Machining trajectory planning method of variable tool machining path with equal residual height

A technology of equal residual height and machining trajectory, applied in the direction of digital control, electrical program control, etc., can solve problems such as the discussion of the problem of jointing tool marks, and achieve the effects of ensuring processing quality, reducing jointing tool marks, and high-precision and efficient machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The specific embodiments of the present invention will be described in detail with reference to the technical solutions and the accompanying drawings.

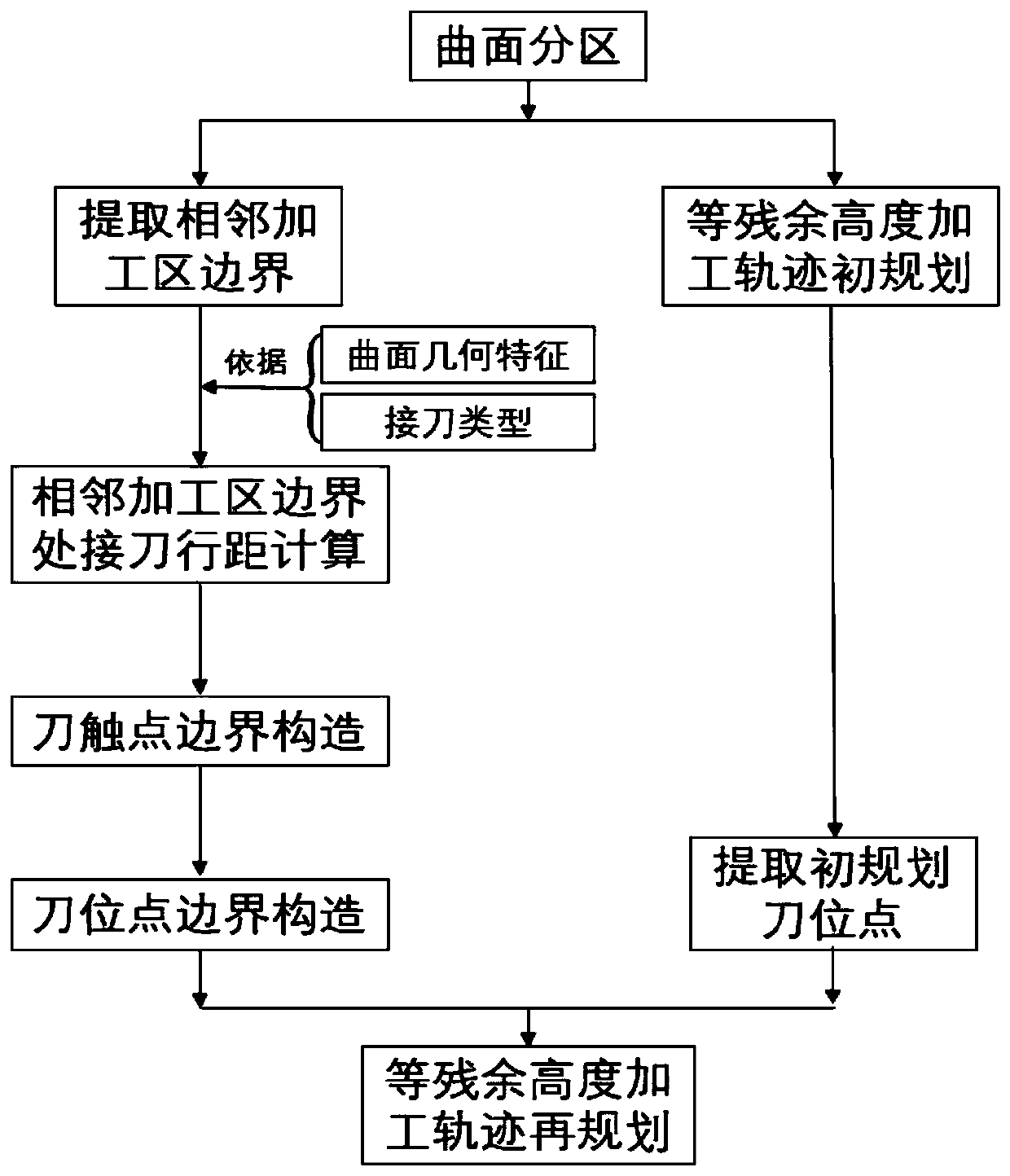

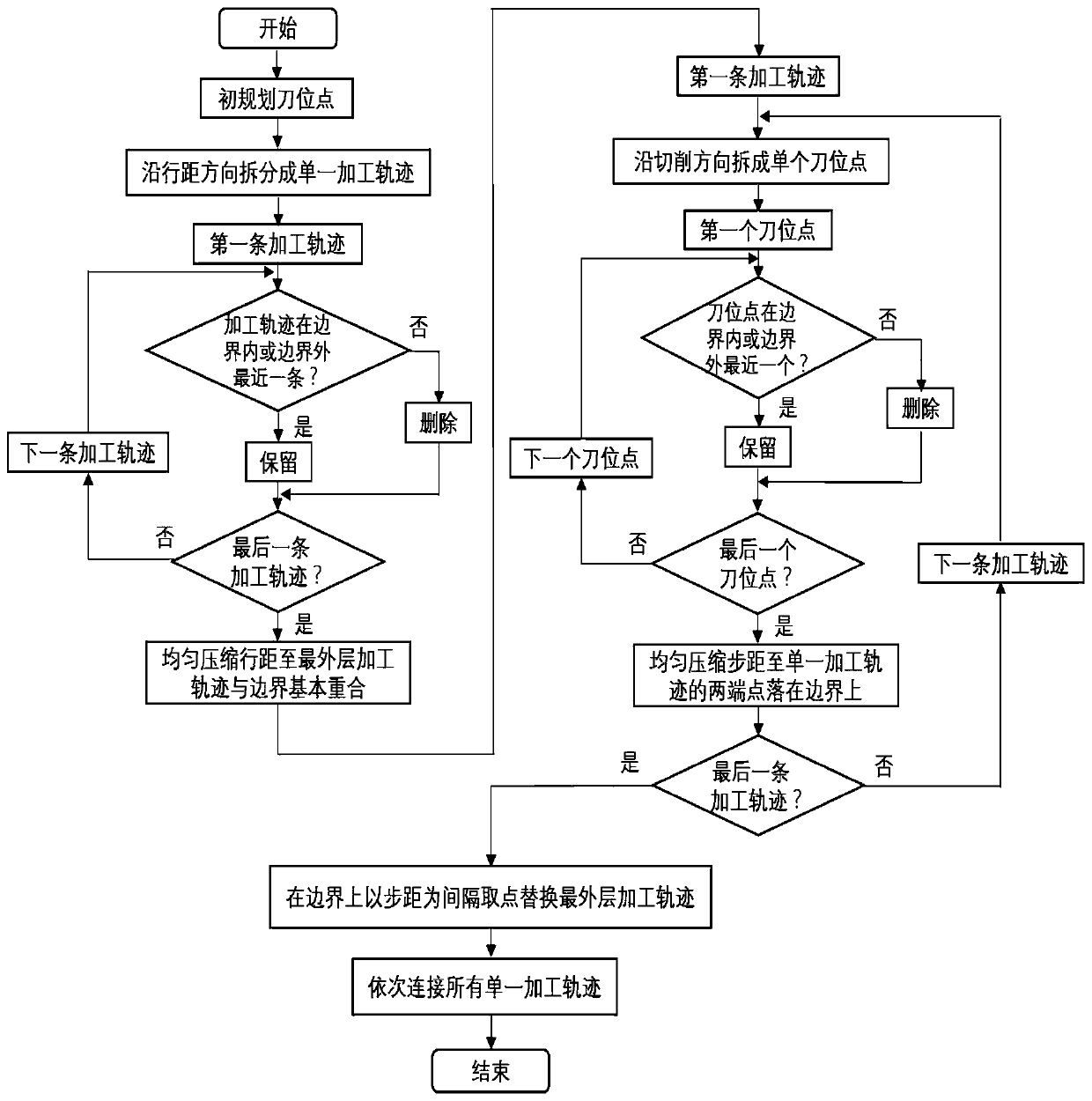

[0094] When the surface is divided into different cutting tools, the initial planning of the processing path is carried out separately for each processing area, resulting in obvious tool marks at the boundary of adjacent processing areas, which seriously affects the surface processing quality. In view of this situation, in order to reduce the tool marks at the boundary of the adjacent processing area, a method for planning the machining path of the surface area with equal residual height and variable tool machining was invented. The overall process is shown in the appendix. figure 1 shown.

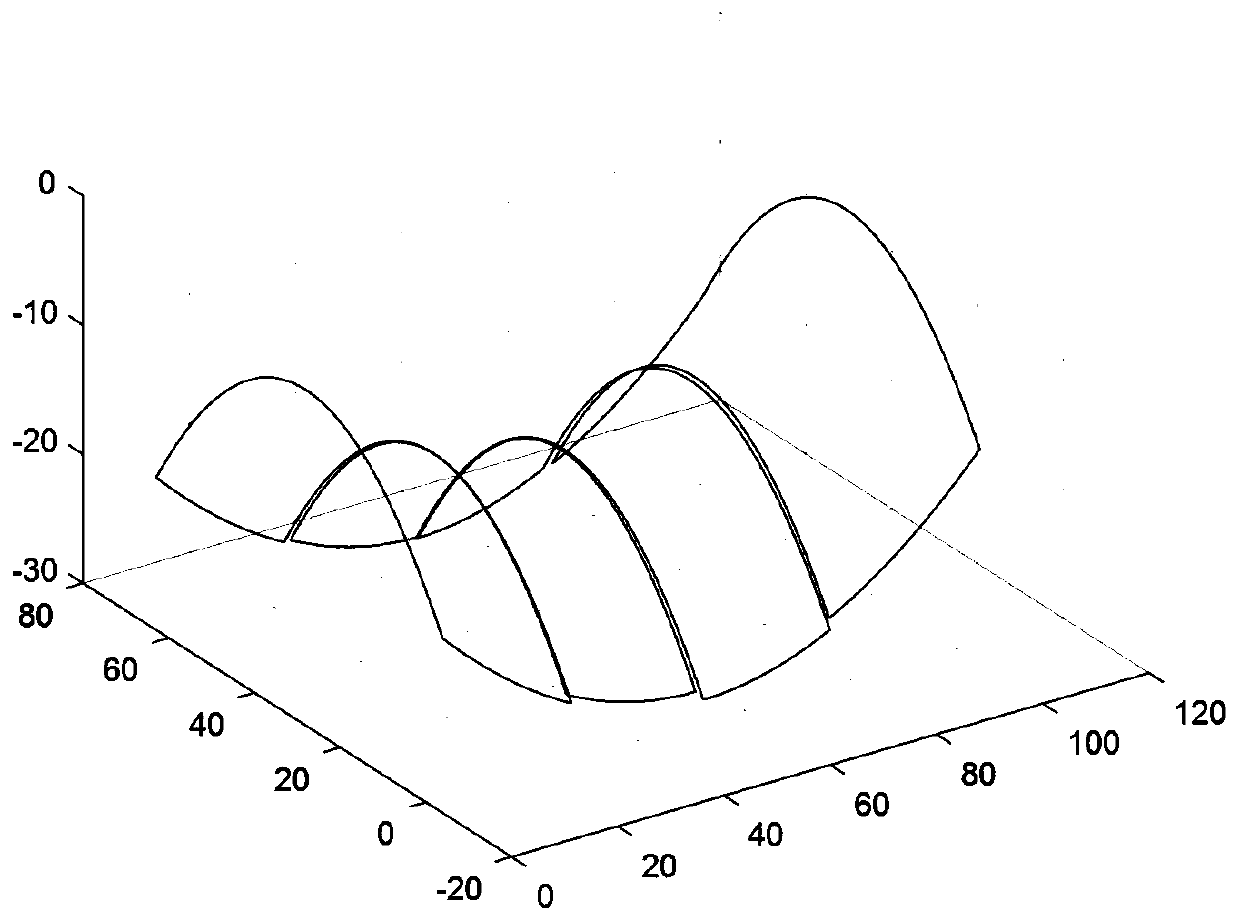

[0095] Taking the saddle surface milling with different milling cutters as an example, with the help of UG software and MATLAB software, the implementation process of the present invention is described in detail.

[0096] First, us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com