Method for evaluating sensory organ quality of tobacco through heating burning-free method

A heat-not-burn, sensory quality technology, applied in measuring devices, material thermal analysis, instruments, etc., can solve the problem of heat-not-burn without an evaluation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

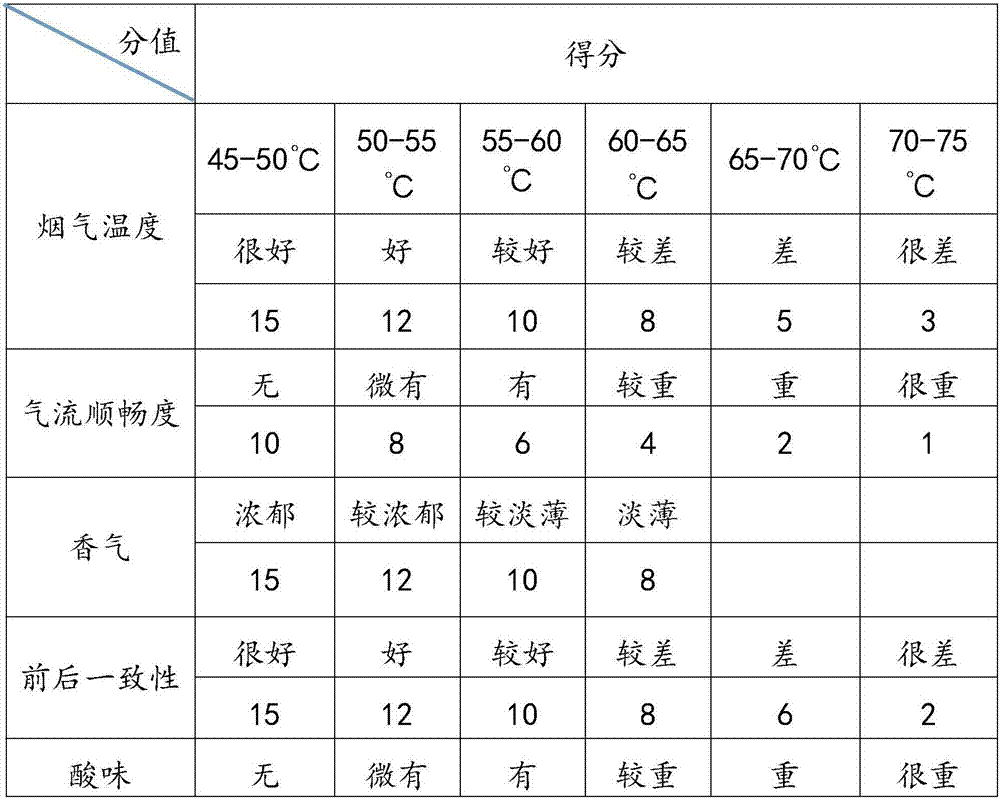

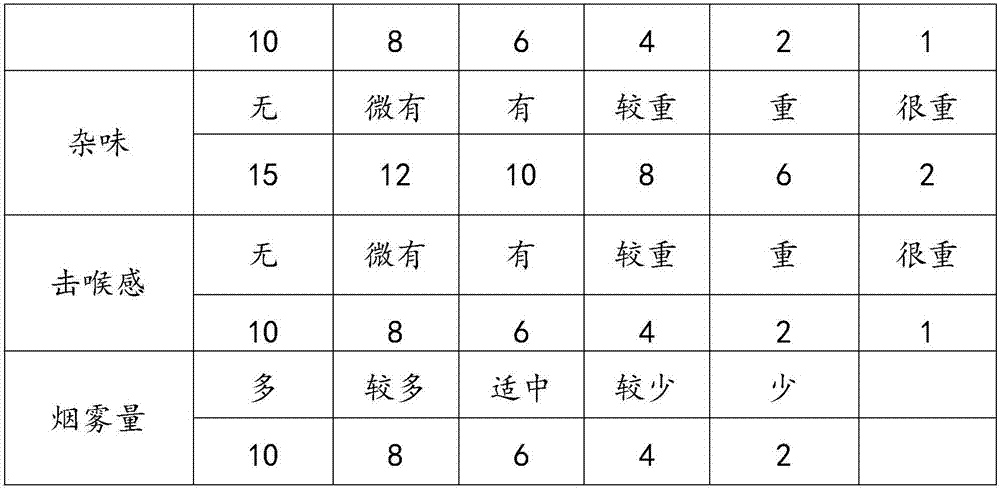

[0051] Use A heat-not-burn smoking set, choose cigarette products produced by a well-known domestic manufacturer A, select an appropriate amount of shredded tobacco and place it evenly in the distillation area, and start smoking after constant temperature. Set up 7 appraisers, adopt the overall cycle evaluation method, and the duration of single-puff puffing is 2±0.02S; puffing frequency: measure 5 puffs in a row, and the puffing frequency should be one puff every 10S; Score and record all rating indicators except flue gas temperature.

[0052] Among them, the smoke temperature detection method: test with a smoking machine, the smoking set is fixed with a holder, the tobacco products are placed in the smoking set, and the temperature probe is set at the source of the smoke; the standard conditions of the smoking machine test are: negative pressure of the smoking machine, and the setting parameters are 250Pa, suction 2S; the entire airflow path between the mouthpiece and the su...

Embodiment 2

[0057] Use the smoking set of A family, choose the thin sheet products produced by Marlboro, place the products in the distillation area, and start smoking after constant temperature. Set up 7 appraisers, adopt the overall cycle evaluation method, the duration of single puffing is: 2±0.02S; suction frequency: measure 5 puffs in a row, and the puffing frequency should be one puff every 10S; All rating indicators except flue gas temperature are scored and recorded.

[0058] Among them, the smoke temperature detection method: test with a smoking machine, the smoking set is fixed with a holder, the tobacco products are placed in the smoking set, and the temperature probe is set at the source of the smoke; the standard conditions of the smoking machine test are: negative pressure of the smoking machine, parameters of the smoking machine Set to 250Pa, suction 2S; the entire airflow path between the mouthpiece and the suction machine should have as little resistance as possible, and ...

Embodiment 2

[0064] The SD value in Example 2 is smaller than that in Example 1. On the one hand, it shows that the smoking consistency of the smokers in Example 2 is better, and it also shows that the comprehensive quality of tobacco in Example 2 is more stable than that in Example 1. , can be used as a preferred tobacco product. In order to overcome the subjective influence as much as possible, smokers with rich smoking experience and good smoking consistency should be selected to evaluate the sensory quality of tobacco.

[0065] The tobacco sensory quality evaluation method under the heat-not-burn method achieved above, through scientifically setting evaluation indicators and evaluation methods, makes the smoke evaluation conclusions of tobacco after heat-not-burning highly targeted, objective, scientific, practical and consistent it is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com