Dyeing and finishing process of acetate fiber interwoven fabric and dyeing agent thereof

A technology of acetate fiber and dyeing agent, which is applied in the treatment of textile materials, dyeing method, liquid/gas/steam textile material processing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

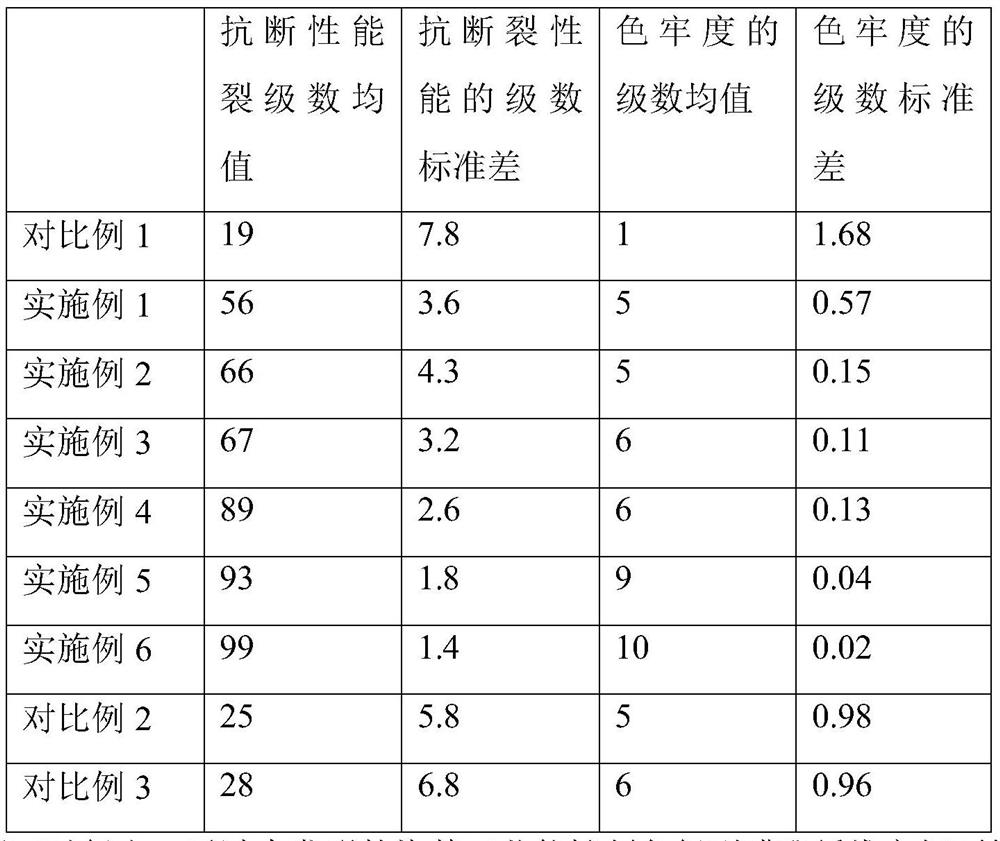

Examples

Embodiment 1

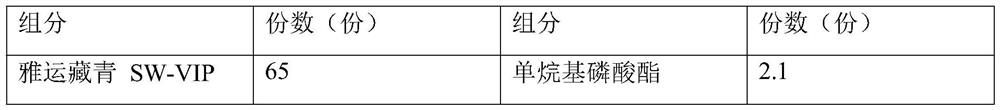

[0031] Reagent components and parts by weight used in the dyeing and finishing process of table 1 embodiment 1

[0032] component Copies (copies) component Copies (copies) Disperse Blue 2BLN 75 Monoalkyl Phosphate 3.1 Sodium lignosulfonate 1.3 Sodium dithionite 3.0

Embodiment 2

[0034] Reagent components and parts by weight used in the dyeing and finishing process of table 2 embodiment 2

[0035] component Copies (copies) component Copies (copies) Disperse Blue 2BLN 70 Monoalkyl Phosphate 3.5 Sodium lignosulfonate 1.1 Sodium dithionite 2.0 Reactive Red M-8B 1.6 / /

Embodiment 3

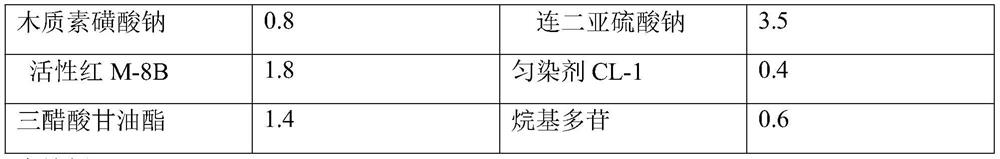

[0037] Reagent components and parts by weight used in the dyeing and finishing process of table 3 embodiment 3

[0038] component Copies (copies) component Copies (copies) Disperse Blue 2BLN 65 Monoalkyl Phosphate 4.1 Sodium lignosulfonate 0.8 Sodium dithionite 2.5 Reactive Red M-8B 1.2 Leveling agent CL-1 0.8 Yayun Tibetan Blue SW-VIP 10 / /

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com