Combined type line cutting device

A compound and tangent technology, applied in the field of sewing machines, can solve the problems of not being able to meet the cutting requirements of multiple cutting knives at the same time, the precision cannot be adjusted, and the cutting precision is low, so as to save installation time, have high fault tolerance and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

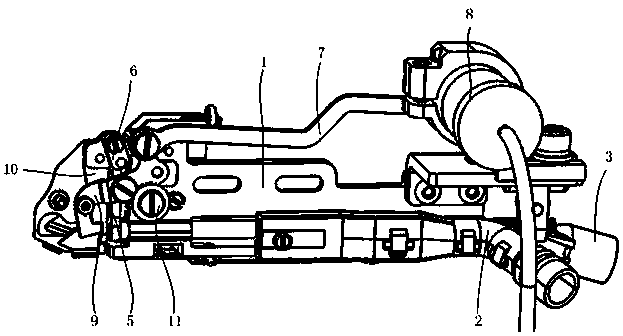

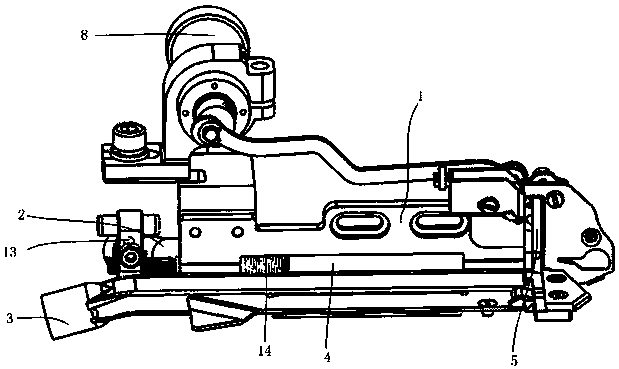

[0023] Embodiment one: if figure 1 , as shown in 2, a composite thread cutting device, including a vertical plate 1, the first air suction channel 2 and the second air suction channel 3 are respectively provided on both sides of the vertical plate 1, and a rotating Shaft 4, one end of the rotating shaft 4 is connected with a first drive motor, and the other end is connected with a chopping knife 5; one side of the vertical plate 1 is provided with a transmission rod 7, and one end of the transmission rod 7 is connected with a second drive The other end of the motor 8 is hinged with a movable air suction knife 9, the movable air suction knife 9 is hinged on the vertical plate 1, and the front end of the vertical plate 1 is also fixedly provided with a fixed air suction knife that cooperates with the movable air suction knife 9. Wind Knife10.

Embodiment 2

[0024] Embodiment two: if figure 1 , as shown in 2, a composite thread cutting device, including a vertical plate 1, the first air suction channel 2 and the second air suction channel 3 are respectively provided on both sides of the vertical plate 1, and a rotating Shaft 4, one end of the rotating shaft 4 is connected with the first drive motor, and the other end is connected with the chopping knife 5, and the vertical plate 1 above the chopping knife 5 is provided with a lattice block 6; one side of the vertical plate 1 A transmission rod 7 is provided, one end of the transmission rod 7 is connected with a second driving motor 8, and the other end is hinged with a movable air suction knife 9, and the movable air suction knife 9 is hinged on the vertical plate 1, and the vertical air suction knife 9 is hinged. The front end of the plate 1 is also fixedly provided with a fixed air suction knife 10 cooperating with the movable air suction knife 9 .

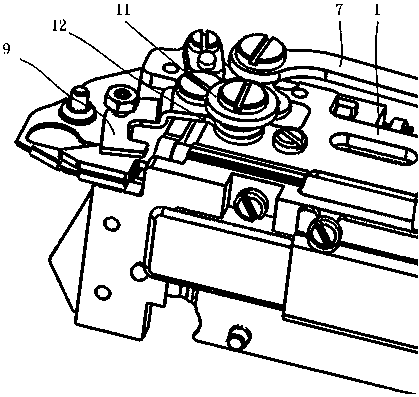

[0025] image 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com