Ultra-small-size glue-filling surface-mount LED packaging unit

A technology of LED packaging and adhesive patch, applied in electrical components, electric solid devices, circuits, etc., can solve the problem that the LED display cannot be viewed at close range, the light output of high-density LED display is scattered, and the LED display cannot be applied, etc. problem, to achieve the effect of small dot pitch, light concentration, and reduced package size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

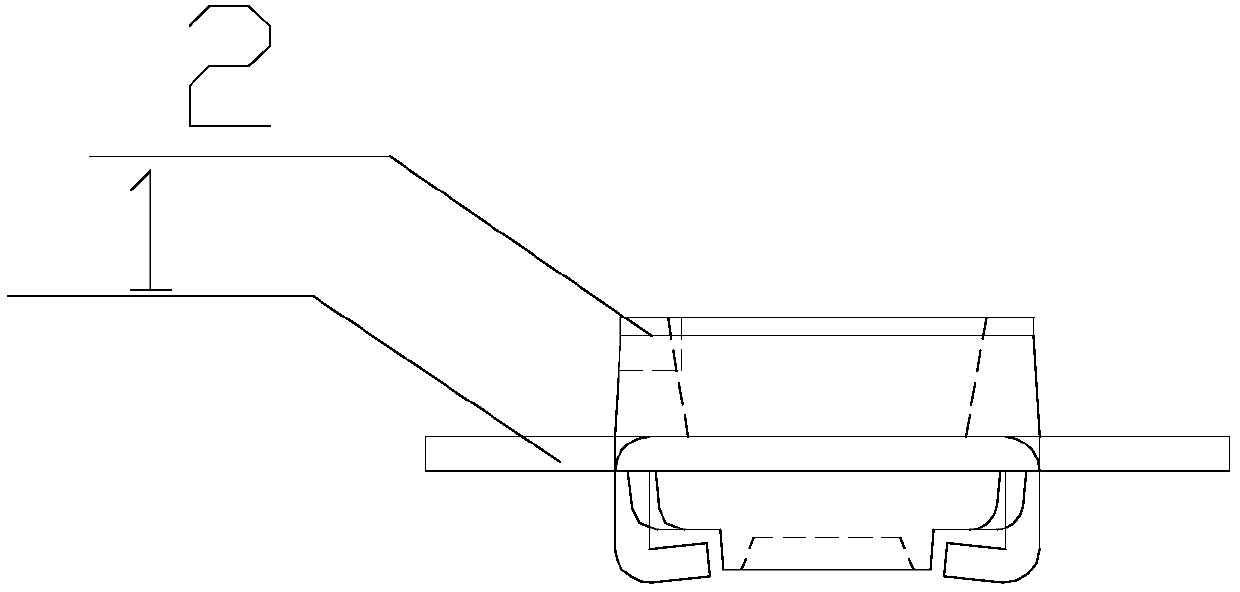

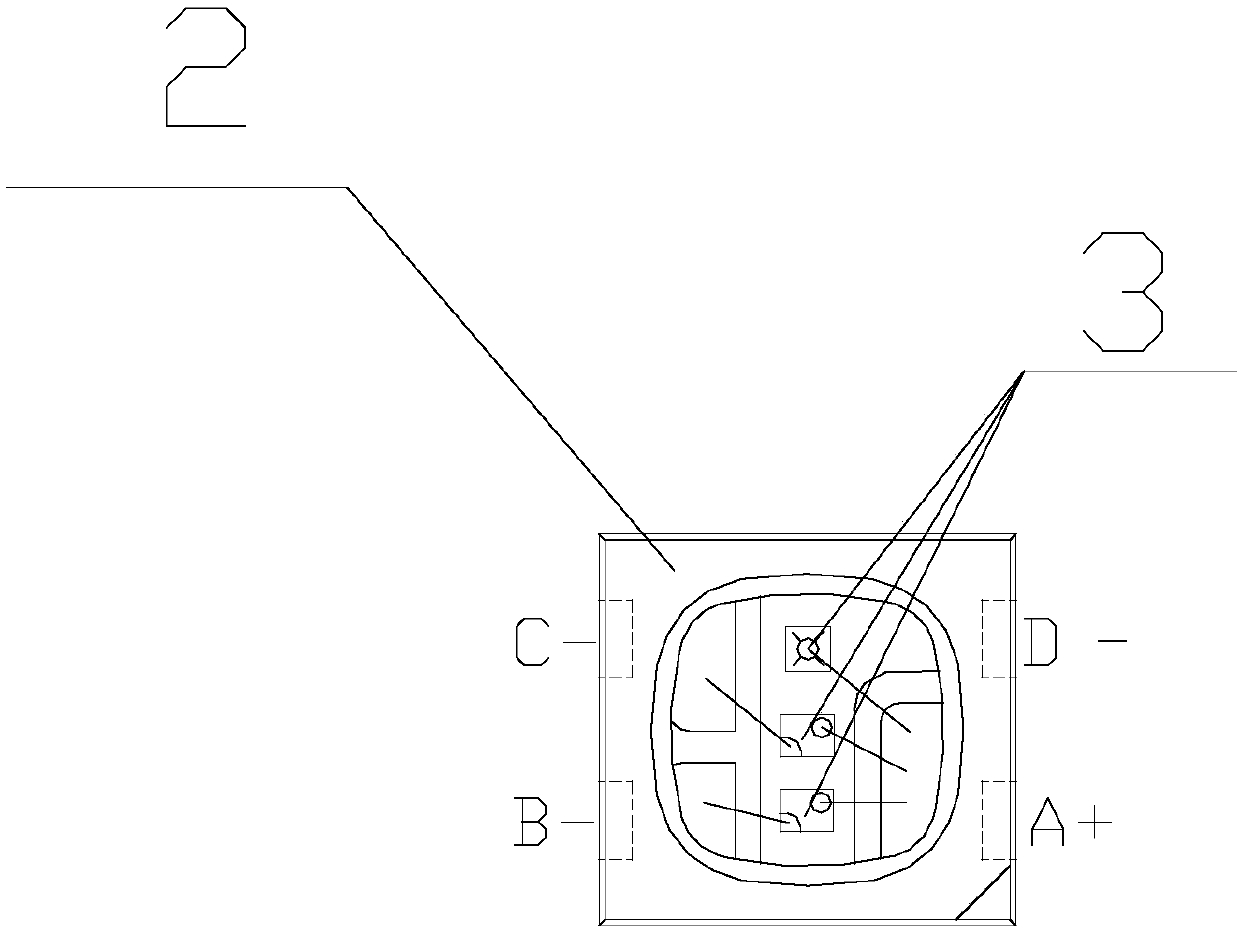

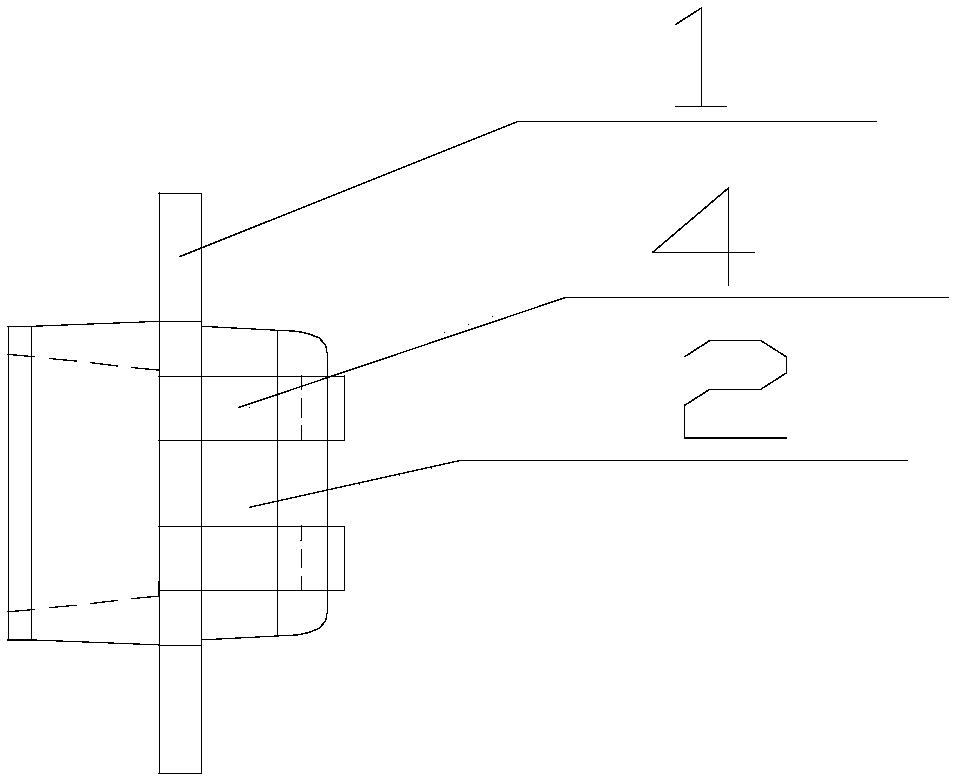

[0020] Such as Figure 1-2 As shown, the present invention includes a packaging support 1, a packaging bowl 2 installed in the middle of the packaging support 1, a wire bonding area 4 and a chip 3 packaged in the packaging bowl 2. There are many chips 3, all located in the same On a plane and arranged on the same straight line; the packaged cup 2 is filled with glue, and a plurality of welding wire areas 4 are arranged at the bottom of the packaged cup 2 . The chip of this embodiment has three chips of red, green and blue, which are arranged in a line from top to bottom. , which avoids the drawbacks of the existing character-shaped chip arrangement, where the three chips block light from each other at different angles in the horizontal direction, and provides better display consistency for the display screen.

Embodiment 2

[0022] Such as Figure 2-3 As shown, this embodiment is based on the embodiment 1, and the preferred specific structure is as follows: the wire bonding area 4 on the packaging cup 2 is distributed symmetrically, and the bottom of the wire bonding area 4 is connected to the packaging bracket 1 . The bracket used is an all-black bracket, and the welding line area can be retracted to effectively avoid solder reflection in the welding line area. Compared with full-color Chip LEDs, it has high contrast, bright colors, better light-gathering effect, and softer light. The display effect is delicate and the color reproduction is high, fully meeting the quality requirements of high-end LED displays.

Embodiment 3

[0024] Such as figure 1 As shown, this embodiment adds the following technical features on the basis of any one of the above embodiments: the bonding wire area 4 includes a positive electrode bonding wire area and three negative electrode bonding wire areas, and the positive electrode bonding wire area A+ is located on the right side of the packaging bowl cup 2 Below, there are two negative electrode bonding areas B- and C- on the left side of the packaged cup 2 and a negative electrode bonding area D- on the upper right side of the packaged cup 2 . The positive electrodes of the pins on each chip 3 are welded in the same positive electrode bonding area, and the negative electrodes of the pins are welded in different negative electrode bonding areas. The negative poles of the pins of all chips 3 arranged on the same straight line are welded clockwise in the negative electrode welding line area. The packaging support 1 is rectangular and crosses the middle of the packaging cup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com