Salt-free dyeing and hand feeling finishing agent for pH value temperature response cotton

A temperature-responsive, salt-free dyeing technology, applied in the field of pH value & amp, can solve the problems of environmental pollution, high salt content in printing and dyeing wastewater, which is difficult to deal with, and achieve the effect of reducing the initial dyeing rate, good hand feeling, and good dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

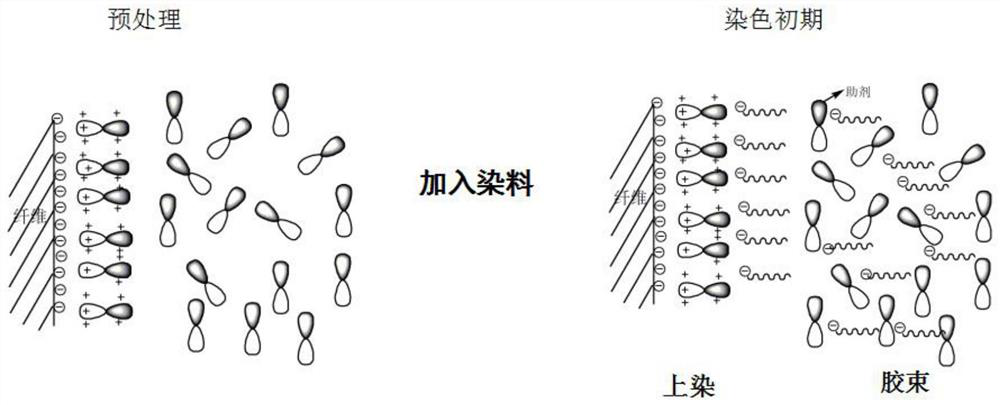

Method used

Image

Examples

Embodiment 1

[0032] S1: Synthesis and preparation of linear double-ended epoxy polyether siloxane:

[0033] Take 30g of glycidyl ether-based allyl epoxy vinyl ether in a four-necked flask, slowly add 5g of terminal hydrogen silicone oil dropwise under stirring, and raise the temperature to 60°C at the same time. After the temperature stabilizes, add dropwise the catalyst chloroplatinic acid / 5 drops of isopropanol solution, heat preservation reaction for 5 hours, after the reaction, remove small molecular oligomers and impurities by vacuum distillation and filtration to obtain linear double-ended epoxy polyether siloxane, wherein the reaction equation is as follows:

[0034]

[0035] S2: Synthesis and preparation of amino block hyperbranched silicone surfactant:

[0036] Take 30g of the linear double-ended epoxy polyether siloxane prepared in the step (1), and 3g of diethylenetriamine respectively into a four-necked flask, stirring continuously, first raising the temperature of the reac...

Embodiment 2

[0048] S1: Synthesis and preparation of linear double-ended epoxy polyether siloxane:

[0049] Take 30-40g of glycidyl ether allyl epoxy ethylene ether in a four-necked flask, slowly add 7g of terminal hydrogen silicone oil dropwise under stirring, and raise the temperature to 70°C at the same time, and add the catalyst platinum chloride dropwise after the temperature is stable 8 drops of acid / isopropanol solution, heat preservation reaction for 7 hours, after the reaction, remove small molecule oligomers and impurities by vacuum distillation and filtration to obtain linear double-ended epoxy polyether siloxane;

[0050] Take 40 g of the linear double-ended epoxy polyether siloxane prepared in the step (1), and 5 g of diethylenetriamine, respectively, and put them into a four-necked flask in turn, and keep stirring. First, raise the temperature of the reaction system to 60° C. Raise the temperature to 80°C and keep the reaction for 8 hours. After the reaction, distill and redu...

Embodiment 3

[0059] conventional staining

[0060]

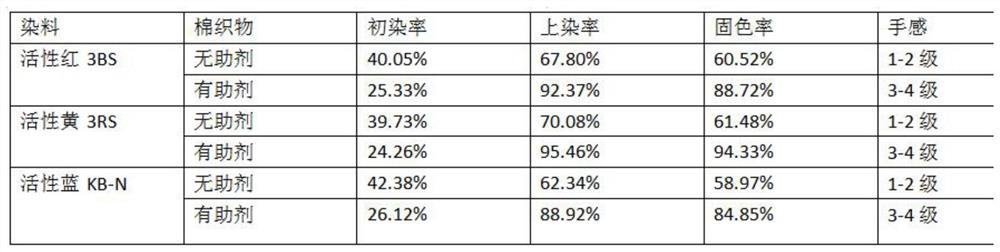

[0061] Comparing Example 1 and Example 2, two groups of pH value & temperature response cottons were applied on two groups of cotton fabrics with salt-free dyeing and hand finishing agent, and then two groups of cotton fabrics were treated with three colors (reactive red 3BS, Reactive Yellow 3RS and Reactive Blue KB-N) are dyed, and compared with initial dyeing rate, dyeing rate, fixation rate and feel after dyeing, draw the pH value & temperature that embodiment one makes Response to cotton with better effect of salt-free dyeing and hand finishing agent;

[0062] image 3 It is the dyeing effect comparison table, according to image 3 For contrast, the cotton fabrics were divided into two groups of control groups, one group used the salt-free dyeing and hand finishing agent for pH value & temperature response cotton prepared in Example 1, one did not add additives, and the two groups of cotton fabrics used three Dyes of different ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com