Heat dissipation device for motor

A heat dissipation device and motor technology, applied in electromechanical devices, casings/covers/supports, electrical components, etc., can solve problems such as motor damage, high risk, and automation equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

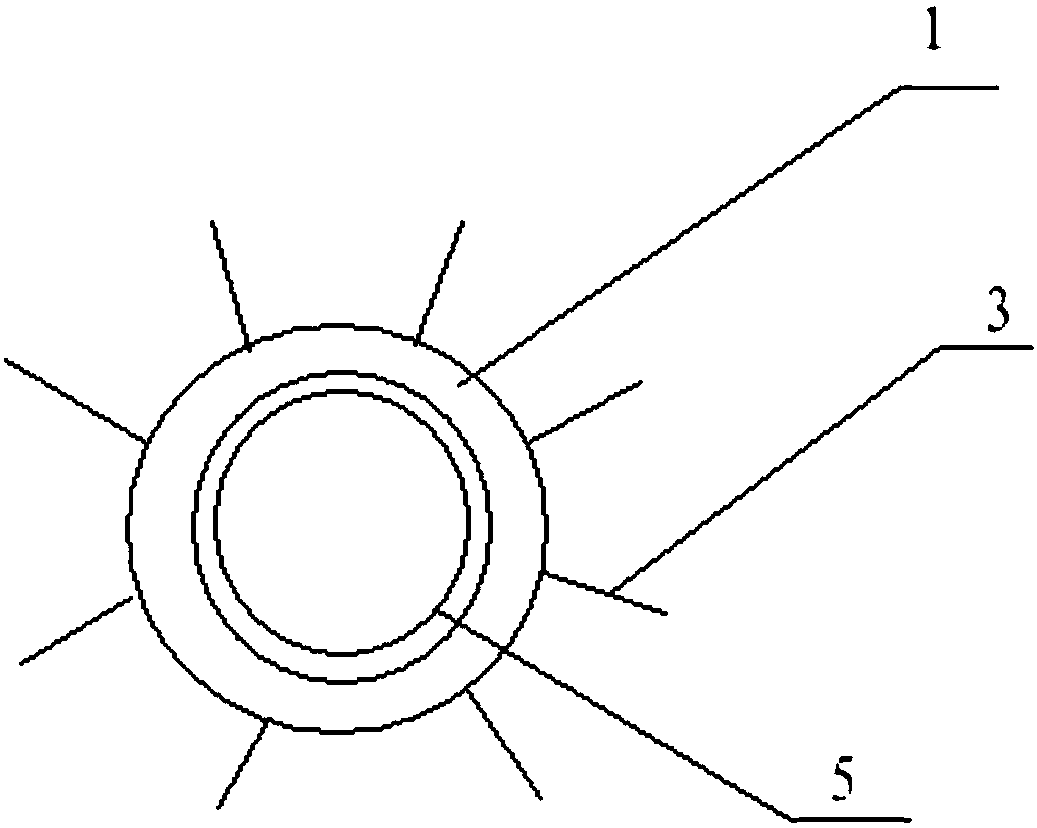

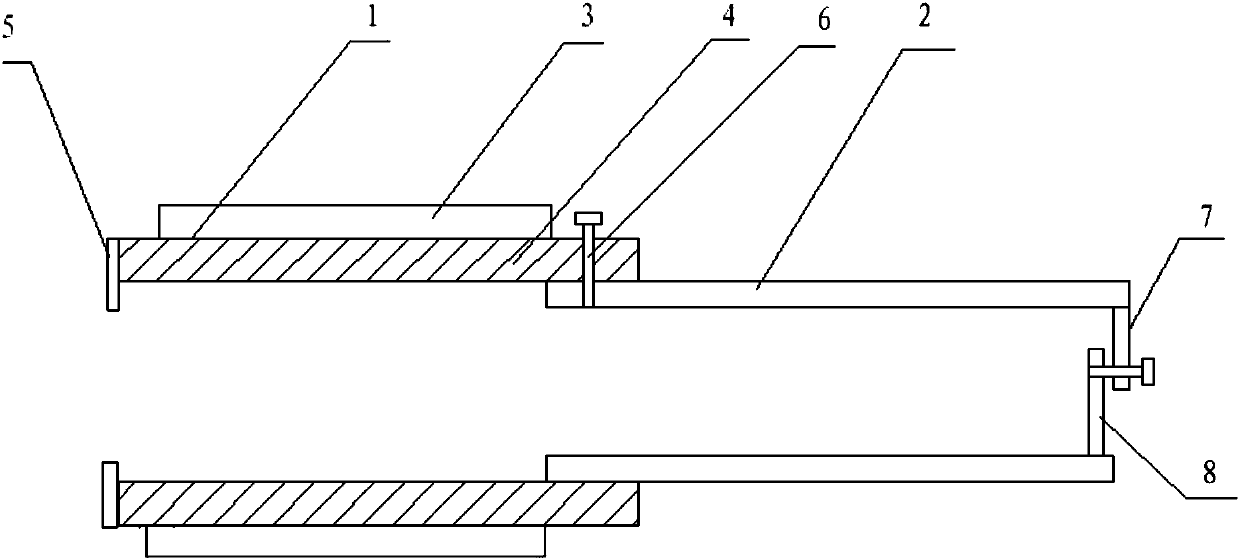

[0022] Such as Figure 1-2 As shown, a heat dissipation device for a motor includes a shell assembly and a heat conduction sheet;

[0023] The housing assembly includes a coaxial first housing 1 and a second housing 2, both of which are open at the top and bottom; the first housing 1 is a cavity structure, including an inner wall and a The outer wall in contact with the outside world is provided with several cooling fins 3 extending along its axial direction, and each cooling fin 3 is arranged at equal intervals; preferably, the cooling fins 3 are in the shape of a wide middle and small ends. , which can facilitate the dissipation of heat outward;

[0024] The length of the second housing 2 is less than the length of the first housing 1, which is a single-layer structure, and its outer wall is attached to the inner wall of the first housing 1, and can slide along the inner wall of the first housing 1, Its inner diameter matches the outer diameter of the motor to be dissipate...

Embodiment 2

[0032] Based on Embodiment 1, in this embodiment, in order to improve the heat dissipation performance of the heat sink, the end of the first housing 1 away from the second housing is provided with a baffle 5, and the baffle 5 is along the first The radial extension of the shell 1 partially covers the opening at the end of the first shell 1; the first shell 1 is also provided with a positioning pin 6, and the positioning pin 6 is arranged perpendicular to the first shell 1, And penetrate through the outer wall and inner wall of the first housing 1 to limit the movement of the second housing 2 .

[0033] Further, symmetrically arranged first rotating pieces 7 and second rotating pieces 8 are hinged on the edge of the end of the second casing 2 away from the first casing, and the first rotating pieces 7 and the second rotating pieces 8 connected by screws,

[0034] In actual use, first attach one end of the motor to be dissipated to the baffle, and then adjust the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com