Testing method for yarn evenness

A technology of evenness and test method, applied in the field of conductive yarn, can solve the problems of high equipment cost, large measurement influence, high requirements, etc., and achieve the effect of accurate and reliable test results and simple mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

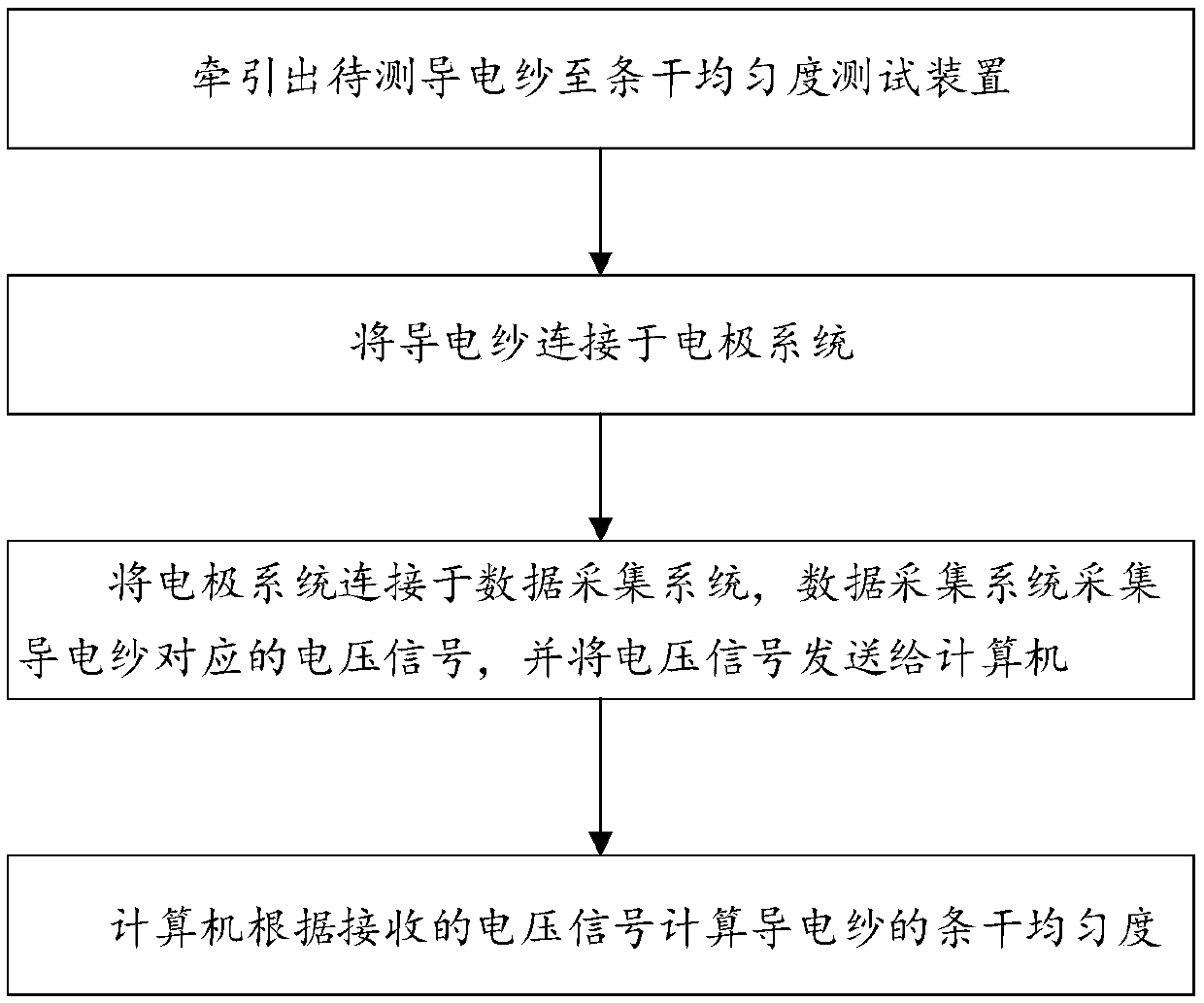

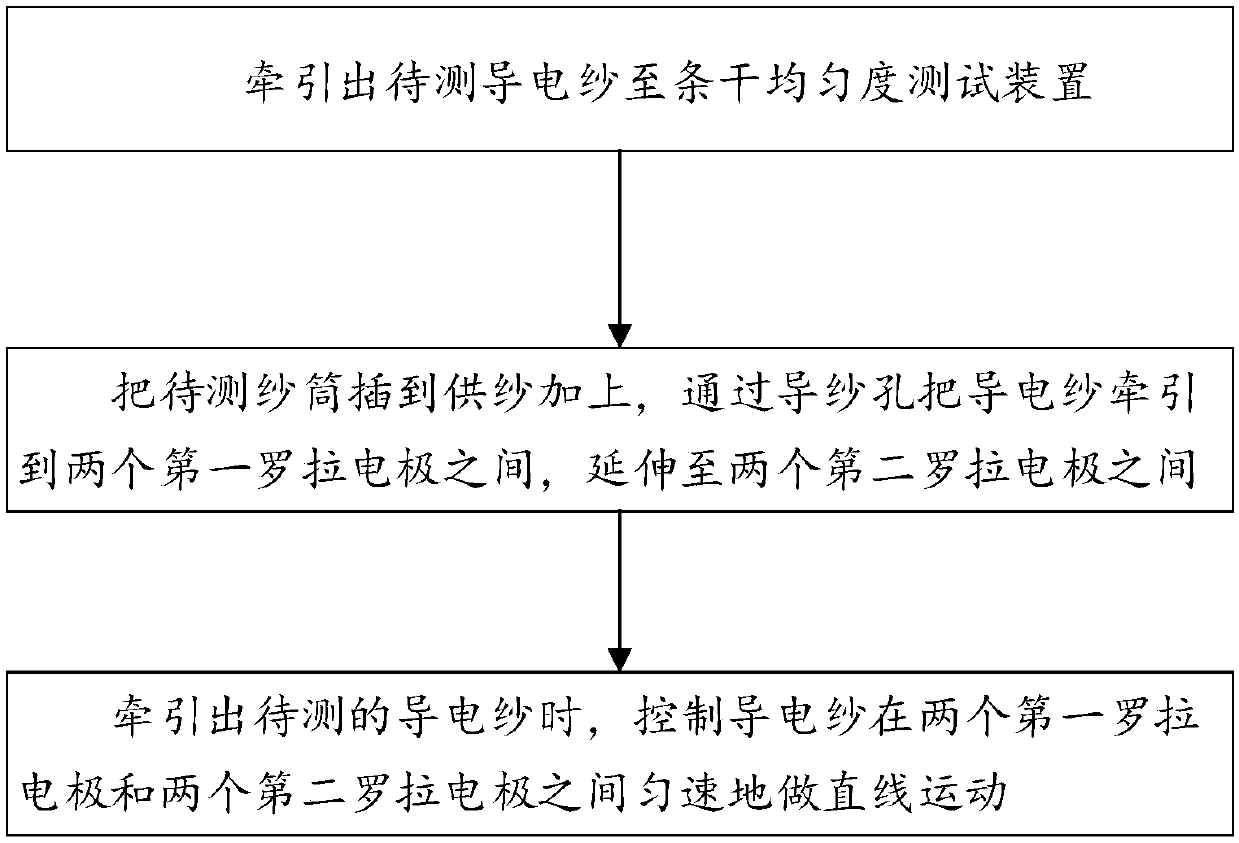

[0032] Please refer to Figure 1-Figure 5 , the present embodiment provides a method for testing evenness of evenness, comprising the following steps:

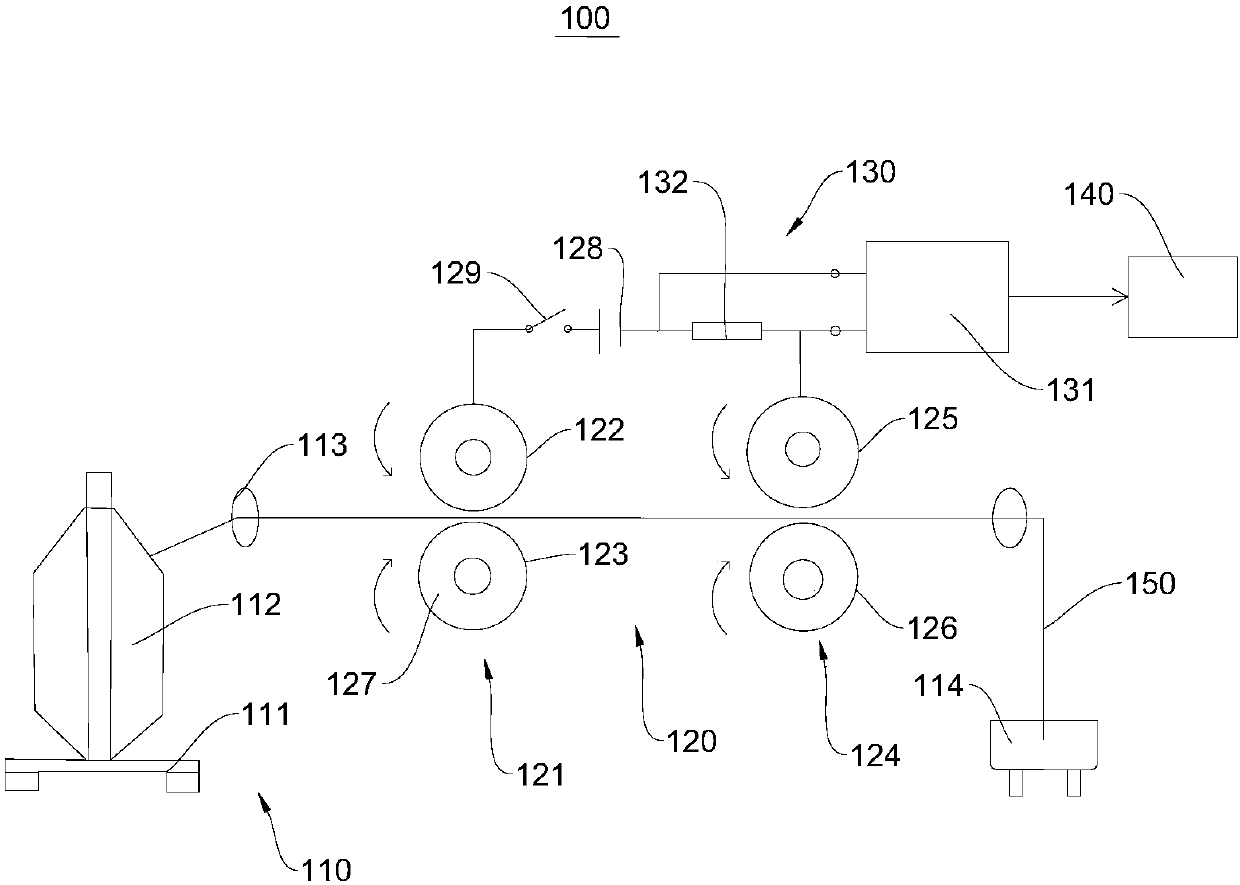

[0033] S1. Pull out the conductive yarn 150 to be tested to the evenness testing device 100 .

[0034] Specifically, the evenness testing device 100 includes a conveying device 110 , an electrode system 120 , a data acquisition system 130 and a computer 140 . The electrode system 120 is set on the delivery device 110 , the data collection system 130 is electrically connected to the electrode system 120 , and the computer 140 is connected to the data collection system 130 by communication.

[0035] Conductive yarn 150 is different from traditional yarns. Conductive short fibers or filaments are added during the weaving process to form conductive blended yarns or pure spinning yarns. Since conductive fibers are electronically conductive, the conductive yarn 150 woven has a relatively low resistance value. The resistance of th...

no. 2 example

[0062] This embodiment provides a method for testing the evenness of evenness, which is basically the same as the first embodiment, except that the data acquisition system collects the current signal corresponding to the conductive yarn, and sends the current signal to the computer. The computer calculates the evenness of the conductive yarn according to the received current signal.

[0063] Specifically, the following steps are included:

[0064] Pull out the conductive yarn to be tested to the evenness testing device, wherein the evenness testing device includes a conveying device, an electrode system, a data acquisition system and a computer, the electrode system is arranged on the conveying device, and the electrode system includes a first electrode and The second electrode, the data acquisition system is electrically connected to the electrode system, and the computer is connected to the data acquisition system by communication;

[0065] connecting the conductive yarn to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com