Absorbing product

A technology for absorbent products and absorbent layers, which is applied in the field of hygiene products, and can solve the problems of easy running out, displacement, falling, and easy falling of superabsorbent resins.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

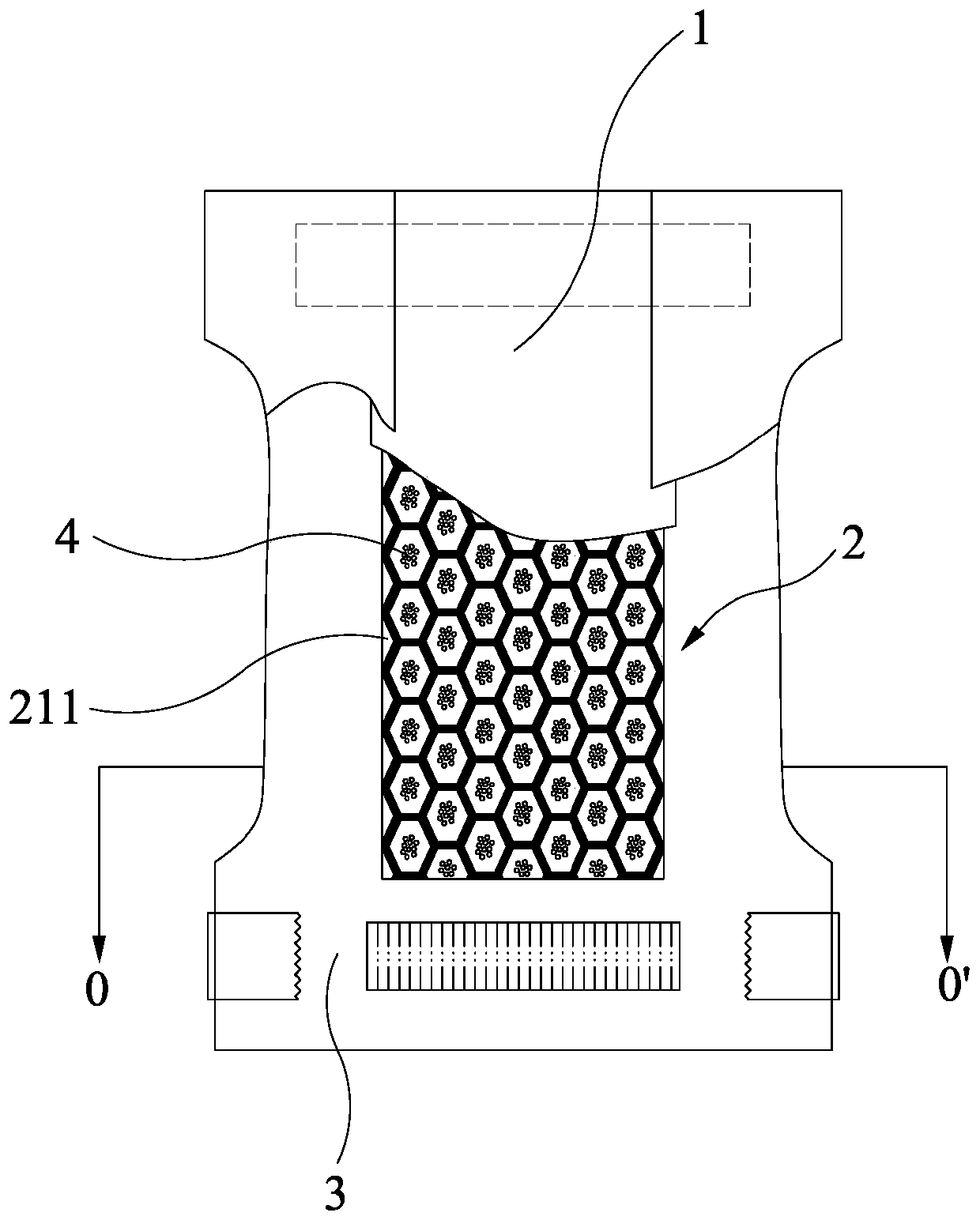

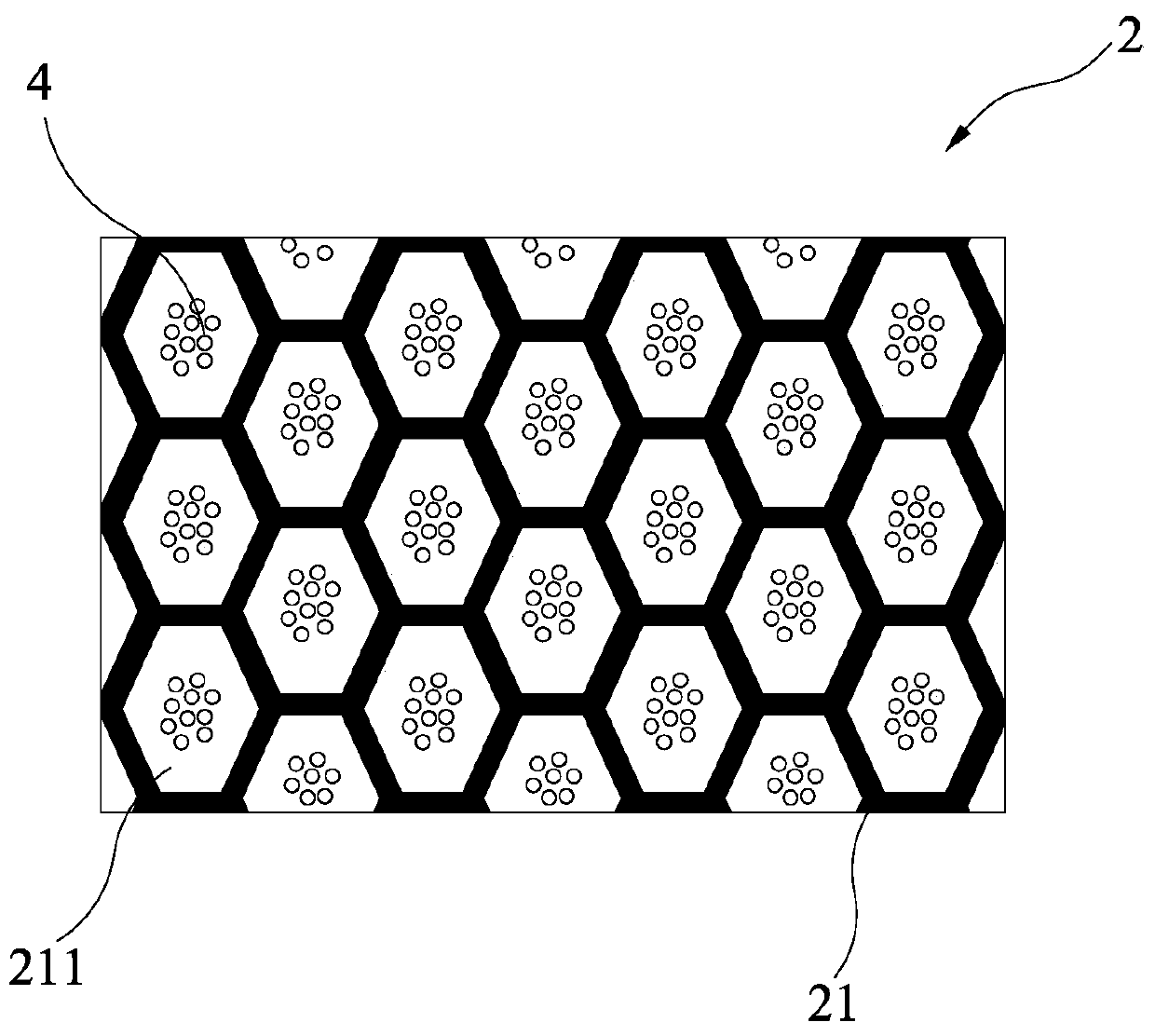

[0040] like Figure 1 to Figure 2 As shown, the perforated film 21 of the absorbent article is located between the liquid permeable surface layer 1 and the absorbent core 22, the openings 211 of the perforated film 21 are funnel-shaped, and the thickness of the perforated film 21 is 2 mm, so The volume of the single opening 211 is 58 mm 3 , the funnel-shaped opening 211 has a super absorbent resin 4 therein.

[0041] like Figure 3 to Figure 4 As shown, the absorbent article is compounded layer by layer, and the superabsorbent resin 4 is added to the absorbent layer 2 by in-line addition. During the adding process, since the perforated film 21 has openings 211, the high When the water absorbent resin 4 reaches the surface of the perforated film 21, it will roll down into the openings 211 of the perforated film 21. Since the perforated film 21 has a large thickness and a volume of the openings 211, it provides a certain amount of storage for the superabsorbent resin 4. spac...

Embodiment 2

[0044] like Figure 3 to Figure 4 As shown, the perforated film 21 of the absorbent article is located between the two layers of absorbent cores 221 and 222, the openings 211 of the perforated film 21 are funnel-shaped, the thickness of the perforated film 21 is 3.8 mm, and the The volume of a single opening 211 is 75 mm 3 , the funnel-shaped opening 211 has a super absorbent resin 4 therein.

[0045] During the use of this embodiment, since the perforated film 21 is located between the two layers of absorbent cores 221 and 222, the upper absorbent core 221 is relatively flat and is in contact with the liquid-permeable surface layer 1, so that the liquid-permeable surface layer 1 is more flat. , so that the overall touch of the absorbent article is softer and more comfortable. At the same time, after passing through the liquid permeable surface layer 1, the bodily fluid will be quickly absorbed by the upper absorbent core 221, and be guided to the perforated film 21 and the...

Embodiment 3

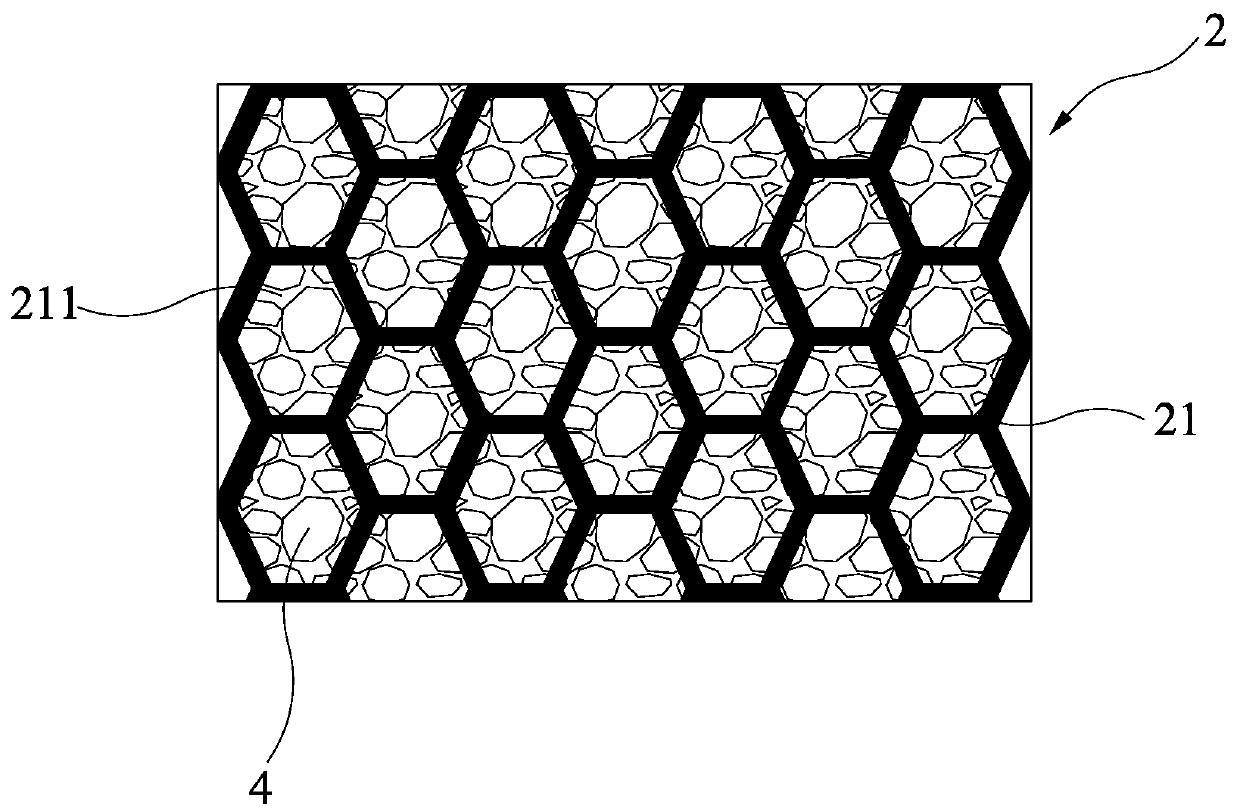

[0047] like Figure 3 to Figure 4 As shown, the perforated film 21 of the absorbent article is also provided with small holes 212a, and at least one small hole 212a is nested at the bottom of the openings 211 of the perforated film 21, and the openings of the perforated film 21 211 is stepped, the thickness of the perforated film 21 is 4.0 mm, and the volume of the single opening 211 is 82 mm 3 , the stepped opening 211 has a super absorbent resin 4 therein.

[0048] During the use of this embodiment, due to the large size and high thickness of the openings 211 of the perforated film 21, problems such as hole pattern collapse, deformation, winding or difficulty in maintaining the hole pattern in production are easily caused, and at least one small hole 212a is nested at the bottom of the opening 211 of the perforated film 21, which can increase the stiffness of the perforated film 21 and help to maintain the hole shape. At the same time, because the size of the openings 211...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com