Poultry cage cleaning machine

A technology for cleaning machines and poultry cages, applied in the field of poultry cage cleaning machines, can solve the problems of unguaranteed sanitation and safety, poor working environment conditions, waste of water resources, etc., and achieves improved working environment conditions, sanitation and safety assurance, and cleaning efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

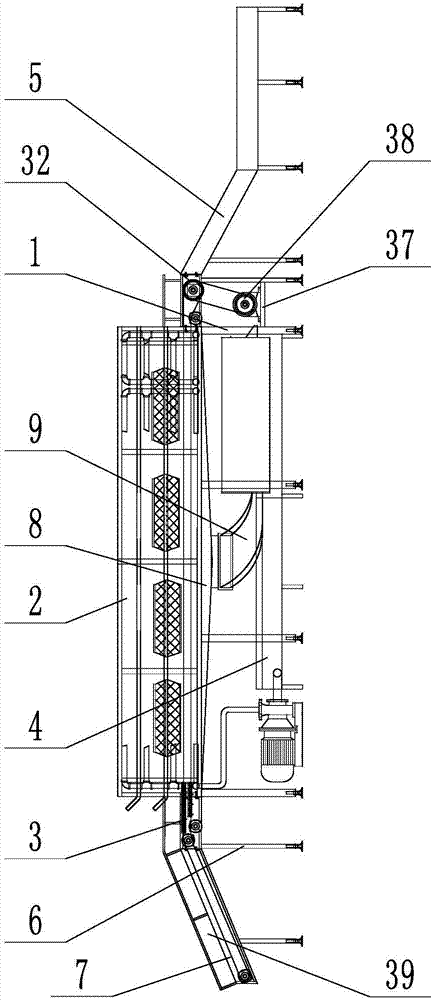

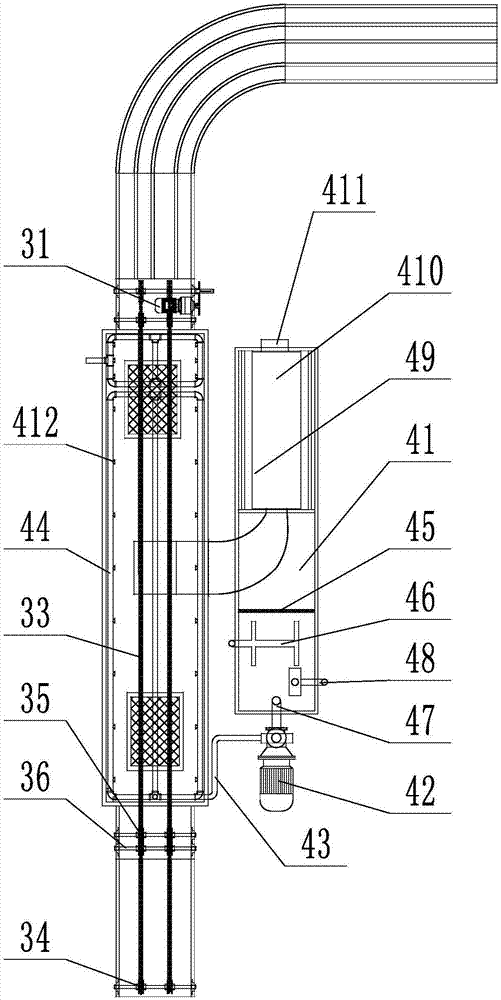

[0011] like figure 1 and 2 As shown, the present invention includes a main frame 1, a cleaning spray chamber 2, a chain conveying mechanism 3, a water supply system 4 and a slideway 5, the top surface of the main frame 1 is equipped with a cleaning spray chamber 2, and the chain conveyor The conveying mechanism 3 traverses the cleaning and spraying chamber 2 and is installed on the main frame 1. The water pump water supply system 4 is installed on the lower left and inside of the cleaning and spraying chamber 2. The slideway 5 and the right end of the chain conveying mechanism 3 Connected and installed on the main frame 1, the left end of the main frame 1 is equipped with a poultry cage conveying bin 7 connected to the left end of the cleaning spray room 2 through the feet 6, and the bottom of the cleaning spray room 2 is equipped with a water tank 8. A return pipe 9 is installed at the bottom of the water receiving tank 8 .

[0012] The chain conveying mechanism 3 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com