Continuous timber stacking system

A wood and stacking technology, applied in the field of continuous wood stacking system and stacker, can solve the problems of low degree of automation, and achieve the effect of high degree of automation, reasonable design and simple combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

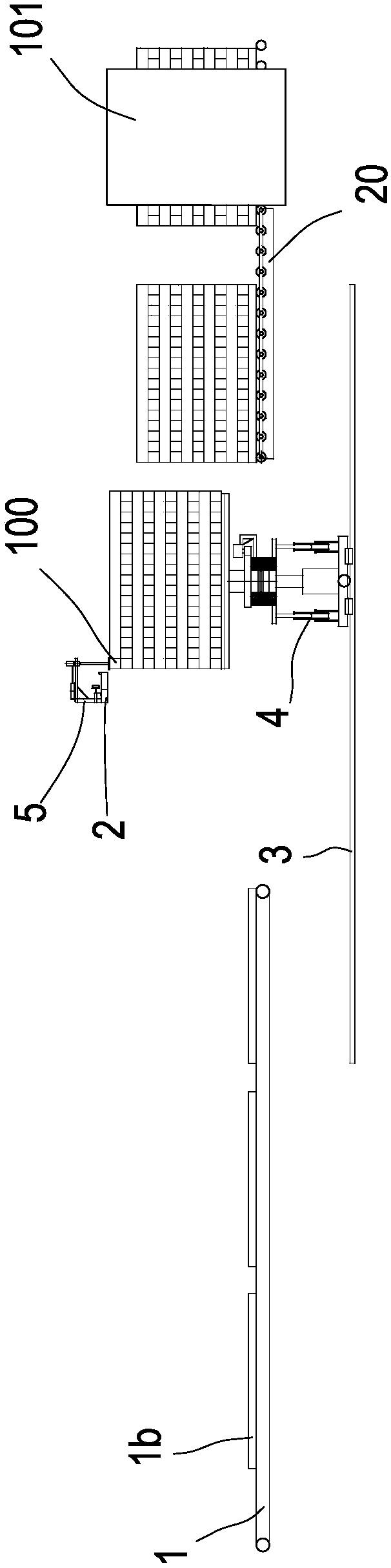

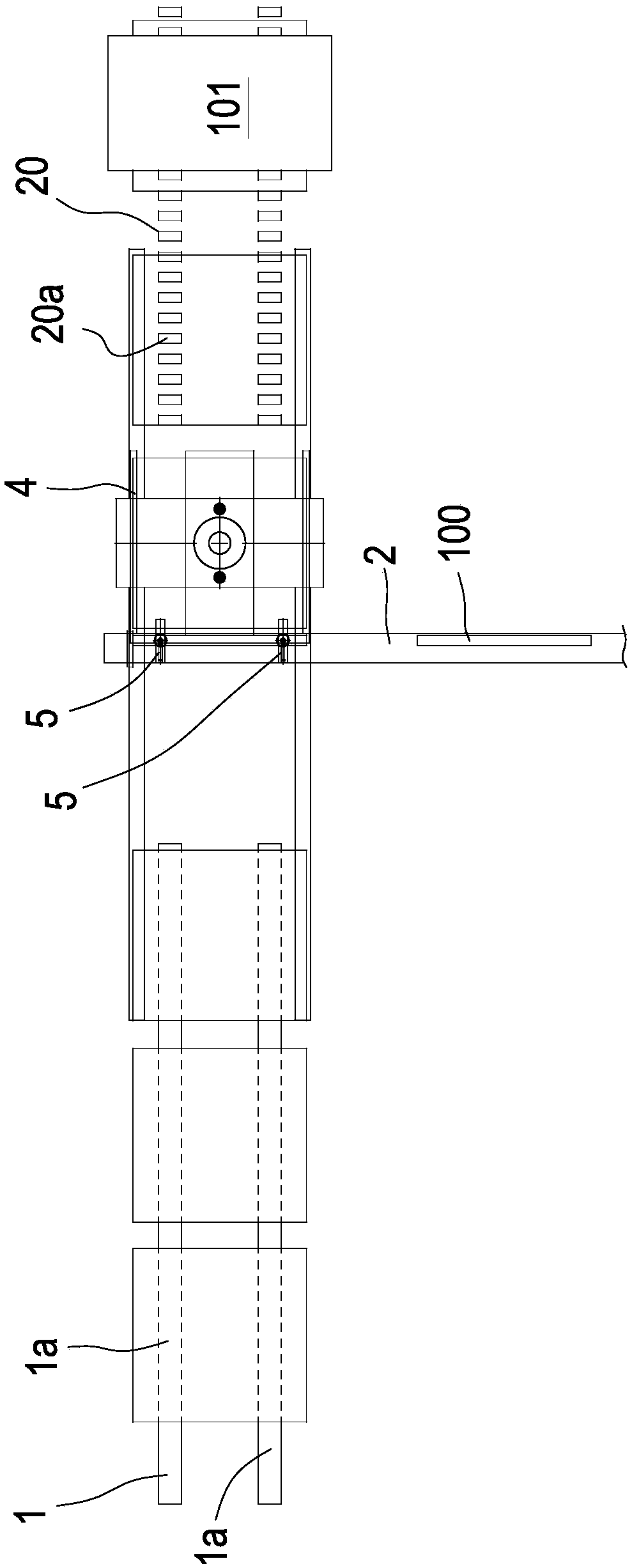

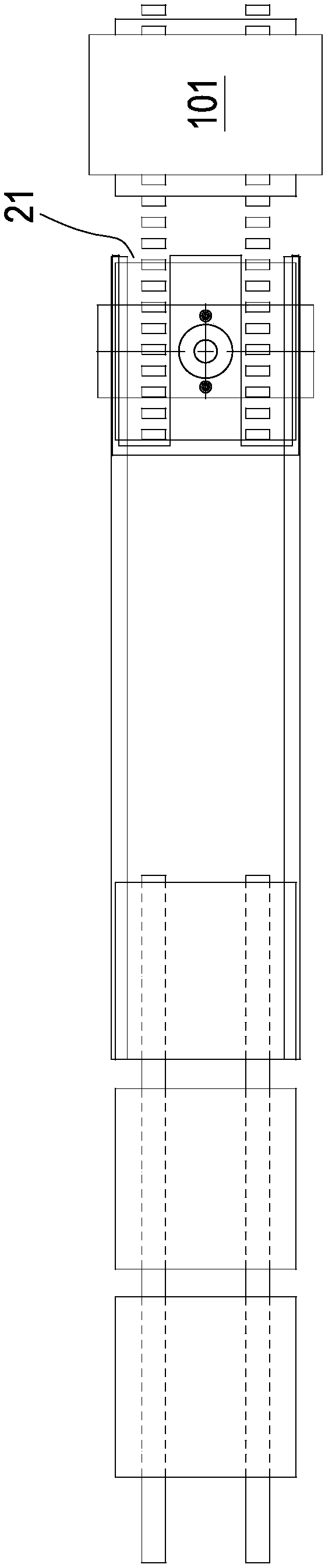

[0039] Such as figure 1 and figure 2 As shown, a continuous timber stacking system includes a pallet conveyor belt 1, a timber conveyor belt 2 and a slide rail 3, and also includes a stacker 4 connecting the slide rail 3 and the pallet conveyor belt 1, and connecting the timber conveyor belt 2 The stacking machine 5 also includes a packing conveyor belt 20, the packing conveyor belt 20 is connected to the packing machine 101, and the stacker 4 is located between the pallet conveyor belt 1 and the packing conveyor belt 20.

[0040] Such as Figure 7 As shown, the stacker 4 includes a stacker base 6 that is slidably connected to the slide rail 3, and the stacker base 6 is provided with a swivel seat 7 that can rotate 360°. A rotating seat lifting mechanism 8 capable of reciprocating vertical lifting is provided on the top, and the rotating seat lifting mechanism 8 is connected to the rotating seat 7 .

[0041] The rotating base lifting mechanism 8 can adopt a screw rod or an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com