Rolling bearing weak fault feature early extraction method

A technology for rolling bearings and fault features, which is applied in the field of early extraction of weak fault features of rolling bearings, can solve the problems of difficulty in extracting weak fault features and difficulty in selecting VMD parameters, and achieves the effect of avoiding subjective influence, avoiding design difficulties and simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

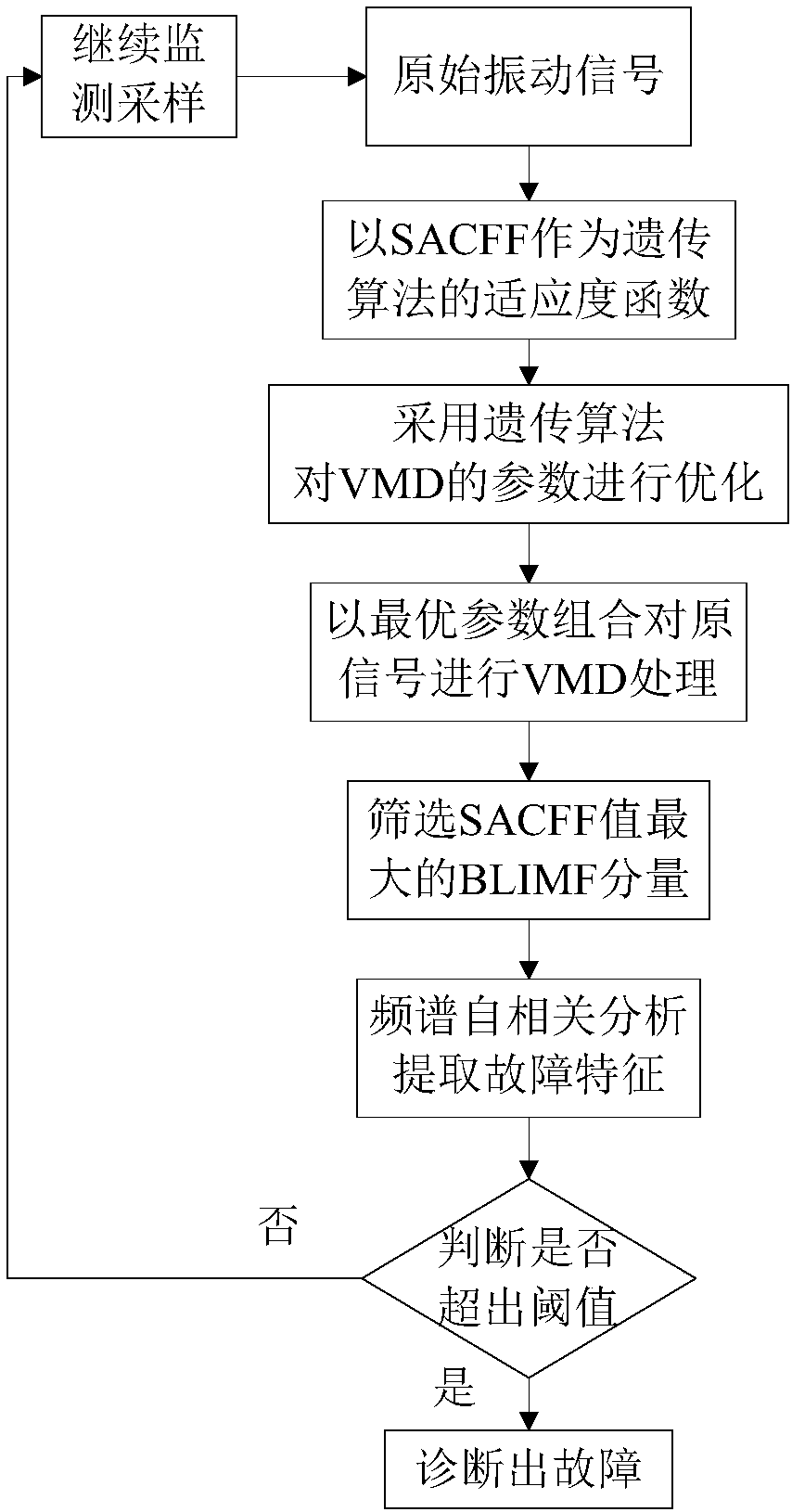

[0044] see figure 1 , the method for early extraction of weak fault features of rolling bearings in this embodiment is carried out according to the following steps:

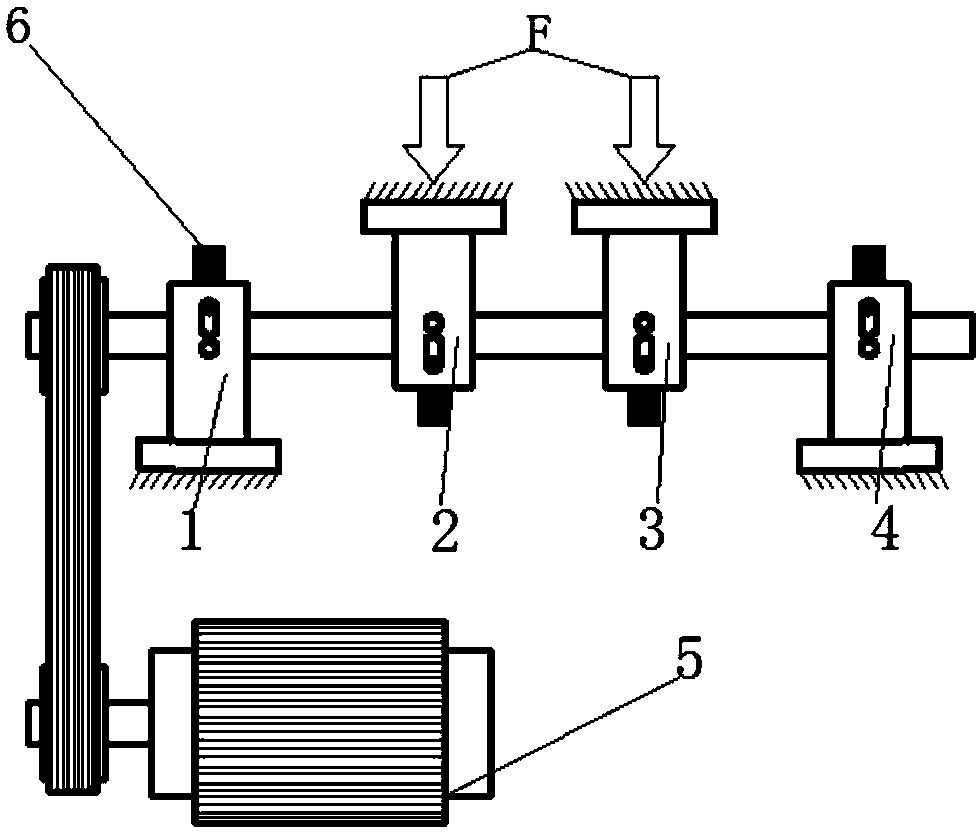

[0045] Step 1. Use the vibration acceleration sensor to pick up the vibration signal of the rolling bearing under operating conditions as the signal x(t) to be analyzed, where t=1, 2, 3, . . . , T, where T is the signal length.

[0046] Step 2. Using the spectral autocorrelation feature factor SACFF of the spectral autocorrelation function as the fitness function, the genetic algorithm is used to optimize the search variational mode decomposition VMD parameters, wherein SACFF refers to Feature Factor of SpectrumAuto-correlation, and VMD refers to Variational Mode Decomposition .

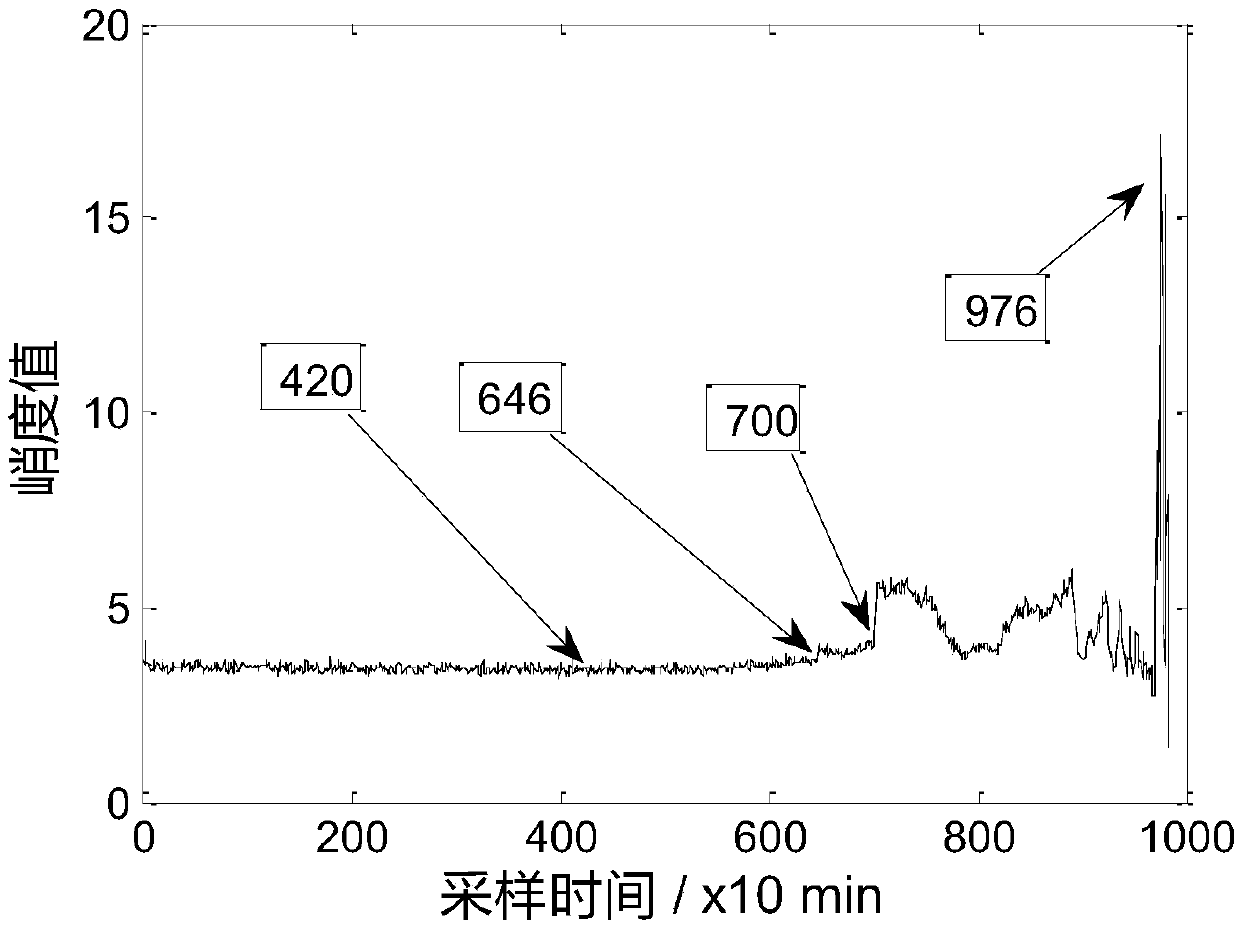

[0047] Step 3. Select the parameter combination (α 0 , K 0 ,τ 0 ) to perform VMD processing on the signal x(t) to be analyzed to obtain K 0 a finite bandwidth eigenmode function BLIMF, and from K 0 In a BLIMF, the component B1 cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com