Grinding roller with a cooling device

A technology of cooling device and grinding roller, applied in the field of grinding roller, can solve the problems of expensive installation space and assembly, difficulty in manufacturing and high production cost, and achieve the effect of saving cost and time, saving cost and reducing parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

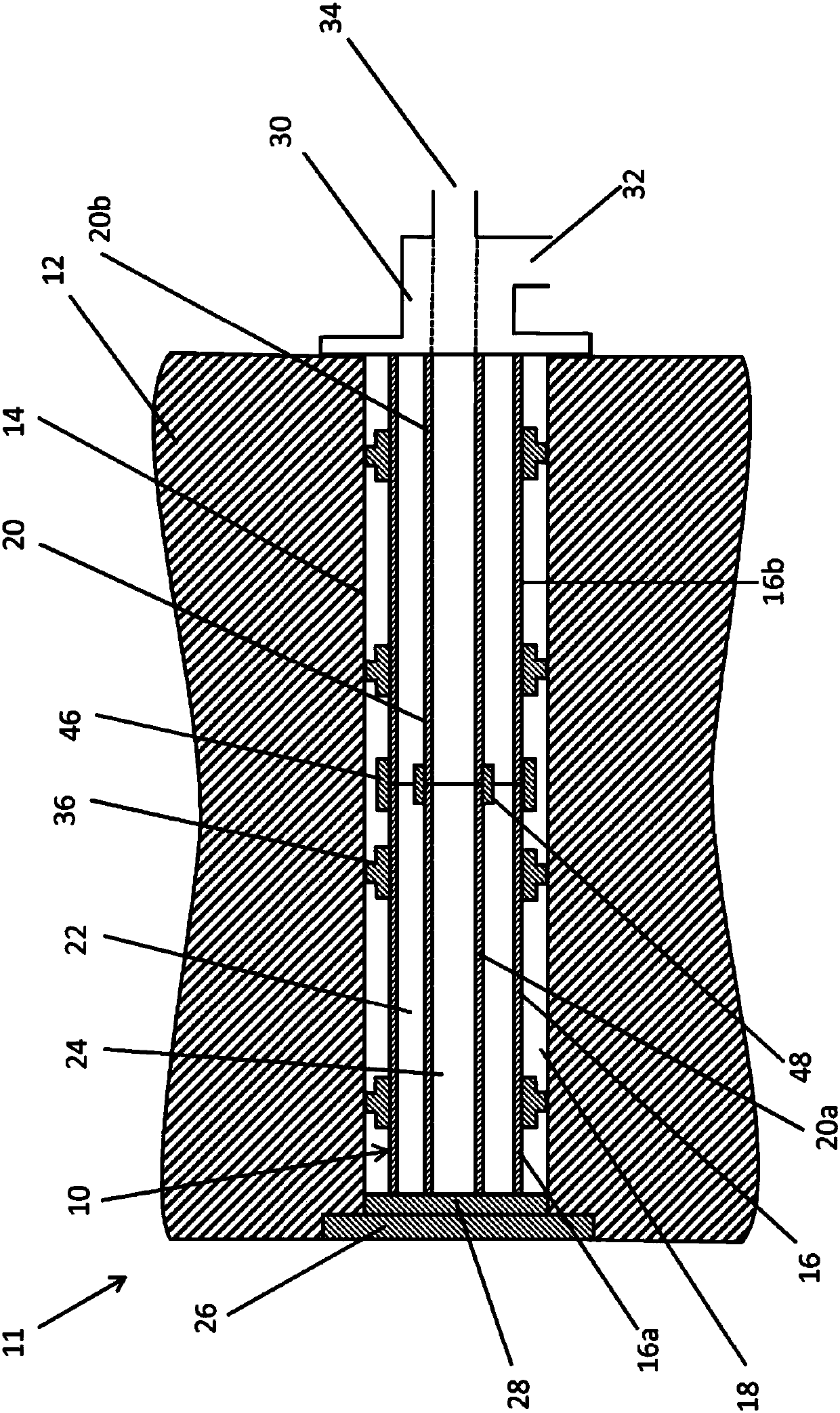

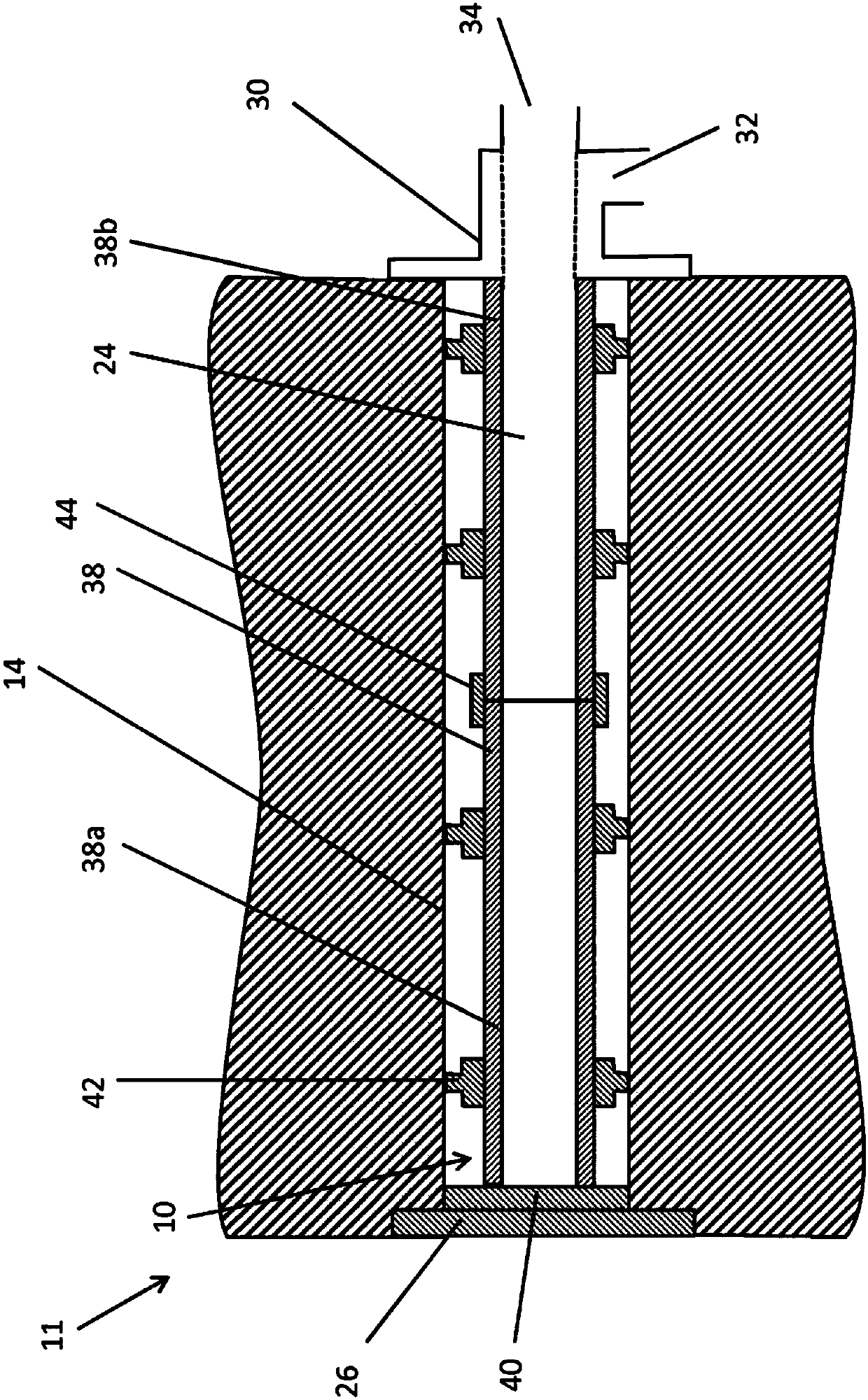

[0026] figure 1 A section is shown of a grinding roller shaft 12 on which grinding rollers are mounted in a manner not shown. Roller shaft 12 includes an axial bore 14 extending through roll shaft 12 . Furthermore, the grinding roller shaft 12 includes a cooling device 10 arranged in a bore 14 . The cooling device 10 comprises a first tube 16 arranged in and coaxially with the bore 14 . The outer diameter of the first tube 16 is smaller than the inner diameter of the hole 14 , so that a first conduit 18 for guiding the coolant is formed between the inner surface of the hole 14 and the outer surface of the tube 16 . A second tube 20 is arranged coaxially with the first tube. The second tube 20 has a smaller diameter than the first tube 16 and is arranged within the first tube 16 such that a gap 22 is formed between the first tube 16 and the second tube 20 . A second pipe 24 for guiding coolant is formed inside the second pipe 20 . The first tube 16 and the second tube 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com