Fixing device for automatic delivery system trolley for building

A technology of fixing device and driving device, applied in transportation and packaging, elevators, elevators in buildings, etc., can solve the problems of time-consuming consignees, low commuting efficiency, waste of human resources and social resources, etc., to improve the operation Efficiency and efficiency, reduce the cost of express delivery, improve the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

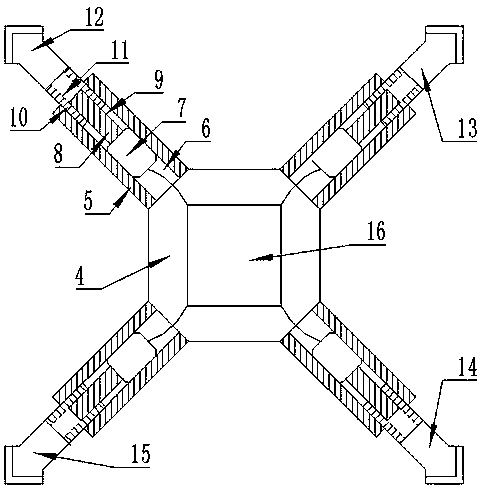

[0034] On the basis of the above embodiments, the control device 16 includes a central processing unit, a sensor signal processing circuit, and a driving circuit, the central processing unit is connected to the input end of the driving circuit, and the output end of the driving circuit is electrically connected to the driving device 7; The sensor 20 is electrically connected to the input end of the sensor signal processing circuit, and the output end of the sensor signal processing circuit is connected to the central processing unit for signal.

[0035] The central processing unit realizes the forward and reverse control of the driving device 7 through the drive circuit, and the central processing unit can know whether the container is firmly clamped through the detection and processing of the pressure sensor 20 and the sensor signal processing circuit.

Embodiment 2

[0037] On the basis of the basic implementation mode or Example 1, the drive device 7 is a linear motor, the moving end of the linear motor is fixedly connected to the fixed claw connector 10, the input end of the linear motor is connected with a linear motor drive circuit, and the linear motor drives The input of the circuit is electrically connected to the control device 16 .

[0038] The control device 16 controls the expansion and contraction of the linear motor through the linear motor driving circuit, and then drives the expansion and contraction of the fixed claw connector 10 to realize loading and unloading of the container.

Embodiment 3

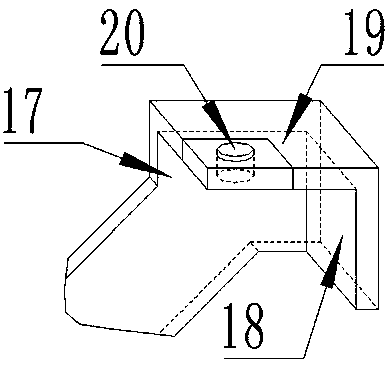

[0040] On the basis of embodiment 1 or embodiment 2, the first baffle plate 18 or the second baffle plate 19 are provided with an electromagnet, and also include an electromagnet drive circuit, the input end of the electromagnet drive circuit is electrically connected with the control device 16, and the electromagnet The output terminal of the driving circuit is electrically connected with the electromagnet.

[0041] When it is necessary to load goods, when the first fixed claw 12, the second fixed claw 13, the third fixed claw 14, and the fourth fixed claw 15 fix the container, the control device 16 starts the electromagnet through the electromagnet drive circuit to realize the alignment of the container. further stabilization. When the goods need to be unloaded, the control device 16 closes the electromagnet through the electromagnet driving circuit, so as to realize the release of the cargo box. In this way, the security of the system can be further improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com