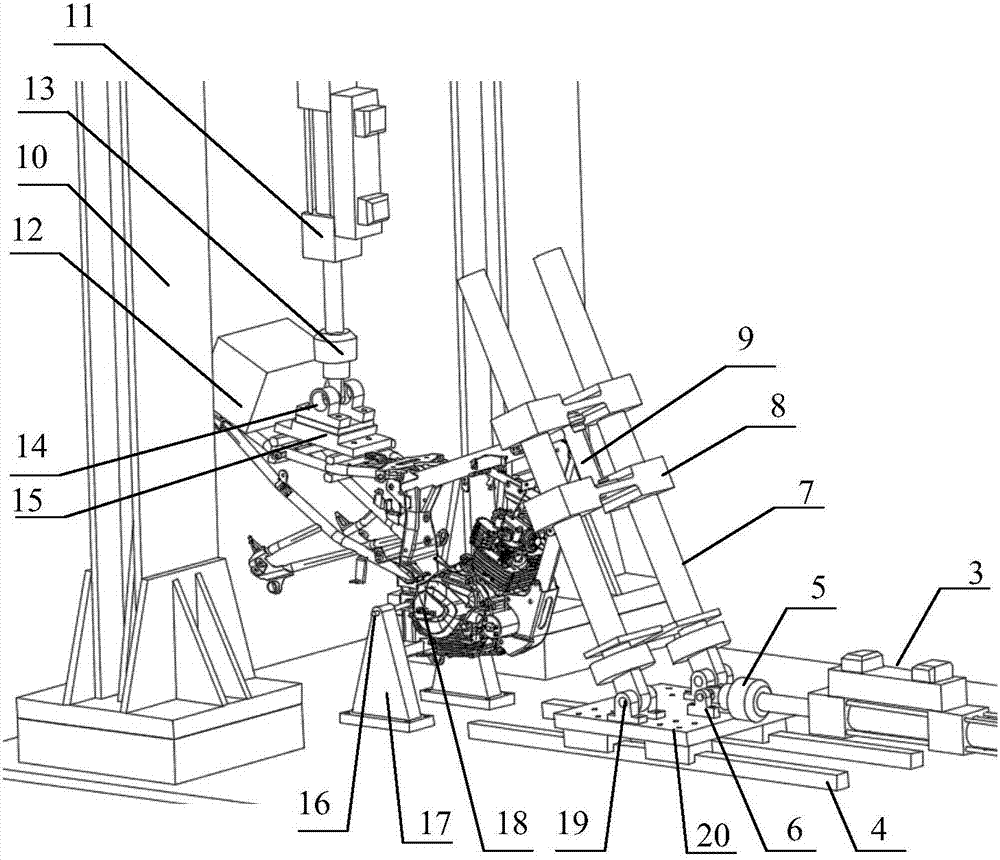

[0052] Specific implementation mode 1. Combination Figure 1 to Figure 6 This embodiment will be described. A multi-axis fatigue test method of a motorcycle frame controlled by a normal force, a set of test system is adopted in the method, the test system includes a mounting base 1, a rear support of a horizontal vibration exciter 2, a horizontal vibration exciter 3, Guide rail 4, horizontal vibration exciter force sensor 5, plane hinge I6, front bracket riser 7, front bracket splint 8, gantry 10, vertical vibration exciter 11, vertical vibration exciter force sensor 13, plane hinge II 14, connecting fixture 15. Intermediate shaft 16, intermediate shaft fixing support 17, engine assembly 18, plane hinge III19, guide rail slide plate 20, plane hinge IV21 and plane hinge V22;

[0053] The rear support 2, guide rail 4, gantry 10, and intermediate shaft fixing support 17 of the horizontal vibration exciter are respectively fixed on the installation base 1; I6 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com